ENGINE OIL

The trimmer is shipped WITHOUT OIL in the engine. NOTE:Fill oil before starting engine.

1.Place the trimmer on a level surface, and then remove the oil filler cap/dipstick.

GB

NOTE:

Running the engine with too little or too much oil can cause engine damage.

4.Screw in the oil filler cap/dipstick securely.

•Engine Oil Change

Drain the used oil while the engine is warm. Warm oil drains quickly and completely.

OPERATING INSTRUCTIONS

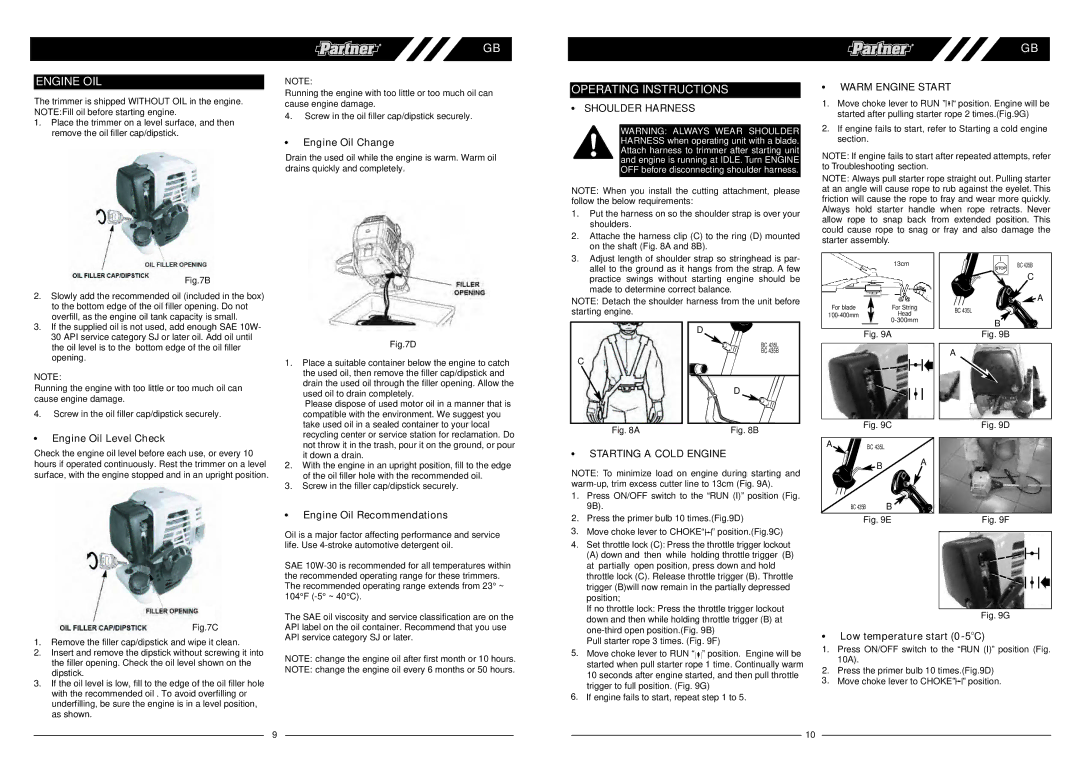

•SHOULDER HARNESS

WARNING: ALWAYS WEAR SHOULDER HARNESS when operating unit with a blade. Attach harness to trimmer after starting unit and engine is running at IDLE. Turn ENGINE OFF before disconnecting shoulder harness.

NOTE: When you install the cutting attachment, please follow the below requirements:

1. | Put the harness on so the shoulder strap is over your |

| shoulders. |

2. | Attache the harness clip (C) to the ring (D) mounted |

| on the shaft (Fig. 8A and 8B). |

3. | Adjust length of shoulder strap so stringhead is par- |

GB

• WARM ENGINE START

1. Move choke lever to RUN ”![]() “ position. Engine will be started after pulling starter rope 2 times.(Fig.9G)

“ position. Engine will be started after pulling starter rope 2 times.(Fig.9G)

2. If engine fails to start, refer to Starting a cold engine section.

NOTE: If engine fails to start after repeated attempts, refer to Troubleshooting section.

