|

| GSA |

|

| |

|

| |

❏ Check monthly | ❏ Check monthly | |

Boiler relief valve

1. After following the warning directions below, if the relief valve weeps or will

not seat properly, replace the relief valve.

Before testing, make certain discharge pipe is properly

connected to valve outlet and arranged to

contain and safely dispose of boiler discharge. Wear gloves to protect your

hands from hot surfaces. Verify that

discharge piping is installed in accordance with this manual and the instructions on the relief valve tag. Failure to comply will expose operator and others to severe personal injury or death.

![]() Safety relief valves should be reinspected AT LEAST ONCE EVERY THREE YEARS, by a licensed plumbing contractor or authorized inspection agency, to ensure that

Safety relief valves should be reinspected AT LEAST ONCE EVERY THREE YEARS, by a licensed plumbing contractor or authorized inspection agency, to ensure that

the product has not been affected by corrosive water conditions and to ensure that the valve and discharge line have not been altered or tampered with illegally. Certain naturally occurring conditions may corrode the valve or its components over time, rendering the valve inoperative. Such conditions are not detectable unless the valve and its components are physically removed and inspected. This inspection must only be conducted by a plumbing contractor or authorized inspection agency — not by the owner. Failure to reinspect the boiler relief valve as directed could result in unsafe pressure buildup, which can result in severe personal injury, death or substantial property damage.

Check the setting of the boiler limit control.The control should never be set with a pressure above

10 psig. Operating at a higher pressure can cause damage to the boiler relief valve.

The boiler relief valve must be tested at least monthly during the heating season to verify the valve

and discharge piping flow freely. If corrosion and/or deposits are noticed within the valve body, testing must be performed more often. A “try lever test” must also be performed at the end of any non- service period. Follow the instructions below for a “try lever test”.

•With the system at operating pressure, lift and hold the test lever fully open for at least 5 seconds to flush the valve seat free of sediment and debris.Then release lever and permit the valve to snap shut.

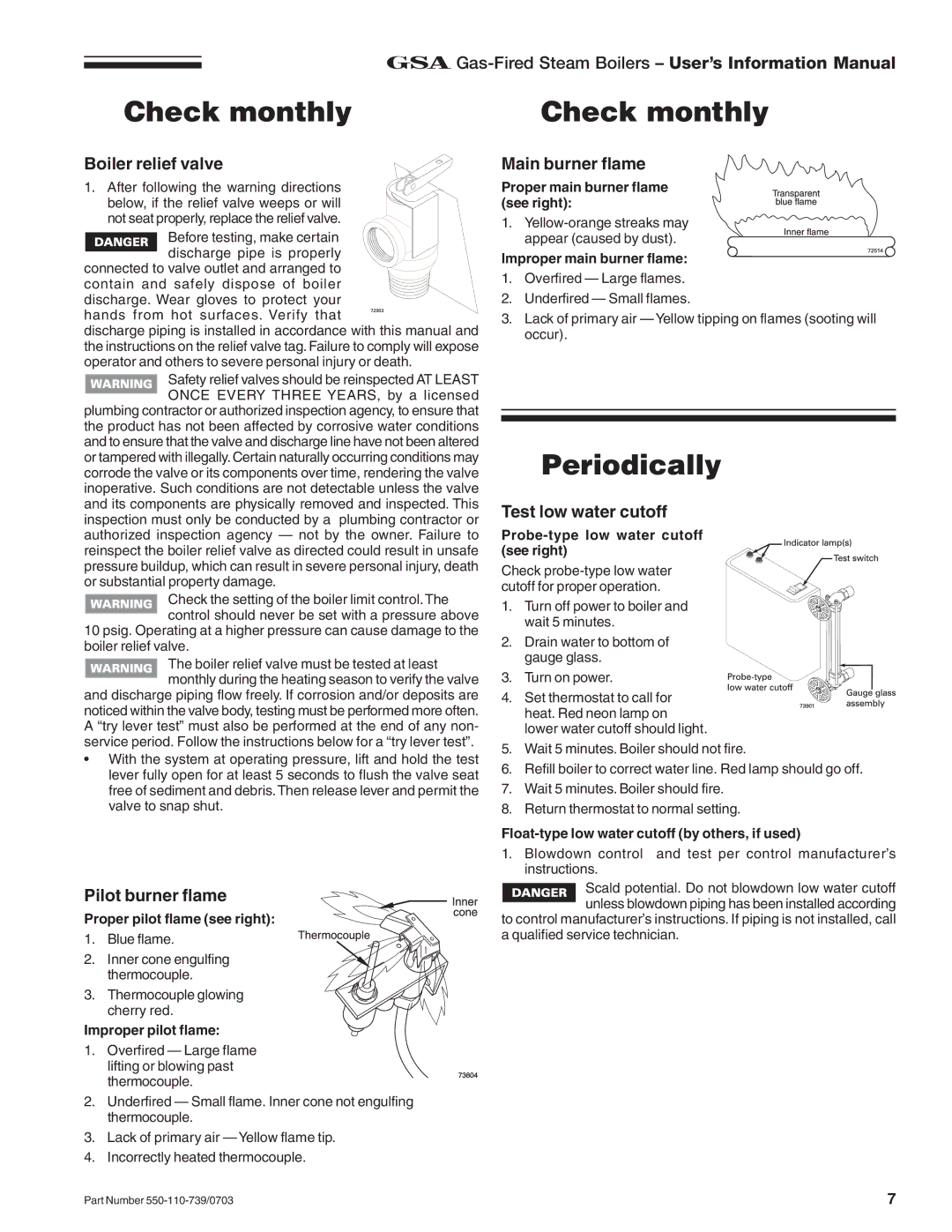

Pilot burner flame

Proper pilot flame (see right):

1. Blue flame.

2. Inner cone engulfing thermocouple.

3. Thermocouple glowing cherry red.

Improper pilot flame:

1.Overfired — Large flame lifting or blowing past thermocouple.

2.Underfired — Small flame. Inner cone not engulfing thermocouple.

3.Lack of primary air — Yellow flame tip.

4.Incorrectly heated thermocouple.

Main burner flame

Proper main burner flame (see right):

1.

Improper main burner flame:

1.Overfired — Large flames.

2.Underfired — Small flames.

3.Lack of primary air — Yellow tipping on flames (sooting will occur).

❏Periodically

Test low water cutoff

Probe-type low water cutoff (see right)

Check

1. Turn off power to boiler and wait 5 minutes.

2.Drain water to bottom of gauge glass.

3. Turn on power.

4. Set thermostat to call for heat. Red neon lamp on lower water cutoff should light.

5.Wait 5 minutes. Boiler should not fire.

6.Refill boiler to correct water line. Red lamp should go off.

7.Wait 5 minutes. Boiler should fire.

8.Return thermostat to normal setting.

Float-type low water cutoff (by others, if used)

1.Blowdown control and test per control manufacturer’s instructions.

![]() Scald potential. Do not blowdown low water cutoff unless blowdown piping has been installed according to control manufacturer’s instructions. If piping is not installed, call

Scald potential. Do not blowdown low water cutoff unless blowdown piping has been installed according to control manufacturer’s instructions. If piping is not installed, call

a qualified service technician.

Part Number | 7 |