1/2” Impact Wrench

Llave de Impacto de 13mm

before attempting to install, service,

relocate or perform any maintenance.

14.Keep all nuts, bolts and screws tight and ensure equipment is in safe working condition.

15.Do not put hands near or under moving parts.

Do not misuse this

!WARNING product. Excessive exposure to vibration, work in awkward positions, and repetitive work motions can cause injury to hands and arms. Stop using any tool if discomfort, numbness, tingling, or pain occur, and consult a physician.

Operation

LUBRICATION

Proper lubrication is the owner’s responsibility. Failure to lubricate the air tool properly will dramatically shorten the life of the tool and will

4. Connect the impact wrench to the |

|

| When re- | |||

| ! WARNING | |||||

| air supply and cover the exhaust port |

| assembling be | |||

| with a towel. Run the impact wrench | careful not to overtighten. Bolts may | ||||

| in both the forward and reverse | fail or cause a hazardous condition. Be | ||||

| sure to set the regulator to the | |||||

| directions for 20 to 30 seconds. Oil | |||||

| minimum setting then use a torque | |||||

| will discharge from the exhaust port | |||||

| wrench to set torque. | |||||

| when air pressure is applied. | |||||

| NOTE: It is not recommended to install a | |||||

IMPACT MECHANISM LUBRICATION | ||||||

quick coupler between the tool and the | ||||||

Lubricate the impact mechanism | ||||||

whip hose. |

| |||||

monthly. |

| Using fittings or air hoses which are too | ||||

|

| Disconnect the | ||||

|

| small can create a pressure drop and | ||||

| ! WARNING | |||||

| impact wrench | reduce the power of the tool. For 3/8, | ||||

|

| |||||

from the air supply before lubricating. | ||||||

1/2 and 3/4” impact wrenches use 3/8” | ||||||

1. Disconnect the impact wrench from | ||||||

(I.D.) fittings with 1/4” NPT threads. | ||||||

| the air supply. |

| Most compressors are shipped with a | |||

2. Remove the slotted screw or allen | short, 1/4” I.D. hose. For proper | |||||

| head screw from the oil port hole. | performance and more convenience, | ||||

3. Squeeze approximately 1 oz. of air | use a 3/8” I.D. hose. Hoses longer than | |||||

50 feet should have a 1/2” I.D. | ||||||

| tool oil in the oil port hole. Replace | |||||

|

|

| Never carry a tool | |||

| the screw. |

|

| ! WARNING | ||

|

|

| by the hose or pull | |||

4. Reconnect the air supply to the |

| |||||

the hose to move the tool or a | ||||||

(Con’t)

manguera corta de 6,3mm (1/4”) de diámetro interno. Para un funcionamiento adecuado y para mayor conveniencia, use una manguera de 10mm (3/8”) de diámetro interno. Las mangueras de más de 15,24m (50 pies) de longuitud deben tener un diámetro interno de 13mm (1/2”).

de longuitud deben tener un diámetro interno de 13mm (1/2”).

!ADVERTENCIA Nuncacargue

una herramienta por la manguera o hale la manguera para mover la herramienta o un compresor. Mantenga las mangueras alejadas del calor, aceite o puntas afiladas, reemplace cualquier manguera que esté dañada, deteriorada o desgastada.

Almacenamiento

La llave de impacto se debe lubricar antes de almacenarla. Siga las instrucciones de lubricación excepto el paso 4. Sólo déjela funcionar 2 ó 3 segundos en vez de 20 ó 30 segundos ya que debe almacenar la con más aceite en el mecanismo de impacto.

Servicio Técnico

Para mayor información referente al funcionamiento o reparación de este producto comúniquese con el distribuidor de Campbell Hausfeld más cercano a su domicilio.

Información Sobre Piezas de Repuesto

Para obtener información de como obtener piezas de repuesto en Estados Unidos, sírvase llamar al

Hausfeld más cercano a su domicilio. Suministre la siguiente información:

•Número del modelo

•Código estampado

•Número de pieza y descripción

Puede escribirnos a:

Campbell Hausfeld Attn: Parts Department 100 Production Drive Harrison, Ohio 45030 U.S.A.

void the warranty.

! CAUTION | This impact wrench |

requires lubrication |

BEFORE the initial use and BEFORE and AFTER each additional use.

Impact wrenches require lubrication throughout the life of the tool and must be lubricated in two separate areas: the air motor and the impact mechanism. Air tool oil is recommended because this oil cleans, lubricates and inhibits rust all in one step.