NOTE: Always pull starter rope straight out. Pulling starter at an angle will cause rope to rub against the eyelet. This friction will cause the rope to fray and wear more quickly. Always hold starter handle when rope retracts. Never allow rope to snap back from extended position. This could cause rope to snag or fray and also damage the starter assembly.

Fig.7B

2. Slowly add the recommended oil (included in the box) |

to the bottom edge of the oil filler opening. Do not |

overfill, as the engine oil tank capacity is small. |

allel to the ground as it hangs from the strap. A few |

practice swings without starting engine should be |

made to determine correct balance. |

NOTE: Detach the shoulder harness from the unit before starting engine.

|

|

|

|

|

|

|

| 13cm | ||

|

| For blade |

|

|

|

| For String | |||

|

|

|

|

|

| |||||

|

|

|

|

|

| Head | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BC 435B

C

![]() A

A

BC 435L

3. If the supplied oil is not used, add enough SAE 10W- |

30 API service category SJ or later oil. Add oil until |

the oil level is to the bottom edge of the oil filler |

opening. |

NOTE:

Running the engine with too little or too much oil can cause engine damage.

4.Screw in the oil filler cap/dipstick securely.

•Engine Oil Level Check

Fig.7D

1. Place a suitable container below the engine to catch |

the used oil, then remove the filler cap/dipstick and |

drain the used oil through the filler opening. Allow the |

used oil to drain completely. |

Please dispose of used motor oil in a manner that is |

compatible with the environment. We suggest you |

take used oil in a sealed container to your local |

recycling center or service station for reclamation. Do |

not throw it in the trash, pour it on the ground, or pour |

C

Fig. 8A

D |

BC 435L |

BC 435B |

D |

Fig. 8B |

|

Fig. 9A

Fig. 9C

B![]()

Fig. 9B

A

Fig. 9D

Check the engine oil level before each use, or every 10 hours if operated continuously. Rest the trimmer on a level surface, with the engine stopped and in an upright position.

| it down a drain. |

2. | With the engine in an upright position, fill to the edge |

| of the oil filler hole with the recommended oil. |

3. | Screw in the filler cap/dipstick securely. |

•Engine Oil Recommendations

Oil is a major factor affecting performance and service life. Use

SAE

The SAE oil viscosity and service classification are on the

•STARTING A COLD ENGINE

NOTE: To minimize load on engine during starting and

1.Press ON/OFF switch to the “RUN (I)” position (Fig. 9B).

2.Press the primer bulb 10 times.(Fig.9D)

3.Move choke lever to CHOKE“![]() ” position.(Fig.9C)

” position.(Fig.9C)

4.Set throttle lock (C): Press the throttle trigger lockout

(A) down and then while holding throttle trigger (B)

at partially open position, press down and hold throttle lock (C). Release throttle trigger (B). Throttle trigger (B)will now remain in the partially depressed position;

If no throttle lock: Press the throttle trigger lockout down and then while holding throttle trigger (B) at

![]() B A

B A

BC 435B | B |

Fig. 9E

Fig. 9G

Fig. 9F

Fig. 9G

Fig.7C

1.Remove the filler cap/dipstick and wipe it clean.

2.Insert and remove the dipstick without screwing it into the filler opening. Check the oil level shown on the dipstick.

3.If the oil level is low, fill to the edge of the oil filler hole with the recommended oil . To avoid overfilling or underfilling, be sure the engine is in a level position, as shown.

9

API label on the oil container. Recommend that you use API service category SJ or later.

NOTE: change the engine oil after first month or 10 hours.

NOTE: change the engine oil every 6 months or 50 hours.

5.Move choke lever to RUN “![]() ” position. Engine will be started when pull starter rope 1 time. Continually warm 10 seconds after engine started, and then pull throttle trigger to full position. (Fig. 9G)

” position. Engine will be started when pull starter rope 1 time. Continually warm 10 seconds after engine started, and then pull throttle trigger to full position. (Fig. 9G)

6.If engine fails to start, repeat step 1 to 5.

10

•Low temperature start (0-5OC)

1.Press ON/OFF switch to the “RUN (I)” position (Fig. 10A).

2.Press the primer bulb 10 times.(Fig.9D)

3.Move choke lever to CHOKE”![]() ” position.

” position.