English

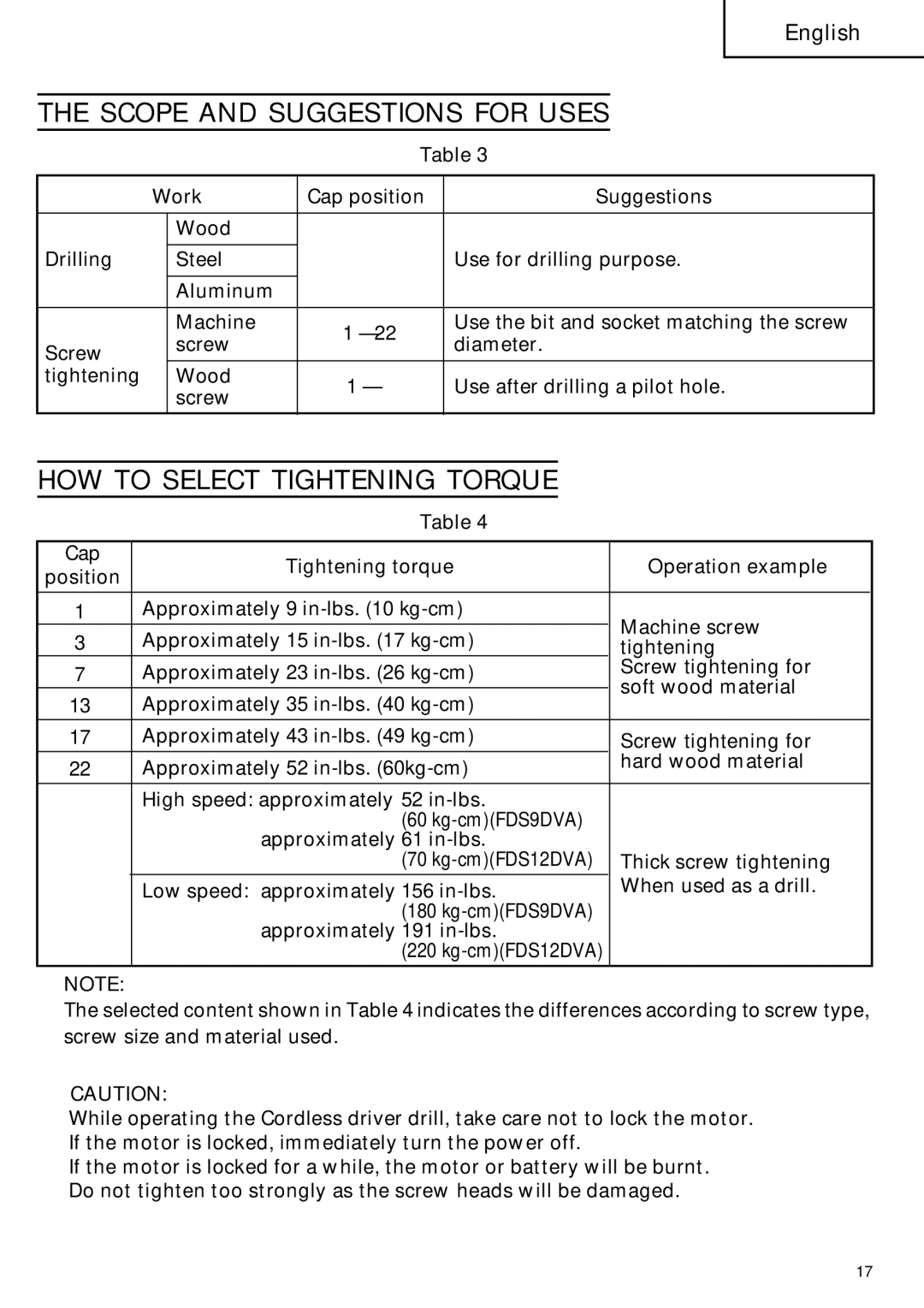

THE SCOPE AND SUGGESTIONS FOR USES

Table 3

| Work | Cap position | Suggestions | |

|

|

|

|

|

|

| Wood |

|

|

|

|

|

|

|

Drilling |

| Steel |

| Use for drilling purpose. |

|

|

|

|

|

|

| Aluminum |

|

|

|

|

|

|

|

|

| Machine | 1 – 22 | Use the bit and socket matching the screw |

Screw |

| screw | diameter. | |

|

| |||

|

|

|

| |

tightening |

| Wood | 1 – | Use after drilling a pilot hole. |

|

| screw | ||

|

|

|

| |

|

|

|

|

|

HOW TO SELECT TIGHTENING TORQUE

Table 4

Cap | Tightening torque | Operation example | |

position | |||

|

| ||

|

|

| |

1 | Approximately 9 | Machine screw | |

3 | Approximately 15 | ||

tightening | |||

7 | Approximately 23 | Screw tightening for | |

|

| soft wood material | |

13 | Approximately 35 | ||

| |||

17 | Approximately 43 | Screw tightening for | |

22 | Approximately 52 | hard wood material | |

| |||

|

|

| |

| High speed: approximately 52 |

| |

| (60 |

| |

| approximately 61 |

| |

| (70 | Thick screw tightening | |

| Low speed: approximately 156 | When used as a drill. | |

| (180 |

| |

| approximately 191 |

| |

| (220 |

|

NOTE:

The selected content shown in Table 4 indicates the differences according to screw type, screw size and material used.

![]() CAUTION:

CAUTION:

●While operating the Cordless driver drill, take care not to lock the motor. If the motor is locked, immediately turn the power off.

If the motor is locked for a while, the motor or battery will be burnt.

●Do not tighten too strongly as the screw heads will be damaged.

17