CABLING

CABLING

RapidRun™ Connector Technology

Flexibility.

The secret to RapidRun’'D5s flexibility is its

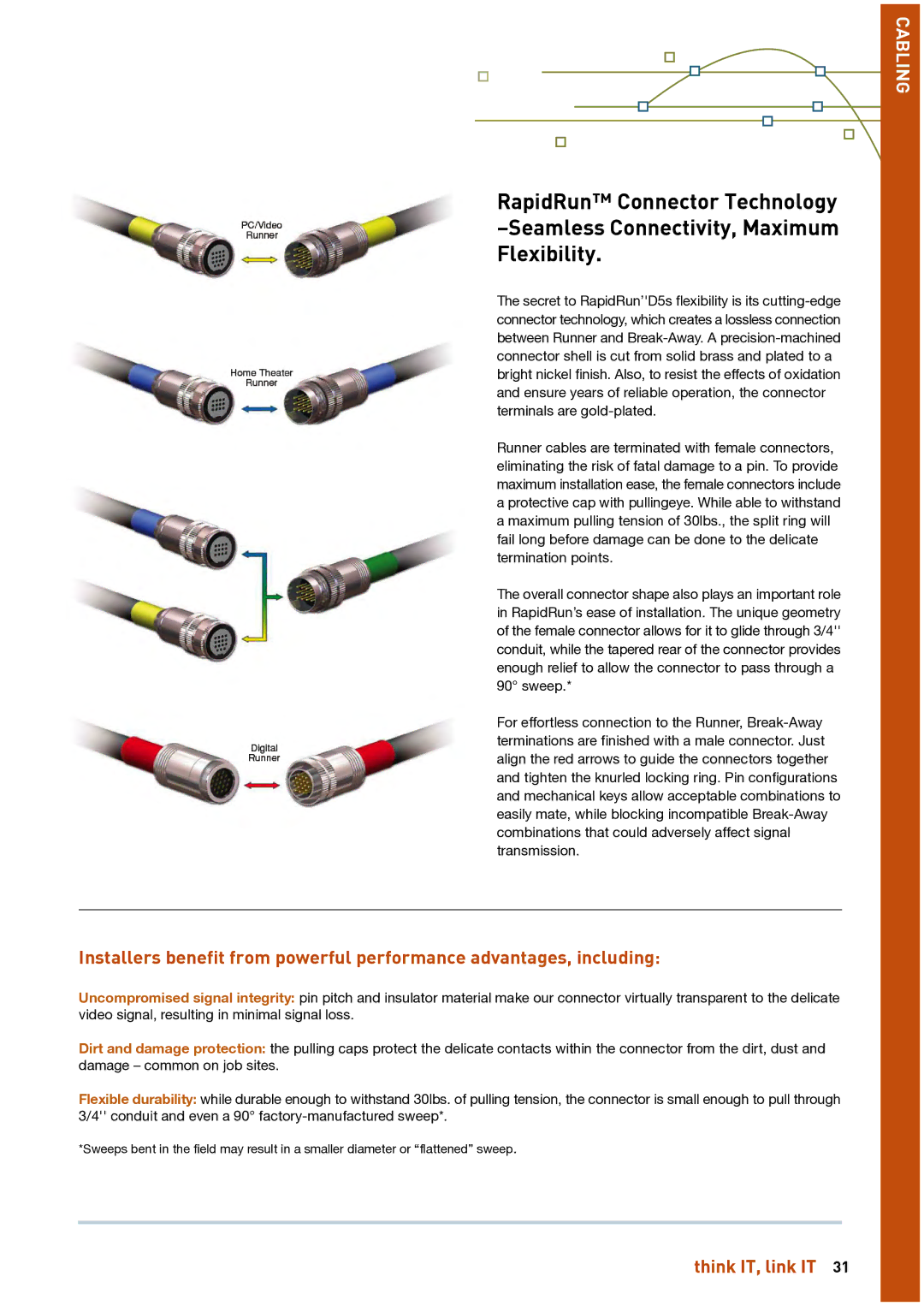

Runner cables are terminated with female connectors, eliminating the risk of fatal damage to a pin. To provide maximum installation ease, the female connectors include a protective cap with pullingeye. While able to withstand a maximum pulling tension of 30lbs., the split ring will fail long before damage can be done to the delicate termination points.

The overall connector shape also plays an important role in RapidRun’s ease of installation. The unique geometry of the female connector allows for it to glide through 3/4'' conduit, while the tapered rear of the connector provides enough relief to allow the connector to pass through a 90° sweep.*

For effortless connection to the Runner,

Installers benefit from powerful performance advantages, including:

Uncompromised signal integrity: pin pitch and insulator material make our connector virtually transparent to the delicate video signal, resulting in minimal signal loss.

Dirt and damage protection: the pulling caps protect the delicate contacts within the connector from the dirt, dust and damage – common on job sites.

Flexible durability: while durable enough to withstand 30lbs. of pulling tension, the connector is small enough to pull through 3/4'' conduit and even a 90°

*Sweeps bent in the field may result in a smaller diameter or “flattened” sweep.

31