2.Inspecting the mounting screws:

Regularly inspect all mounting screws and ensure that they are properly tightened. Should any of the screws be loose, retighten them immediately. Failure to do so could result in serious hazard.

3.Inspecting the retainer (Fig.2 and 3)

The retainer may become loose due to excessive use. Always, pay attention to its proper functioning to securely hold the accessory shank portion. If any wear and tear is found, bring this demolition hammer to an authorized service center for maintenance service.

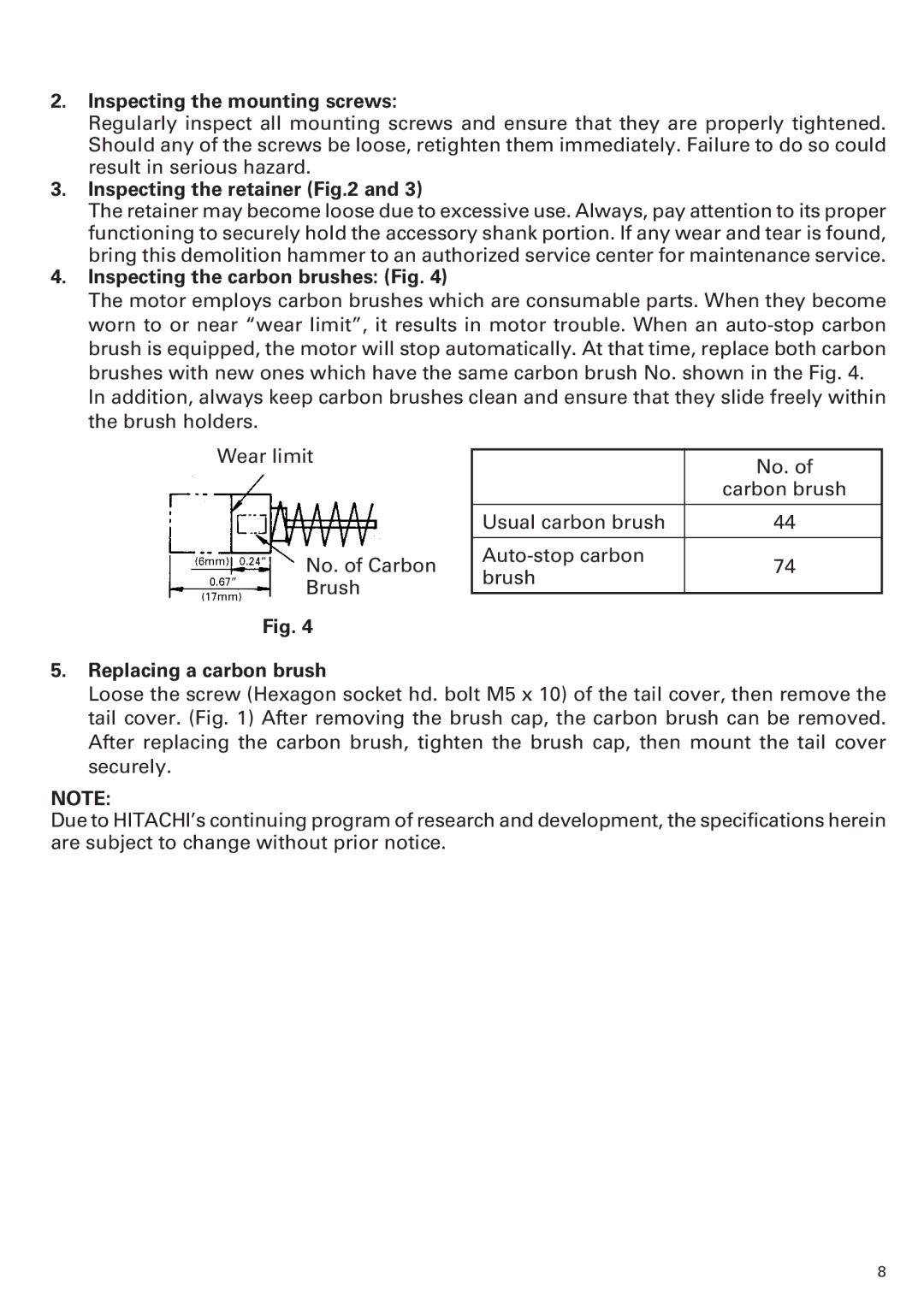

4.Inspecting the carbon brushes: (Fig. 4)

The motor employs carbon brushes which are consumable parts. When they become worn to or near “wear limit”, it results in motor trouble. When an

In addition, always keep carbon brushes clean and ensure that they slide freely within the brush holders.

Wear limit

No. of Carbon

Brush

| No. of | |

| carbon brush | |

|

| |

Usual carbon brush | 44 | |

|

| |

74 | ||

brush | ||

| ||

|

|

Fig. 4

5.Replacing a carbon brush

Loose the screw (Hexagon socket hd. bolt M5 x 10) of the tail cover, then remove the tail cover. (Fig. 1) After removing the brush cap, the carbon brush can be removed. After replacing the carbon brush, tighten the brush cap, then mount the tail cover securely.

NOTE:

Due to HITACHI’s continuing program of research and development, the specifications herein are subject to change without prior notice.

8