Chart Environmental Chambers | Features |

Features

❏Temperature Control System:

Heating is accomplished with resistive electric elements, while cooling is accomplished by blowing liquid nitrogen into the chamber. The liquid nitrogen is vaporized through nozzles and the cold vapor is circulated over the products in the chamber so that liquid nitrogen does not touch the product under test. Electric heaters are carefully selected and arranged to provide extremely rapid rates of temperature change without exceeding safe design limits of heat elements. The heaters and nitrogen nozzles are located in the air conditioning plenum.

CAUTION: Although the chamber is designed to use very small amounts of liquid nitrogen, the resulting nitrogen gas is vented out of the chamber. It is important to monitor the oxygen levels in the working environment around the chamber to ensure safe operating conditions.

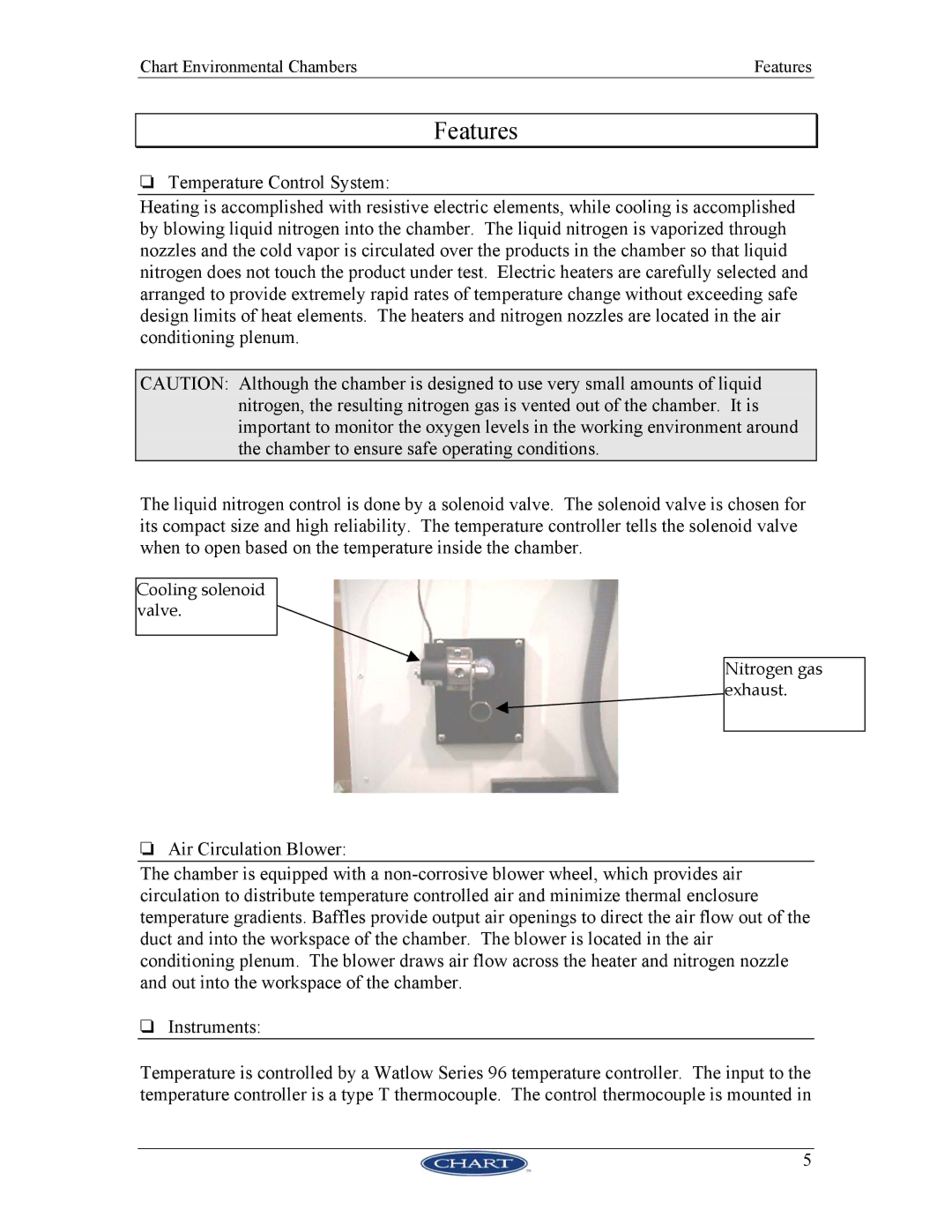

The liquid nitrogen control is done by a solenoid valve. The solenoid valve is chosen for its compact size and high reliability. The temperature controller tells the solenoid valve when to open based on the temperature inside the chamber.

Cooling solenoid valve.

Nitrogen gas exhaust.

❏Air Circulation Blower:

The chamber is equipped with a

❑Instruments:

Temperature is controlled by a Watlow Series 96 temperature controller. The input to the temperature controller is a type T thermocouple. The control thermocouple is mounted in

5