.A complete Parts List is available at www.HobartWelders.com

SECTION 5 − INSTALLATION

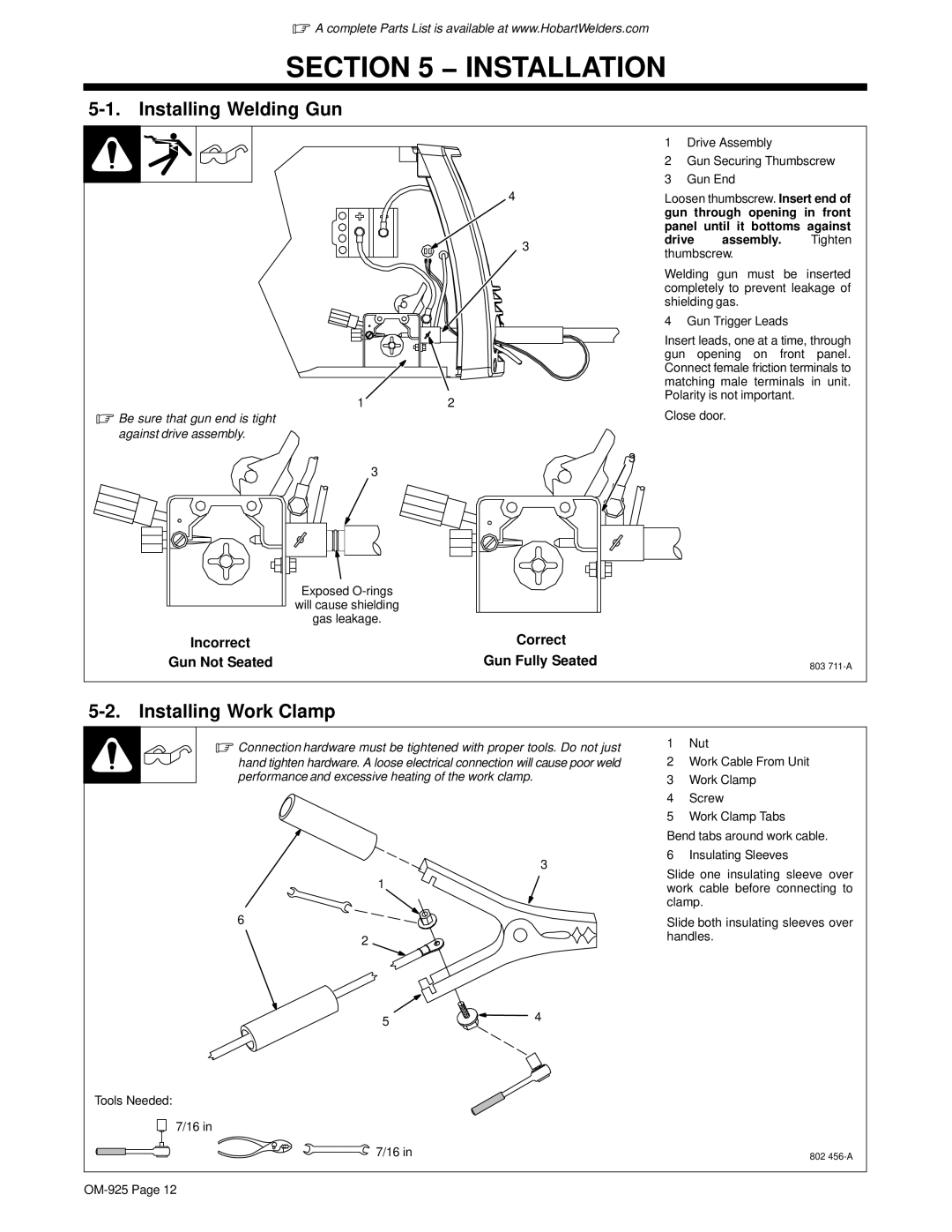

5-1. Installing Welding Gun

4

3

12

.Be sure that gun end is tight against drive assembly.

3

3

Exposed

will cause shielding

gas leakage.

1Drive Assembly

2Gun Securing Thumbscrew

3Gun End

Loosen thumbscrew. Insert end of gun through opening in front panel until it bottoms against

drive assembly. Tighten thumbscrew.

Welding gun must be inserted completely to prevent leakage of shielding gas.

4 Gun Trigger Leads

Insert leads, one at a time, through gun opening on front panel. Connect female friction terminals to matching male terminals in unit. Polarity is not important.

Close door.

Incorrect | Correct |

|

Gun Not Seated | Gun Fully Seated | 803 |

5-2. Installing Work Clamp

. Connection hardware must be tightened with proper tools. Do not just hand tighten hardware. A loose electrical connection will cause poor weld performance and excessive heating of the work clamp.

3

1

6

2

5 | 4 |

|

Tools Needed:

7/16 in

7/16 in

1Nut

2Work Cable From Unit

3Work Clamp

4Screw

5Work Clamp Tabs

Bend tabs around work cable.

6 Insulating Sleeves

Slide one insulating sleeve over work cable before connecting to clamp.

Slide both insulating sleeves over handles.

802