GENERAL SAFETY PRECAUTIONS

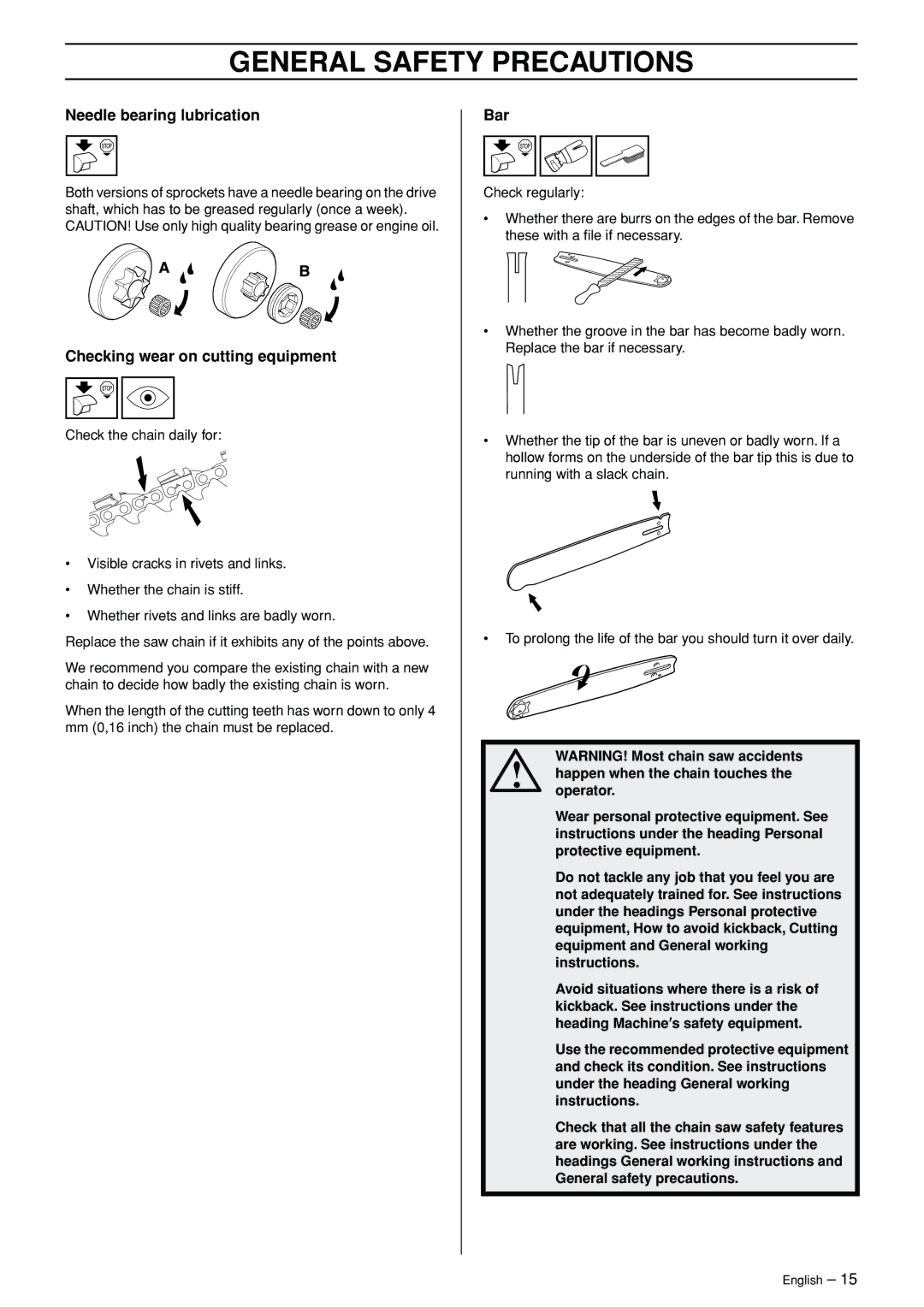

Needle bearing lubrication

Both versions of sprockets have a needle bearing on the drive shaft, which has to be greased regularly (once a week). CAUTION! Use only high quality bearing grease or engine oil.

Checking wear on cutting equipment

Check the chain daily for:

•Visible cracks in rivets and links.

•Whether the chain is stiff.

•Whether rivets and links are badly worn.

Replace the saw chain if it exhibits any of the points above.

We recommend you compare the existing chain with a new chain to decide how badly the existing chain is worn.

When the length of the cutting teeth has worn down to only 4 mm (0,16 inch) the chain must be replaced.

Bar

Check regularly:

•Whether there are burrs on the edges of the bar. Remove these with a file if necessary.

•Whether the groove in the bar has become badly worn. Replace the bar if necessary.

•Whether the tip of the bar is uneven or badly worn. If a hollow forms on the underside of the bar tip this is due to running with a slack chain.

•To prolong the life of the bar you should turn it over daily.

WARNING! Most chain saw accidents

!happen when the chain touches the operator.

Wear personal protective equipment. See instructions under the heading Personal protective equipment.

Do not tackle any job that you feel you are not adequately trained for. See instructions under the headings Personal protective equipment, How to avoid kickback, Cutting equipment and General working instructions.

Avoid situations where there is a risk of kickback. See instructions under the heading Machine′s safety equipment.

Use the recommended protective equipment and check its condition. See instructions under the heading General working instructions.

Check that all the chain saw safety features are working. See instructions under the headings General working instructions and General safety precautions.

English – 15