MAINTENANCE

Lubricating the bar tip sprocket

Lubricate the bar tip sprocket each time you refuel. Use the special grease gun and a good quality bearing grease.

Needle bearing lubrication

Adjustment of the oil pump

(350)

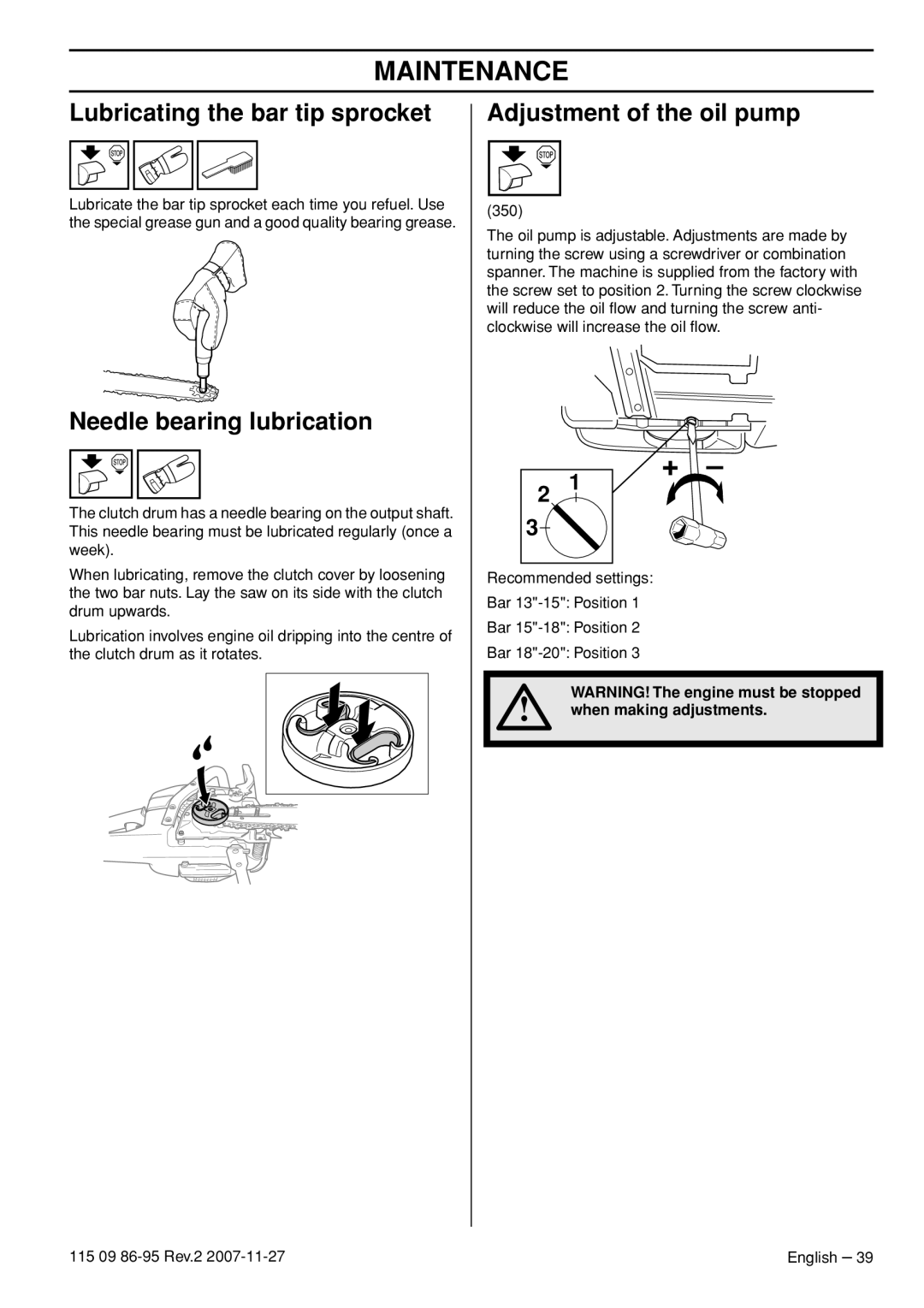

The oil pump is adjustable. Adjustments are made by turning the screw using a screwdriver or combination spanner. The machine is supplied from the factory with the screw set to position 2. Turning the screw clockwise will reduce the oil flow and turning the screw anti- clockwise will increase the oil flow.

The clutch drum has a needle bearing on the output shaft. This needle bearing must be lubricated regularly (once a week).

2 1

3

+ ![]() –

–

When lubricating, remove the clutch cover by loosening the two bar nuts. Lay the saw on its side with the clutch drum upwards.

Lubrication involves engine oil dripping into the centre of the clutch drum as it rotates.

Recommended settings:

Bar

Bar

Bar

| ! | WARNING! The engine must be stopped |

| when making adjustments. | |

|

| |

|

|

|

115 09 | English – 39 |