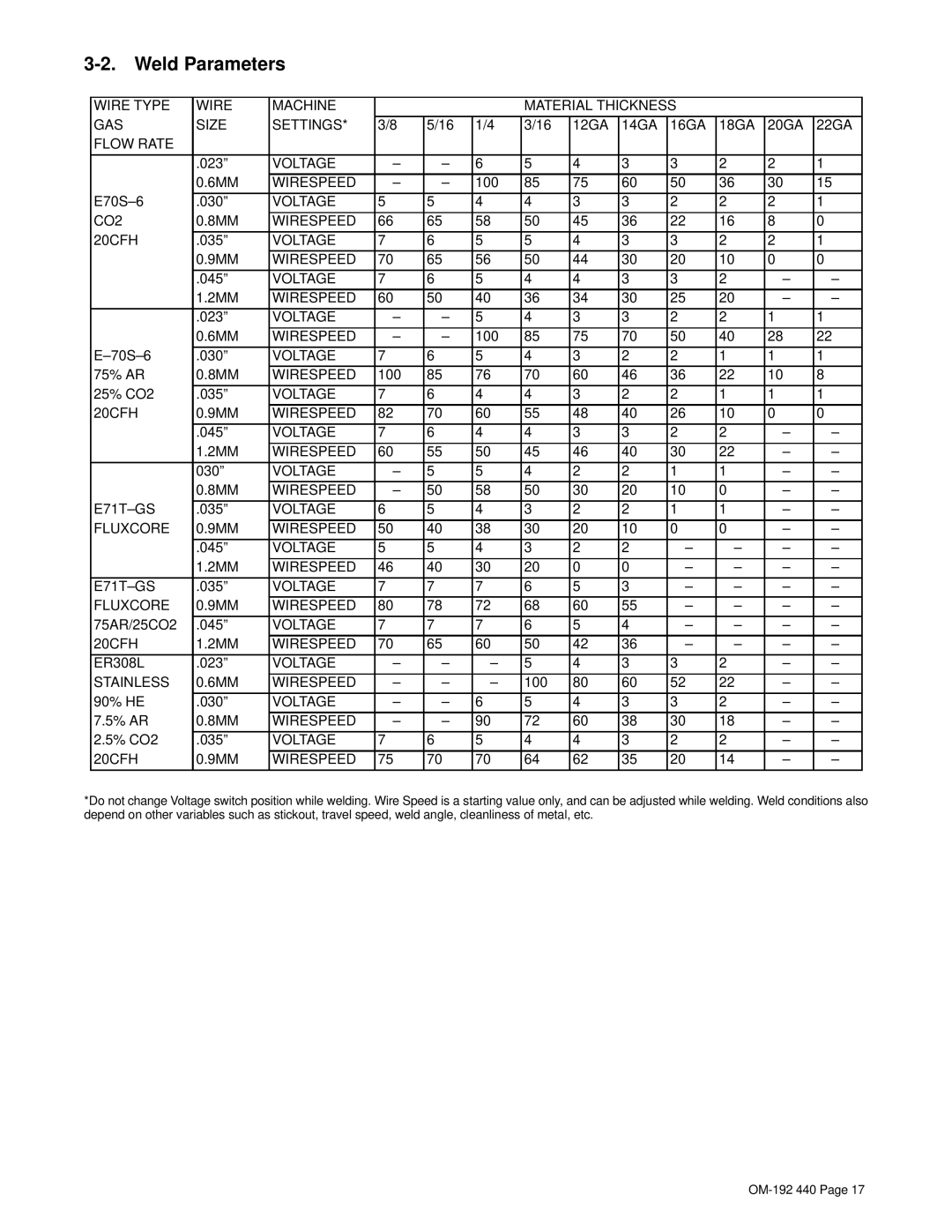

3-2. Weld Parameters

WIRE TYPE | WIRE | MACHINE |

|

|

| MATERIAL THICKNESS |

|

|

| |||

GAS | SIZE | SETTINGS* | 3/8 | 5/16 | 1/4 | 3/16 | 12GA | 14GA | 16GA | 18GA | 20GA | 22GA |

FLOW RATE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| .023” | VOLTAGE | – | – | 6 | 5 | 4 | 3 | 3 | 2 | 2 | 1 |

