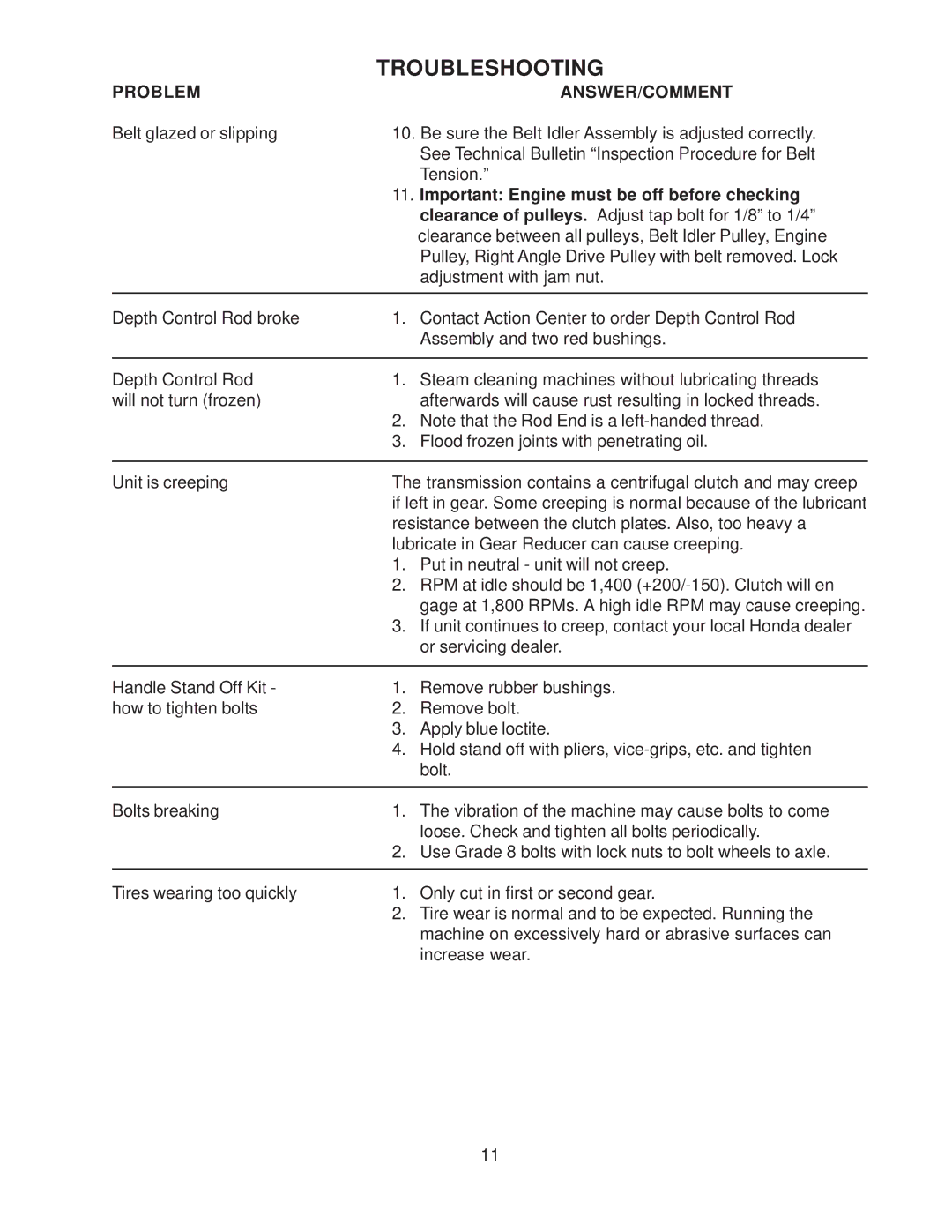

| TROUBLESHOOTING | |

PROBLEM |

| ANSWER/COMMENT |

Belt glazed or slipping | 10. Be sure the Belt Idler Assembly is adjusted correctly. | |

|

| See Technical Bulletin “Inspection Procedure for Belt |

|

| Tension.” |

| 11. Important: Engine must be off before checking | |

|

| clearance of pulleys. Adjust tap bolt for 1/8” to 1/4” |

|

| clearance between all pulleys, Belt Idler Pulley, Engine |

|

| Pulley, Right Angle Drive Pulley with belt removed. Lock |

|

| adjustment with jam nut. |

|

|

|

Depth Control Rod broke | 1. | Contact Action Center to order Depth Control Rod |

|

| Assembly and two red bushings. |

|

|

|

Depth Control Rod | 1. | Steam cleaning machines without lubricating threads |

will not turn (frozen) |

| afterwards will cause rust resulting in locked threads. |

| 2. | Note that the Rod End is a |

| 3. | Flood frozen joints with penetrating oil. |

|

| |

Unit is creeping | The transmission contains a centrifugal clutch and may creep | |

| if left in gear. Some creeping is normal because of the lubricant | |

| resistance between the clutch plates. Also, too heavy a | |

| lubricate in Gear Reducer can cause creeping. | |

| 1. | Put in neutral - unit will not creep. |

| 2. | RPM at idle should be 1,400 |

|

| gage at 1,800 RPMs. A high idle RPM may cause creeping. |

| 3. | If unit continues to creep, contact your local Honda dealer |

|

| or servicing dealer. |

|

|

|

Handle Stand Off Kit - | 1. | Remove rubber bushings. |

how to tighten bolts | 2. | Remove bolt. |

| 3. | Apply blue loctite. |

| 4. | Hold stand off with pliers, |

|

| bolt. |

|

|

|

Bolts breaking | 1. | The vibration of the machine may cause bolts to come |

|

| loose. Check and tighten all bolts periodically. |

| 2. | Use Grade 8 bolts with lock nuts to bolt wheels to axle. |

|

|

|

Tires wearing too quickly | 1. | Only cut in first or second gear. |

| 2. | Tire wear is normal and to be expected. Running the |

|

| machine on excessively hard or abrasive surfaces can |

|

| increase wear. |

11