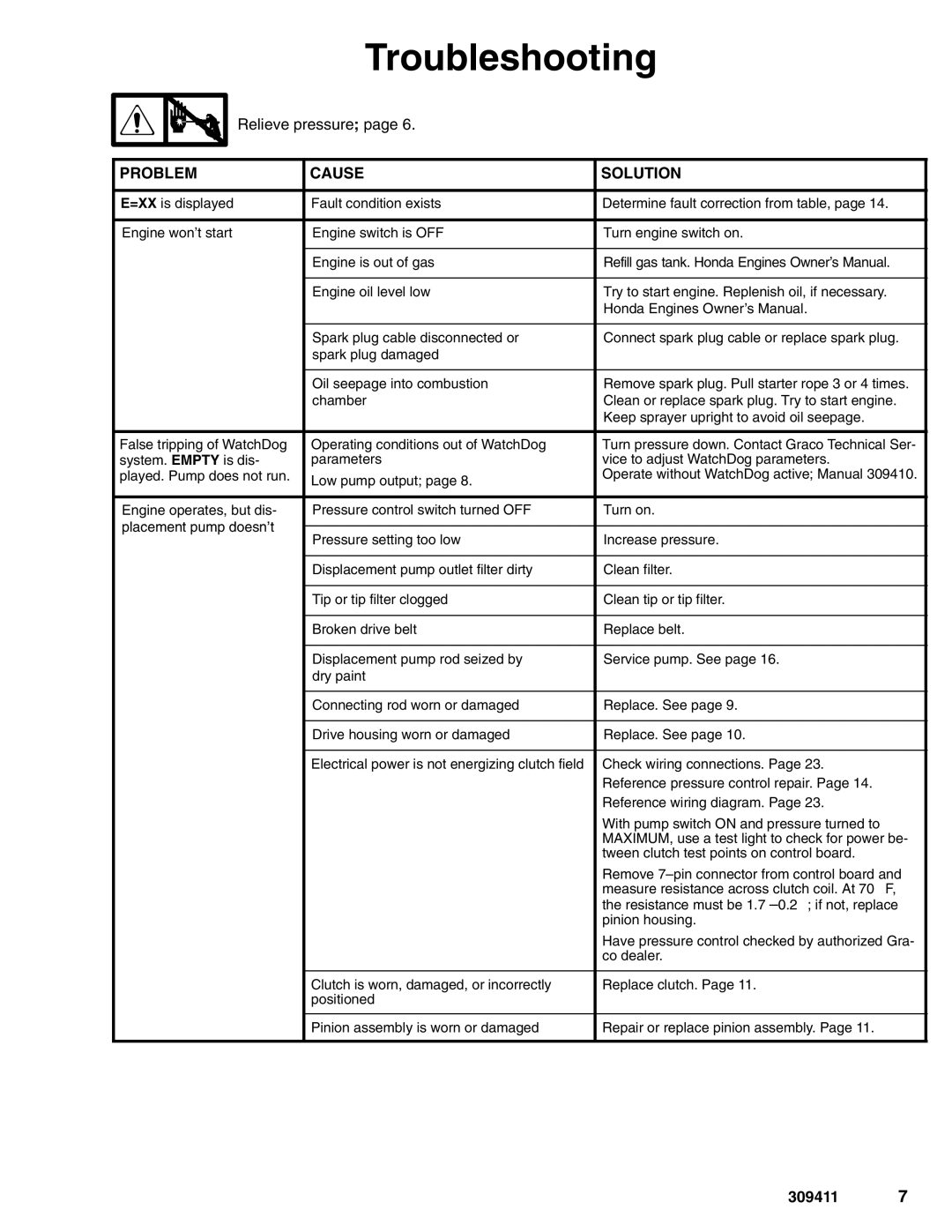

Troubleshooting

Relieve pressure; page 6.

PROBLEM | CAUSE | SOLUTION | |

|

|

| |

E=XX is displayed | Fault condition exists | Determine fault correction from table, page 14. | |

|

|

| |

Engine won’t start | Engine switch is OFF | Turn engine switch on. | |

|

|

| |

| Engine is out of gas | Refill gas tank. Honda Engines Owner’s Manual. | |

|

|

| |

| Engine oil level low | Try to start engine. Replenish oil, if necessary. | |

|

| Honda Engines Owner’s Manual. | |

|

|

| |

| Spark plug cable disconnected or | Connect spark plug cable or replace spark plug. | |

| spark plug damaged |

| |

|

|

| |

| Oil seepage into combustion | Remove spark plug. Pull starter rope 3 or 4 times. | |

| chamber | Clean or replace spark plug. Try to start engine. | |

|

| Keep sprayer upright to avoid oil seepage. | |

|

|

| |

False tripping of WatchDog | Operating conditions out of WatchDog | Turn pressure down. Contact Graco Technical Ser- | |

system. EMPTY is dis- | parameters | vice to adjust WatchDog parameters. | |

played. Pump does not run. | Low pump output; page 8. | Operate without WatchDog active; Manual 309410. | |

|

| ||

|

|

| |

Engine operates, but dis- | Pressure control switch turned OFF | Turn on. | |

placement pump doesn’t |

|

| |

Pressure setting too low | Increase pressure. | ||

| |||

|

|

| |

| Displacement pump outlet filter dirty | Clean filter. | |

|

|

| |

| Tip or tip filter clogged | Clean tip or tip filter. | |

|

|

| |

| Broken drive belt | Replace belt. | |

|

|

| |

| Displacement pump rod seized by | Service pump. See page 16. | |

| dry paint |

| |

|

|

| |

| Connecting rod worn or damaged | Replace. See page 9. | |

|

|

| |

| Drive housing worn or damaged | Replace. See page 10. | |

|

|

| |

| Electrical power is not energizing clutch field | Check wiring connections. Page 23. | |

|

| Reference pressure control repair. Page 14. | |

|

| Reference wiring diagram. Page 23. | |

|

| With pump switch ON and pressure turned to | |

|

| MAXIMUM, use a test light to check for power be- | |

|

| tween clutch test points on control board. | |

|

| Remove | |

|

| measure resistance across clutch coil. At 70_ F, | |

|

| the resistance must be 1.7 ±0.2Ω; if not, replace | |

|

| pinion housing. | |

|

| Have pressure control checked by authorized Gra- | |

|

| co dealer. | |

|

|

| |

| Clutch is worn, damaged, or incorrectly | Replace clutch. Page 11. | |

| positioned |

| |

|

|

| |

| Pinion assembly is worn or damaged | Repair or replace pinion assembly. Page 11. | |

|

|

|

309411 7