GENERAL SAFETY PRECAUTIONS

should operate the socket spanner when loosening or tightening the nut.

The nylon lining inside the locking nut must not be so worn that you can turn it by hand. The lining should offer a resistance of at least 1.5 Nm. The nut should be replaced after it has been put on approx. 10 times.

Locking screw

The lock screw must be tightened securely for ball-

Cutting equipment

This section describes how to choose and maintain your cutting equipment in order to:

•Reduce the risk of blade thrust.

•Obtain maximum cutting performance.

•Extend the life of cutting equipment.

IMPORTANT!

Only use cutting attachments with the guards we recommend! See the chapter on Technical data.

Refer to the instructions for the cutting attachment to check the correct way to load the cord and the correct cord diameter.

Keep the teeth of the blade correctly sharpened! Follow our recommendations. Also refer to the instructions on the blade packaging.

Maintain the correct blade setting! Follow our instructions and use the recommended file gauge.

WARNING! Always stop the engine

! before doing any work on the cutting attachment.This continues to rotate even after the throttle has been released. Ensure that the cutting attachment has stopped completely and disconnect the HT lead from the spark plug before you start to work on it.

WARNING! Using an incorrect cutting

! attachment or an incorrectly sharpened blade increases the risk of blade thrust.

Cutting equipment

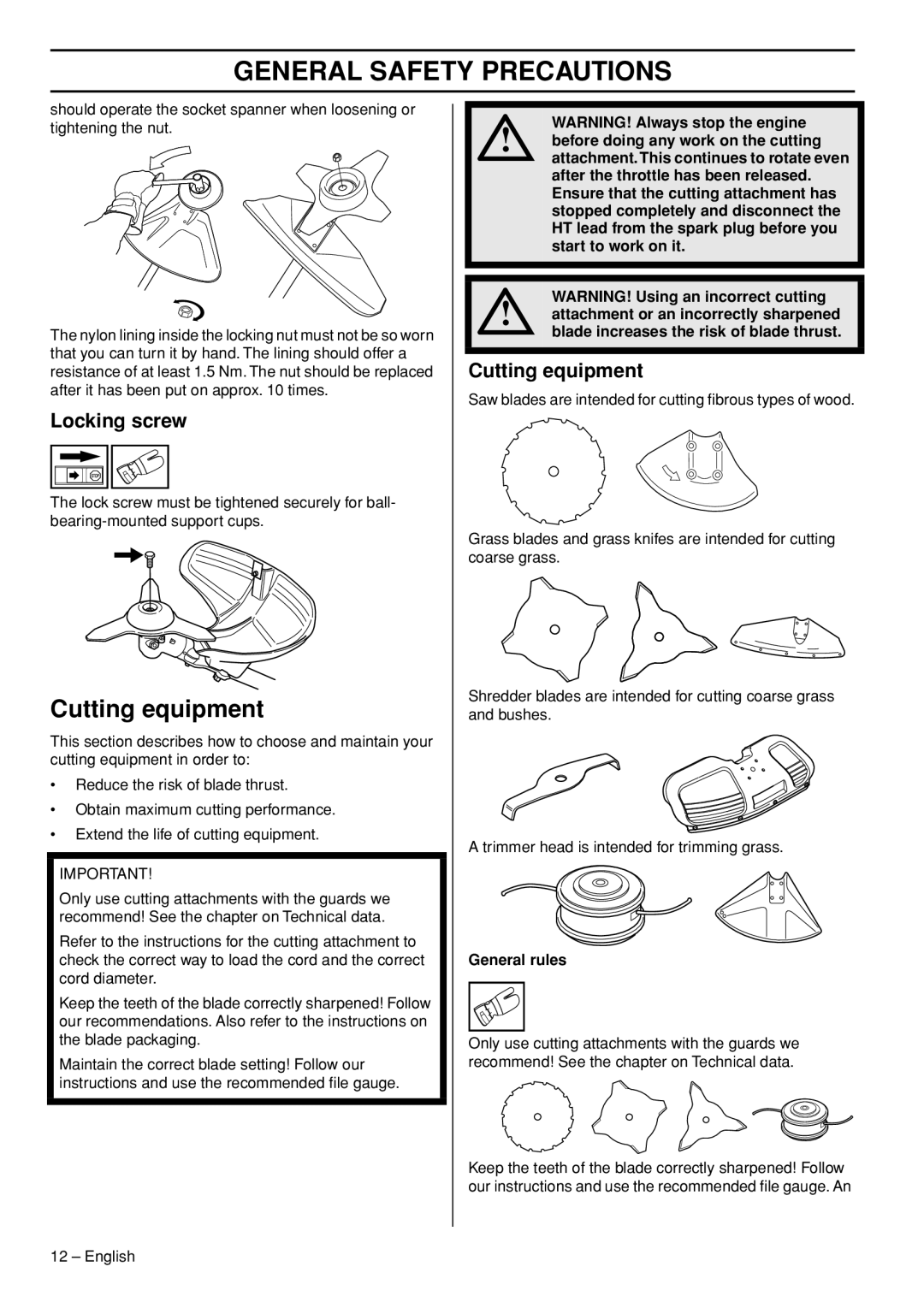

Saw blades are intended for cutting fibrous types of wood.

Grass blades and grass knifes are intended for cutting coarse grass.

Shredder blades are intended for cutting coarse grass and bushes.

A trimmer head is intended for trimming grass.

General rules

Only use cutting attachments with the guards we recommend! See the chapter on Technical data.

Keep the teeth of the blade correctly sharpened! Follow our instructions and use the recommended file gauge. An

12 – English