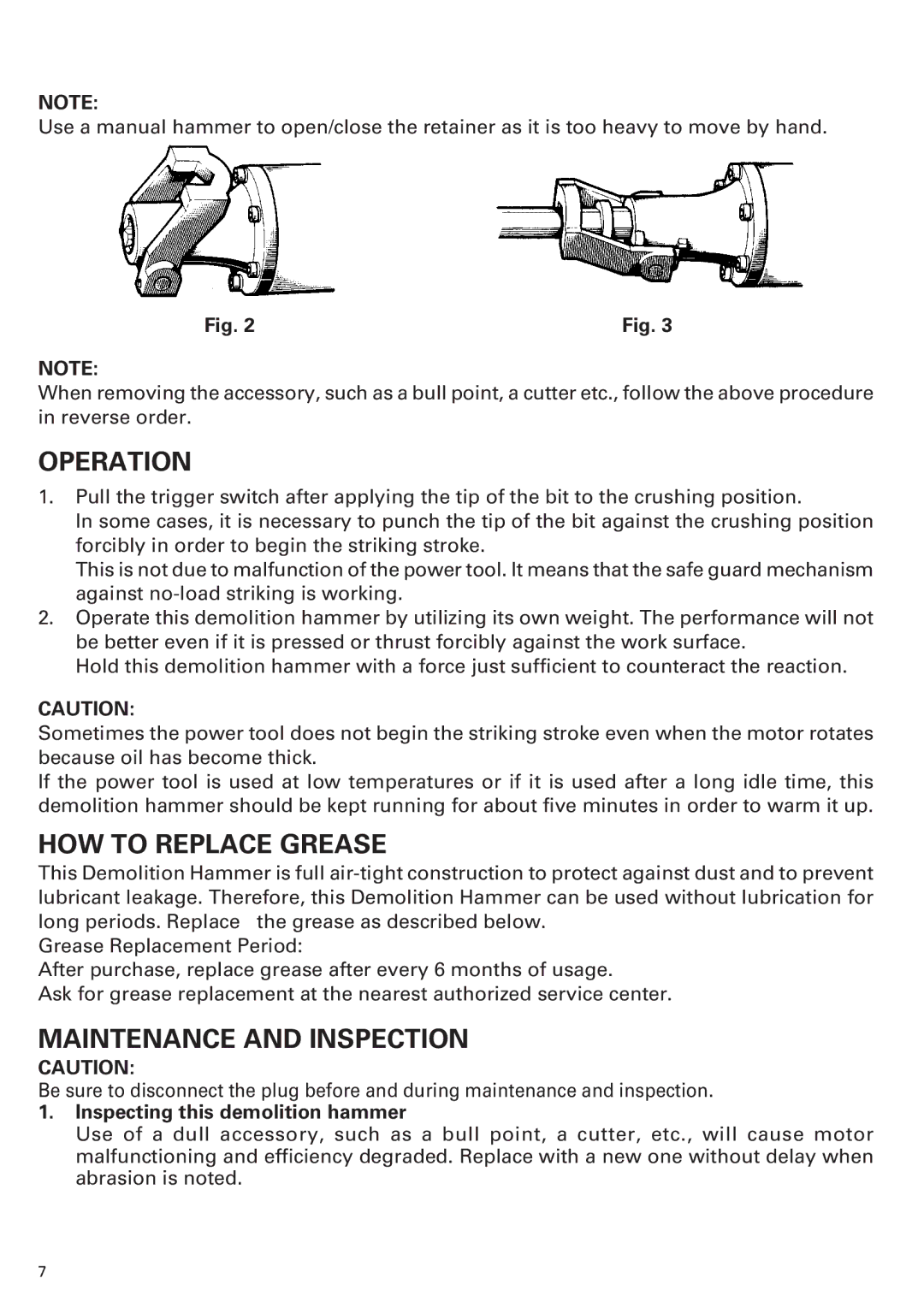

NOTE:

Use a manual hammer to open/close the retainer as it is too heavy to move by hand.

Fig. 2 | Fig. 3 |

NOTE:

When removing the accessory, such as a bull point, a cutter etc., follow the above procedure in reverse order.

OPERATION

1.Pull the trigger switch after applying the tip of the bit to the crushing position.

In some cases, it is necessary to punch the tip of the bit against the crushing position forcibly in order to begin the striking stroke.

This is not due to malfunction of the power tool. It means that the safe guard mechanism against

2.Operate this demolition hammer by utilizing its own weight. The performance will not be better even if it is pressed or thrust forcibly against the work surface.

Hold this demolition hammer with a force just sufficient to counteract the reaction.

CAUTION:

Sometimes the power tool does not begin the striking stroke even when the motor rotates because oil has become thick.

If the power tool is used at low temperatures or if it is used after a long idle time, this demolition hammer should be kept running for about five minutes in order to warm it up.

HOW TO REPLACE GREASE

This Demolition Hammer is full

Grease Replacement Period:

After purchase, replace grease after every 6 months of usage.

Ask for grease replacement at the nearest authorized service center.

MAINTENANCE AND INSPECTION

CAUTION:

Be sure to disconnect the plug before and during maintenance and inspection.

1.Inspecting this demolition hammer

Use of a dull accessory, such as a bull point, a cutter, etc., will cause motor malfunctioning and efficiency degraded. Replace with a new one without delay when abrasion is noted.

7