AIR MOTOR LUBRICATION

The motor must be lubricated daily. An air motor cannot be oiled too often.

Disconnect the ! WARNING impact wrench

from the air supply before lubricating.

1. Disconnect the impact wrench from the air supply.

2. Turn the impact wrench upside down.

3. While pulling the trigger, squeeze approximately a 1/4 oz. of airtool oil in the air inlet. Then, push the forward and reverse button in both directions.

After an air tool

! WARNING has been

lubricated, oil will discharge through the exhaust port during the first few seconds of operation. Thus, THE EXHAUST PORT MUST BE COVERED WITH A TOWEL before applying air pressure.

FAILURE TO COVER THE EXHAUST PORT CAN RESULT IN SERIOUS INJURY.

impact wrench and run for 20 to 30 | compressor. Keep hoses away from | |||

seconds. Lubricate the entire impact | heat, oil and sharp edges. Replace any | |||

mechanism by rotating the tool |

| hose that is damaged, weak or worn. | ||

upside down and sideways while |

| Storage |

| |

running the tool. |

|

| ||

5. Remove the screw and hold the oil | The impact wrench must be lubricated | |||

port hole over a suitable container to | before storing. Follow the air motor | |||

allow excess oil to drain. Sometimes | lubrication instructions with an | |||

triggering the tool when dumping | exception to step 4. Only run the | |||

the oils helps to force out the excess | impact wrench for 2 to 3 seconds | |||

oil. |

| instead of 20 to 30 seconds because | ||

6. If the oil is dirty, repeat the |

| more oil needs to remain in the impact | ||

procedure above until the oil comes | wrench when storing. |

| ||

out clear. Install the screw and |

| Technical Service |

| |

tighten. The residual oil remaining in | For information regarding the | |||

the impact mechanism chamber is all | ||||

operation or repair of this product, | ||||

that is needed for proper lubrication. | ||||

please call | ||||

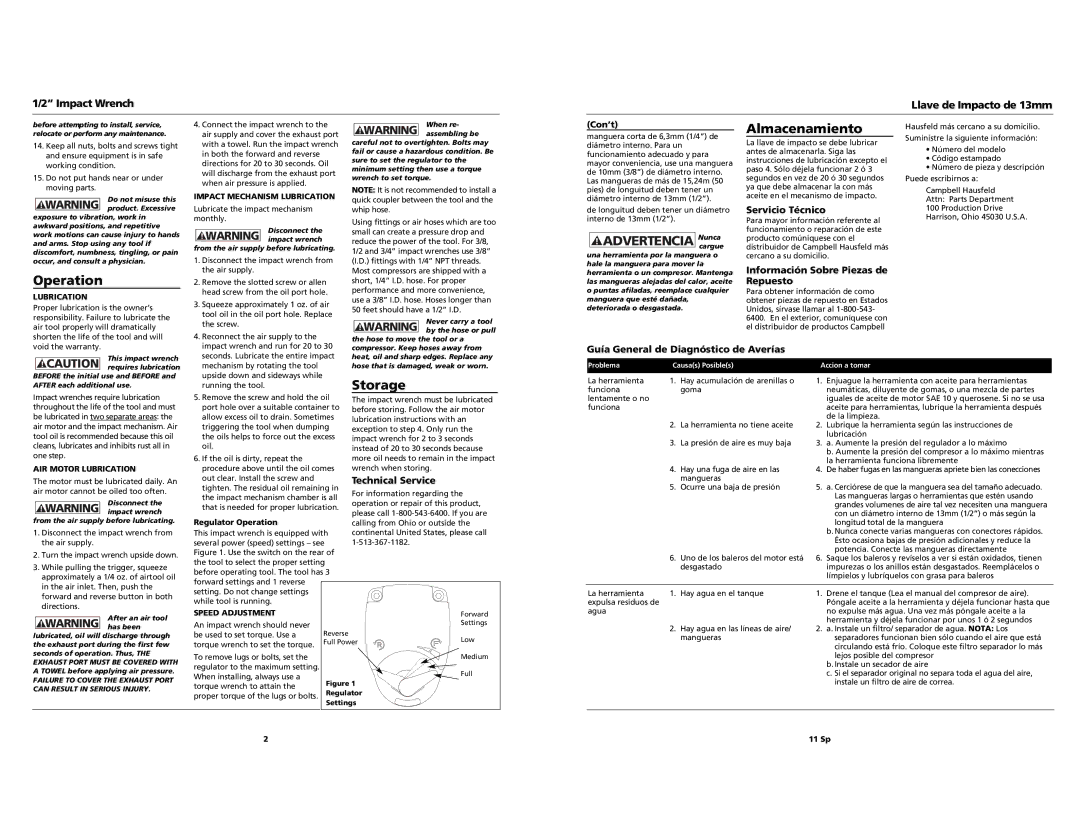

Regulator Operation |

| |||

| calling from Ohio or outside the | |||

This impact wrench is equipped with | continental United States, please call | |||

