A

Fig. 2C

•CUTTING ATTACHMENT GUARD

1.Install the cutoff knife as shown below.

2.place the guard on the cutting shaft, then install clamp (A)on the guard. (Fig.3 )

3.Tighten screws (B).

B![]()

![]()

![]()

![]() A

A

GB

•REMOVE AND INSTALLATION THE BLADE COVER

CAUTION: Before you take apart the blades, wear gloves to prevent any danger.

CAUTION: When the machine is not in use or in transportation, make sure blades have been covered.

1.Before assembling blades, please remove the blades cover first.

2.Refer figure 5A and Figure 5B, hold the blades cover, and pull sligtly the cover outward the cover can be taken apart.

3.Refer to figure 5C and 5D, and assemble in the oppo- site way to cover the blades.

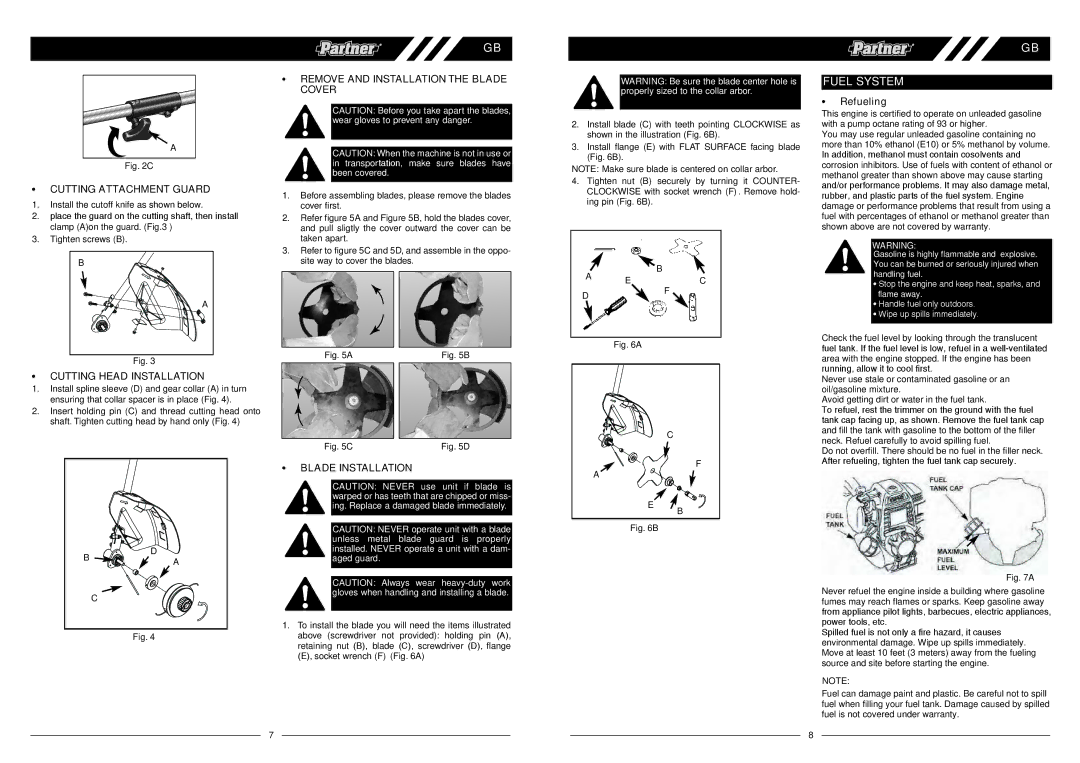

WARNING: Be sure the blade center hole is properly sized to the collar arbor.

2.Install blade (C) with teeth pointing CLOCKWISE as shown in the illustration (Fig. 6B).

3.Install flange (E) with FLAT SURFACE facing blade (Fig. 6B).

NOTE: Make sure blade is centered on collar arbor.

4.Tighten nut (B) securely by turning it COUNTER- CLOCKWISE with socket wrench (F) . Remove hold- ing pin (Fig. 6B).

![]() B

B

A EC

D ![]() F

F ![]()

GB

FUEL SYSTEM

•Refueling

This engine is certified to operate on unleaded gasoline with a pump octane rating of 93 or higher.

You may use regular unleaded gasoline containing no more than 10% ethanol (E10) or 5% methanol by volume. In addition, methanol must contain cosolvents and corrosion inhibitors. Use of fuels with content of ethanol or methanol greater than shown above may cause starting and/or performance problems. It may also damage metal, rubber, and plastic parts of the fuel system. Engine damage or performance problems that result from using a fuel with percentages of ethanol or methanol greater than shown above are not covered by warranty.

WARNING:

Gasoline is highly flammable and explosive. You can be burned or seriously injured when handling fuel.

•Stop the engine and keep heat, sparks, and flame away.

•Handle fuel only outdoors.

•Wipe up spills immediately.

Fig. 3

•CUTTING HEAD INSTALLATION

1.Install spline sleeve (D) and gear collar (A) in turn ensuring that collar spacer is in place (Fig. 4).

2.Insert holding pin (C) and thread cutting head onto shaft. Tighten cutting head by hand only (Fig. 4)

Fig. 5A |

| Fig. 5B |

|

|

|

Fig. 6A

C

Check the fuel level by looking through the translucent fuel tank. If the fuel level is low, refuel in a

Never use stale or contaminated gasoline or an oil/gasoline mixture.

Avoid getting dirt or water in the fuel tank.

To refuel, rest the trimmer on the ground with the fuel tank cap facing up, as shown. Remove the fuel tank cap and fill the tank with gasoline to the bottom of the filler neck. Refuel carefully to avoid spilling fuel.

Do not overfill. There should be no fuel in the filler neck.

•BLADE INSTALLATION

A ![]()

F

After refueling, tighten the fuel tank cap securely.

D

B ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() A

A

C

Fig. 4

CAUTION: NEVER use unit if blade is warped or has teeth that are chipped or miss- ing. Replace a damaged blade immediately.

CAUTION: NEVER operate unit with a blade unless metal blade guard is properly installed. NEVER operate a unit with a dam- aged guard.

CAUTION: Always wear

1.To install the blade you will need the items illustrated above (screwdriver not provided): holding pin (A), retaining nut (B), blade (C), screwdriver (D), flange (E), socket wrench (F) (Fig. 6A)

7

E

B

Fig. 6B

Fig. 7A

Never refuel the engine inside a building where gasoline fumes may reach flames or sparks. Keep gasoline away from appliance pilot lights, barbecues, electric appliances, power tools, etc.

Spilled fuel is not only a fire hazard, it causes environmental damage. Wipe up spills immediately. Move at least 10 feet (3 meters) away from the fueling source and site before starting the engine.

NOTE:

Fuel can damage paint and plastic. Be careful not to spill fuel when filling your fuel tank. Damage caused by spilled fuel is not covered under warranty.

8