SAFETY INSTRUCTIONS

•Special care should be taken with abrasive discs. Abrasive discs must be stored on a flat, level surface. If an abrasive disc is stored in humid conditions, this can cause imbalance and result in injury.

•Inspect new blades for transport or storage damage.

Fuel safety

(Refuelling/Fuel mixture/Storage.)

WARNING! Take care when handling fuel.

!Bear in mind the risk of fire, explosion and inhaling fumes.

•Never refuel the machine while the engine is running.

•Make sure there is plenty of ventilation when refuelling or mixing fuel (gasoline and

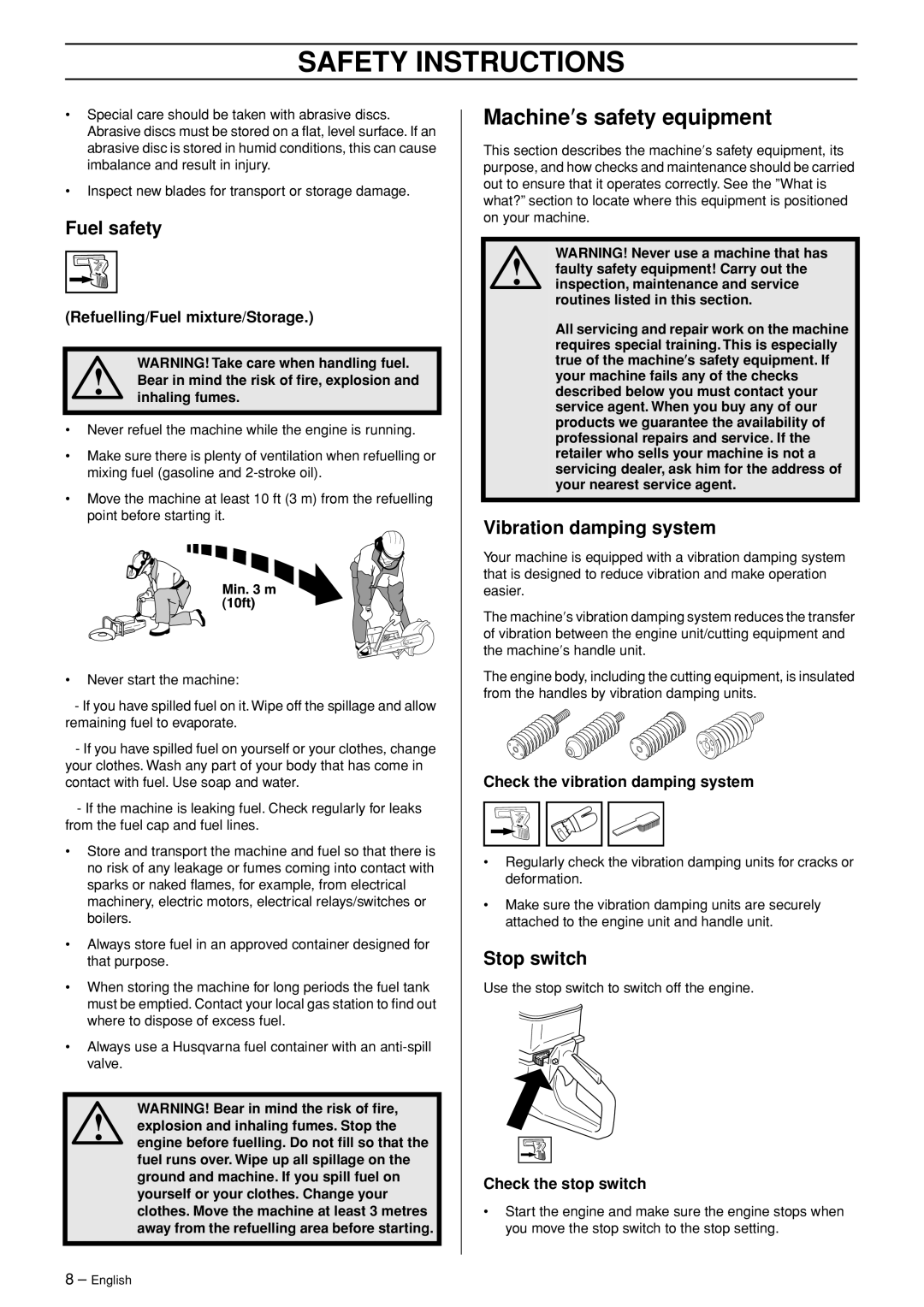

•Move the machine at least 10 ft (3 m) from the refuelling point before starting it.

•Never start the machine:

-If you have spilled fuel on it. Wipe off the spillage and allow remaining fuel to evaporate.

-If you have spilled fuel on yourself or your clothes, change your clothes. Wash any part of your body that has come in contact with fuel. Use soap and water.

-If the machine is leaking fuel. Check regularly for leaks from the fuel cap and fuel lines.

•Store and transport the machine and fuel so that there is no risk of any leakage or fumes coming into contact with sparks or naked flames, for example, from electrical machinery, electric motors, electrical relays/switches or boilers.

•Always store fuel in an approved container designed for that purpose.

•When storing the machine for long periods the fuel tank must be emptied. Contact your local gas station to find out where to dispose of excess fuel.

•Always use a Husqvarna fuel container with an

WARNING! Bear in mind the risk of fire,

!explosion and inhaling fumes. Stop the engine before fuelling. Do not fill so that the fuel runs over. Wipe up all spillage on the ground and machine. If you spill fuel on yourself or your clothes. Change your clothes. Move the machine at least 3 metres away from the refuelling area before starting.

Machine′s safety equipment

This section describes the machine′s safety equipment, its purpose, and how checks and maintenance should be carried out to ensure that it operates correctly. See the ”What is what?” section to locate where this equipment is positioned on your machine.

WARNING! Never use a machine that has

!faulty safety equipment! Carry out the inspection, maintenance and service routines listed in this section.

All servicing and repair work on the machine

requires special training. This is especially true of the machine′s safety equipment. If your machine fails any of the checks described below you must contact your service agent. When you buy any of our products we guarantee the availability of professional repairs and service. If the retailer who sells your machine is not a servicing dealer, ask him for the address of your nearest service agent.

Vibration damping system

Your machine is equipped with a vibration damping system that is designed to reduce vibration and make operation easier.

The machine′s vibration damping system reduces the transfer of vibration between the engine unit/cutting equipment and the machine′s handle unit.

The engine body, including the cutting equipment, is insulated from the handles by vibration damping units.

Check the vibration damping system

•Regularly check the vibration damping units for cracks or deformation.

•Make sure the vibration damping units are securely attached to the engine unit and handle unit.

Stop switch

Use the stop switch to switch off the engine.

Check the stop switch

•Start the engine and make sure the engine stops when you move the stop switch to the stop setting.

8 – English