HANGER BALL/

DOWNROD ASSEMBLY

CEILING

COVER

CLEVIS | CLEVIS | |

PIN | PIN | |

SETSCREW | HAIRPIN | |

CLIP | ||

| ||

| SETSCREW | |

MOTOR COUPLING |

|

8.Rotate the motor hub until the flange screw hole is next to the cutout in the switch housing plate. Attach one blade assembly to the motor hub using two M6 x 14 flange screws with lockwashers preassembled in flange. Make sure the screws are NOT tightened. (Figure 3.) Repeat this procedure for the other four blade assemblies.

SWITCH HOUSING | BLADE FLANGE |

PLATE |

|

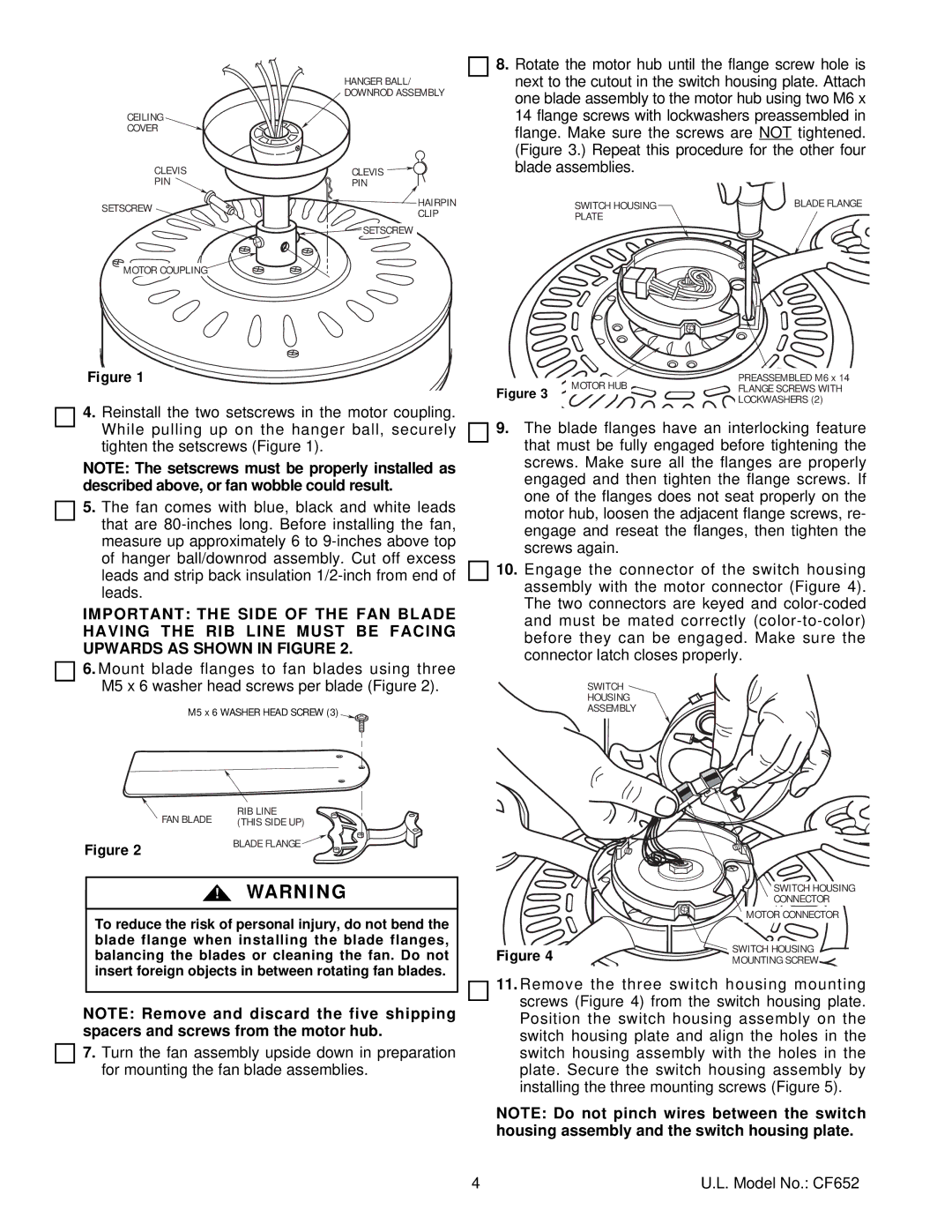

Figure 1

4.Reinstall the two setscrews in the motor coupling. While pulling up on the hanger ball, securely tighten the setscrews (Figure 1).

NOTE: The setscrews must be properly installed as described above, or fan wobble could result.

5.The fan comes with blue, black and white leads that are

IMPORTANT: THE SIDE OF THE FAN BLADE HAVING THE RIB LINE MUST BE FACING UPWARDS AS SHOWN IN FIGURE 2.

6.Mount blade flanges to fan blades using three M5 x 6 washer head screws per blade (Figure 2).

M5 x 6 WASHER HEAD SCREW (3)

WASHER HEAD SCREW (3)

| MOTOR HUB | PREASSEMBLED M6 x 14 |

Figure 3 | FLANGE SCREWS WITH | |

| LOCKWASHERS (2) | |

|

|

9.The blade flanges have an interlocking feature that must be fully engaged before tightening the screws. Make sure all the flanges are properly engaged and then tighten the flange screws. If one of the flanges does not seat properly on the motor hub, loosen the adjacent flange screws, re- engage and reseat the flanges, then tighten the screws again.

10. Engage the connector of the switch housing assembly with the motor connector (Figure 4). The two connectors are keyed and

SWITCH

HOUSING

ASSEMBLY

FAN BLADE | RIB LINE |

(THIS SIDE UP) | |

Figure 2 | BLADE FLANGE |

|

!WARNING

To reduce the risk of personal injury, do not bend the blade flange when installing the blade flanges, balancing the blades or cleaning the fan. Do not insert foreign objects in between rotating fan blades.

NOTE: Remove and discard the five shipping spacers and screws from the motor hub.

7.Turn the fan assembly upside down in preparation for mounting the fan blade assemblies.

| SWITCH HOUSING |

| CONNECTOR |

| MOTOR CONNECTOR |

Figure 4 | SWITCH HOUSING |

MOUNTING SCREW |

11.Remove the three switch housing mounting screws (Figure 4) from the switch housing plate. Position the switch housing assembly on the switch housing plate and align the holes in the switch housing assembly with the holes in the plate. Secure the switch housing assembly by installing the three mounting screws (Figure 5).

NOTE: Do not pinch wires between the switch housing assembly and the switch housing plate.

4 | U.L. Model No.: CF652 |