Service

Follow the Service Notes in Figs. 8 and 9 when ![]()

![]() reassembling the gun.

reassembling the gun.

Gun repair kits are available. See page 18. Refer- ence numbers marked with an asterisk (*) in the service procedures are included with the 288171 Air Seal Repair Kit. Reference numbers marked with a symbol (†) in the service procedures are included with the 288137 Fluid Repair Kit.

Disassembly

1.Follow Pressure Relief Procedure, page 11.

2.Unscrew the four screws (14) and remove the gun from the manifold.

3.Unscrew the tip retainer nut (7). Remove the spray tip (9) and gasket (8). See Figs. 8 and 9.

4.Remove the cap (18) from the piston housing (1). Remove the springs (20 and 19).

5.Using the supplied wrench (34), loosen the fluid needle setscrew (16). Remove the needle stop (17).

6.Remove the seat (10, 41).

CAUTION

Be sure to keep the needle straight when removing it from the gun. If the needle is bent it must be replaced.

7.Pull the needle assembly (12) straight out the front of the gun. Remove the

8.Remove the gasket (11).

CAUTION

Install a new gasket (11) whenever you remove the seat (10, 41) from the gun. Failure to install a new gasket may result in fluid leaking into the air chamber.

Service

9.Remove the piston. Using a pliers, pull the piston (21) out of the piston housing (1).

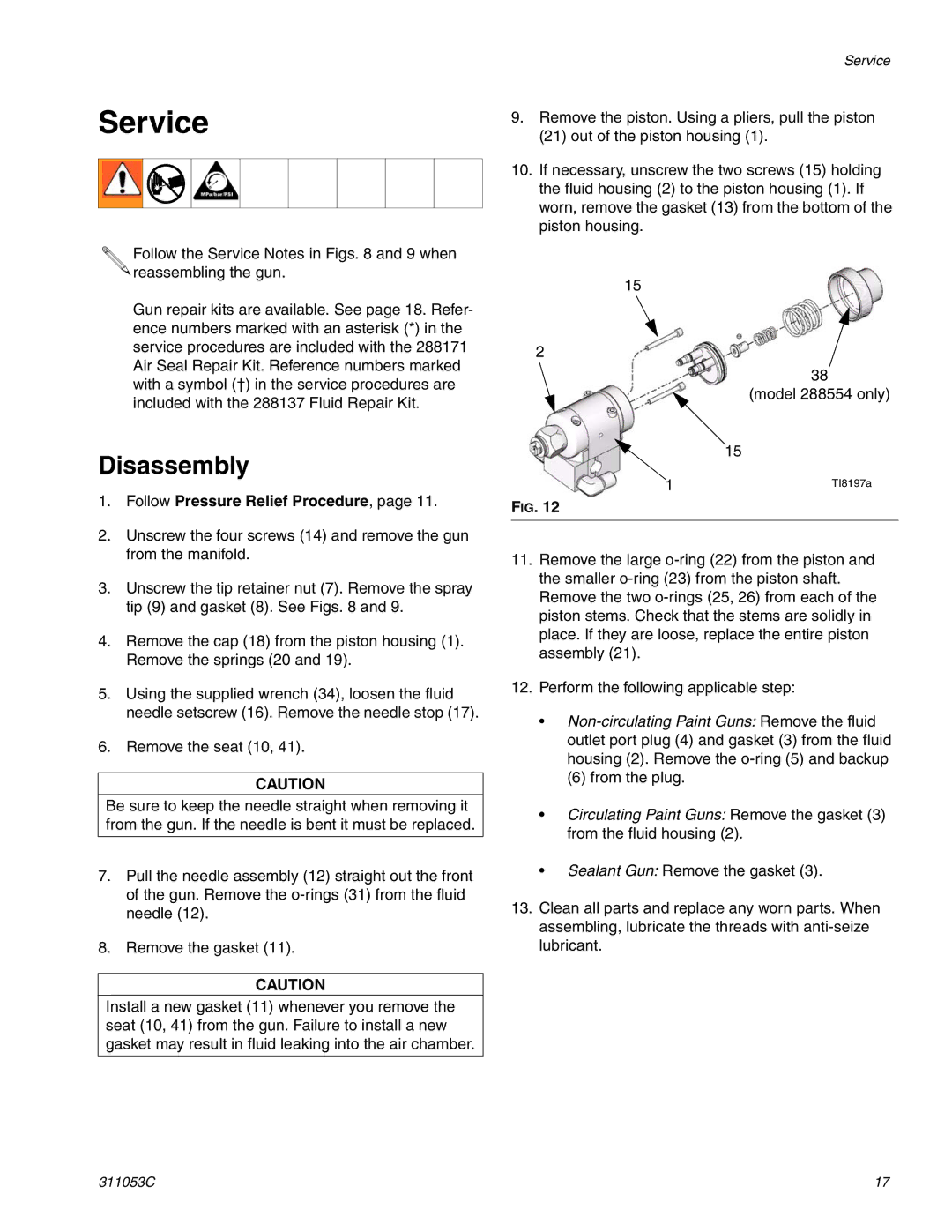

10.If necessary, unscrew the two screws (15) holding the fluid housing (2) to the piston housing (1). If worn, remove the gasket (13) from the bottom of the piston housing.

15

2

38

(model 288554 only)

15

1 | TI8197a |

FIG. 12

11.Remove the large

12.Perform the following applicable step:

•

(6) from the plug.

•Circulating Paint Guns: Remove the gasket (3) from the fluid housing (2).

•Sealant Gun: Remove the gasket (3).

13.Clean all parts and replace any worn parts. When assembling, lubricate the threads with

311053C | 17 |