K950 specifications

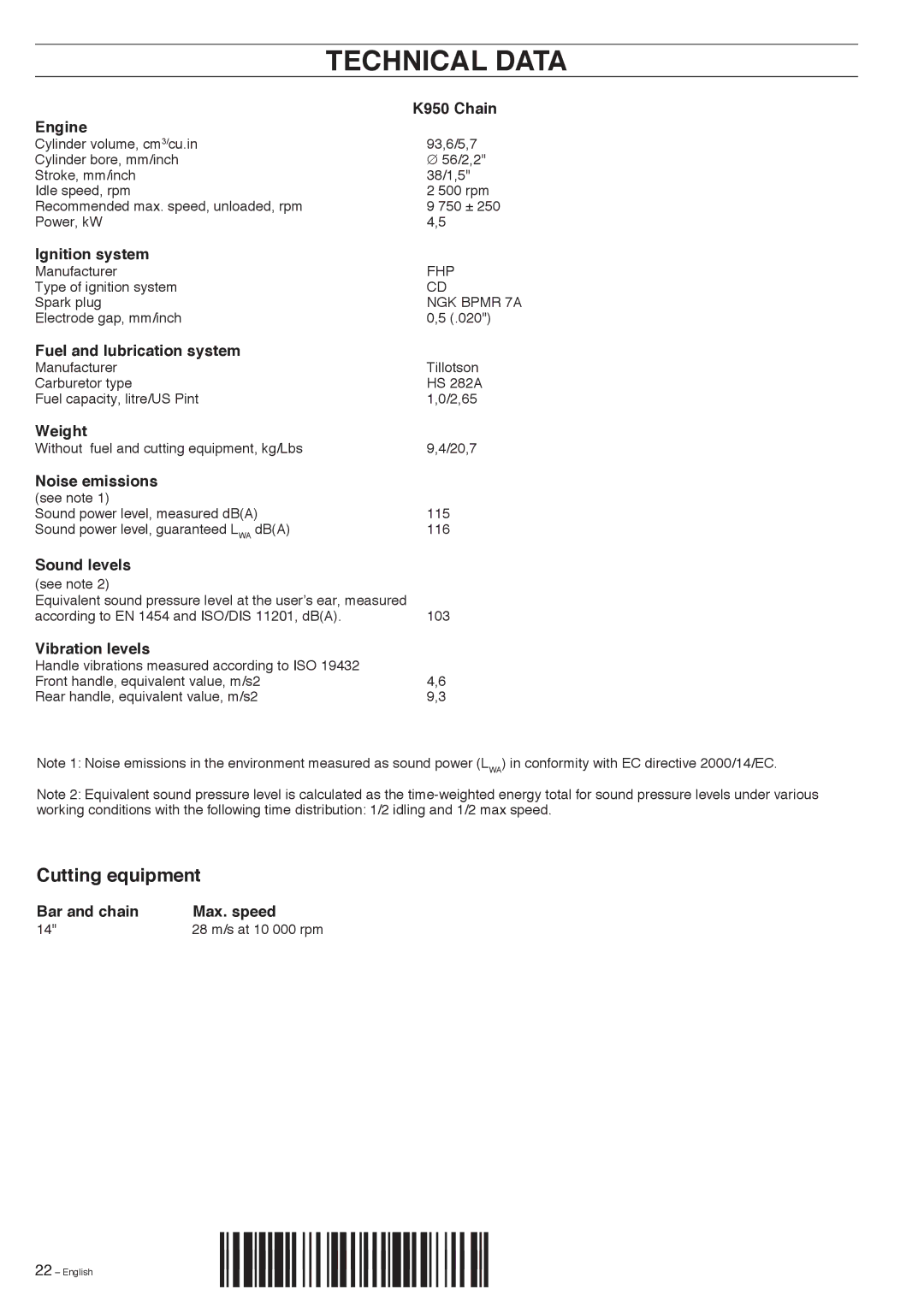

The Husqvarna K950 is a robust and powerful concrete cutter designed particularly for professionals who demand high performance in heavy-duty tasks. Renowned for its precision and durability, the K950 has set a standard in the construction and demolition industries.One of the standout features of the K950 is its engine. Powered by a reliable 2-stroke, air-cooled engine, it delivers impressive performance with a displacement of 93.6 cc. This engine provides the necessary torque and power for cutting through various materials including concrete, asphalt, and masonry effortlessly. A two-stage filtration system ensures the engine remains clean and operates efficiently, extending its service life and reducing maintenance demands.

A key technology integrated into the K950 is the SmartPower system. This innovation optimizes the engine’s power output while reducing fuel consumption and emissions, making it environmentally friendly without compromising on performance. The K950 also features a vibration dampening system connected to the handle, which significantly reduces operator fatigue during prolonged use. This ergonomic design enables greater control and comfort, enhancing safety and efficiency.

The adjustable blade guard allows for easy modifications to the cutting depth and angle, facilitating versatile usage in different applications. Operators can use blades ranging up to 14 inches in diameter, accommodating a variety of cutting requirements. This flexibility makes the K950 suitable for both small renovations and large construction projects.

The K950’s lightweight yet sturdy design increases its maneuverability on the job site. Weighing approximately 24.4 kg, it is easy to transport and handle while providing the robustness needed for rigorous cutting tasks. The easy-to-reach controls and simplified starting mechanism help ensure operational efficiency even in demanding environments.

In terms of maintenance, Husqvarna has designed the K950 for easy servicing. Its accessible components allow operators to perform routine checks and repairs with minimal downtime.

Overall, the Husqvarna K950 blends power, precision, and advanced technology, making it a top choice for professionals in the field looking for a reliable cutting tool to enhance their productivity and efficiency on any job site. Whether tackling concrete paving, road construction, or demolition tasks, the K950 stands out as a dependable and high-performing solution.