| 0.6MM | WIRESPEED | – | – | 100 | 85 | 75 | 60 | 50 | 36 | 30 | 15 |

.030” | VOLTAGE | 5 | 5 | 4 | 4 | 3 | 3 | 2 | 2 | 2 | 1 | |

CO2 | 0.8MM |

|

|

|

|

|

|

|

|

|

|

|

WIRESPEED | 66 | 65 | 58 | 50 | 45 | 36 | 22 | 16 | 8 | 0 | ||

20CFH | .035” | VOLTAGE | 7 | 6 | 5 | 5 | 4 | 3 | 3 | 2 | 2 | 1 |

| 0.9MM | WIRESPEED | 70 | 65 | 56 | 50 | 44 | 30 | 20 | 10 | 0 | 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| .045” | VOLTAGE | 7 | 6 | 5 | 4 | 4 | 3 | 3 | 2 | – | – |

| 1.2MM | WIRESPEED | 60 | 50 | 40 | 36 | 34 | 30 | 25 | 20 | – | – |

| .023” | VOLTAGE | – | – | 5 | 4 | 3 | 3 | 2 | 2 | 1 | 1 |

| 0.6MM |

|

|

|

|

|

|

|

|

|

|

|

| WIRESPEED | – | – | 100 | 85 | 75 | 70 | 50 | 40 | 28 | 22 | |

|

|

|

|

|

|

|

|

|

|

|

| |

.030” | VOLTAGE | 7 | 6 | 5 | 4 | 3 | 2 | 2 | 1 | 1 | 1 | |

75% AR | 0.8MM | WIRESPEED | 100 | 85 | 76 | 70 | 60 | 46 | 36 | 22 | 10 | 8 |

25% CO2 |

|

|

|

|

|

|

|

|

|

|

|

|

.035” | VOLTAGE | 7 | 6 | 4 | 4 | 3 | 2 | 2 | 1 | 1 | 1 | |

20CFH | 0.9MM | WIRESPEED | 82 | 70 | 60 | 55 | 48 | 40 | 26 | 10 | 0 | 0 |

| .045” | VOLTAGE | 7 | 6 | 4 | 4 | 3 | 3 | 2 | 2 | – | – |

| 1.2MM |

|

|

|

|

|

|

|

|

|

|

|

| WIRESPEED | 60 | 55 | 50 | 45 | 46 | 40 | 30 | 22 | – | – | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 030” | VOLTAGE | – | 5 | 5 | 4 | 2 | 2 | 1 | 1 | – | – |

| 0.8MM | WIRESPEED | – | 50 | 58 | 50 | 30 | 20 | 10 | 0 | – | – |

|

|

|

|

|

|

|

|

|

|

|

| |

.035” | VOLTAGE | 6 | 5 | 4 | 3 | 2 | 2 | 1 | 1 | – | – | |

FLUXCORE | 0.9MM | WIRESPEED | 50 | 40 | 38 | 30 | 20 | 10 | 0 | 0 | – | – |

| .045” | VOLTAGE | 5 | 5 | 4 | 3 | 2 | 2 | – | – | – | – |

| 1.2MM | WIRESPEED | 46 | 40 | 30 | 20 | 0 | 0 | – | – | – | – |

|

|

|

|

|

|

|

|

|

|

|

|

|

.035” | VOLTAGE | 7 | 7 | 7 | 6 | 5 | 3 | – | – | – | – | |

FLUXCORE | 0.9MM | WIRESPEED | 80 | 78 | 72 | 68 | 60 | 55 | – | – | – | – |

75AR/25CO2 |

|

|

|

|

|

|

|

|

|

|

|

|

.045” | VOLTAGE | 7 | 7 | 7 | 6 | 5 | 4 | – | – | – | – | |

20CFH | 1.2MM | WIRESPEED | 70 | 65 | 60 | 50 | 42 | 36 | – | – | – | – |

ER308L | .023” | VOLTAGE | – | – | – | 5 | 4 | 3 | 3 | 2 | – | – |

STAINLESS | 0.6MM | WIRESPEED | – | – | – | 100 | 80 | 60 | 52 | 22 | – | – |

90% HE |

|

|

|

|

|

|

|

|

|

|

|

|

.030” | VOLTAGE | – | – | 6 | 5 | 4 | 3 | 3 | 2 | – | – | |

7.5% AR | 0.8MM | WIRESPEED | – | – | 90 | 72 | 60 | 38 | 30 | 18 | – | – |

2.5% CO2 | .035” | VOLTAGE | 7 | 6 | 5 | 4 | 4 | 3 | 2 | 2 | – | – |

20CFH | 0.9MM | WIRESPEED | 75 | 70 | 70 | 64 | 62 | 35 | 20 | 14 | – | – |

*Do not change Voltage switch position while welding. Wire Speed is a starting value only, and can be adjusted while welding. Weld conditions also depend on other variables such as stickout, travel speed, weld angle, cleanliness of metal, etc.