several power (speed) settings – see |

| |||

Figure 1. Use the switch on the rear of |

|

| ||

the tool to select the proper setting |

|

| ||

before operating tool. The tool has 3 |

|

| ||

forward settings and 1 reverse |

|

|

| |

setting. Do not change settings |

|

|

| |

while tool is running. |

|

|

| |

SPEED ADJUSTMENT |

|

| Forward | |

An impact wrench should never |

|

| Settings | |

Reverse |

|

| ||

be used to set torque. Use a |

| Low | ||

torque wrench to set the torque. | Full Power | |||

| ||||

|

|

| ||

To remove lugs or bolts, set the |

|

| Medium | |

regulator to the maximum setting. |

|

| Full | |

When installing, always use a |

|

| ||

Figure 1 |

| |||

torque wrench to attain the |

| |||

proper torque of the lugs or bolts. Regulator |

| |||

| Settings |

| ||

Guía General de Diagnóstico de Averías

| Problema | Causa(s) Posible(s) | Accion a tomar |

| ||

| La herramienta | 1. | Hay acumulación de arenillas o | 1. | Enjuague la herramienta con aceite para herramientas |

|

| funciona |

| goma |

| neumáticas, diluyente de gomas, o una mezcla de partes |

|

| lentamente o no |

|

|

| iguales de aceite de motor SAE 10 y querosene. Si no se usa |

|

| funciona |

|

|

| aceite para herramientas, lubrique la herramienta después |

|

|

| 2. | La herramienta no tiene aceite |

| de la limpieza. |

|

|

| 2. | Lubrique la herramienta según las instrucciones de |

| ||

|

| 3. | La presión de aire es muy baja |

| lubricación |

|

|

| 3. | a. Aumente la presión del regulador a lo máximo |

| ||

|

|

|

|

| b. Aumente la presión del compresor a lo máximo mientras |

|

|

| 4. | Hay una fuga de aire en las |

| la herramienta funciona libremente |

|

|

| 4. | De haber fugas en las mangueras apriete bien las conecciones |

| ||

|

|

| mangueras |

|

|

|

|

| 5. | Ocurre una baja de presión | 5. | a. Cerciórese de que la manguera sea del tamaño adecuado. |

|

|

|

|

|

| Las mangueras largas o herramientas que estén usando |

|

|

|

|

|

| grandes volumenes de aire tal vez necesiten una manguera |

|

|

|

|

|

| con un diámetro interno de 13mm (1/2”) o más según la |

|

|

|

|

|

| longitud total de la manguera |

|

|

|

|

|

| b. Nunca conecte varias mangueras con conectores rápidos. |

|

|

|

|

|

| Ésto ocasiona bajas de presión adicionales y reduce la |

|

|

|

|

|

| potencia. Conecte las mangueras directamente |

|

|

| 6. | Uno de los baleros del motor está | 6. | Saque los baleros y revíselos a ver si están oxidados, tienen |

|

|

|

| desgastado |

| impurezas o los anillos están desgastados. Reemplácelos o |

|

|

|

|

|

| límpielos y lubríquelos con grasa para baleros |

|

|

|

|

|

|

|

|

| La herramienta | 1. | Hay agua en el tanque | 1. | Drene el tanque (Lea el manual del compresor de aire). |

|

| expulsa residuos de |

|

|

| Póngale aceite a la herramienta y déjela funcionar hasta que |

|

| agua |

|

|

| no expulse más agua. Una vez más póngale aceite a la |

|

|

|

|

|

| herramienta y déjela funcionar por unos 1 ó 2 segundos |

|

|

| 2. | Hay agua en las líneas de aire/ | 2. | a. Instale un filtro/ separador de agua. NOTA: Los |

|

|

|

| mangueras |

| separadores funcionan bien sólo cuando el aire que está |

|

|

|

|

|

| circulando está frío. Coloque este filtro separador lo más |

|

|

|

|

|

| lejos posible del compresor |

|

b. Instale un secador de aire

c. Si el separador original no separa toda el agua del aire, instale un filtro de aire de correa.

2 | 11 Sp |