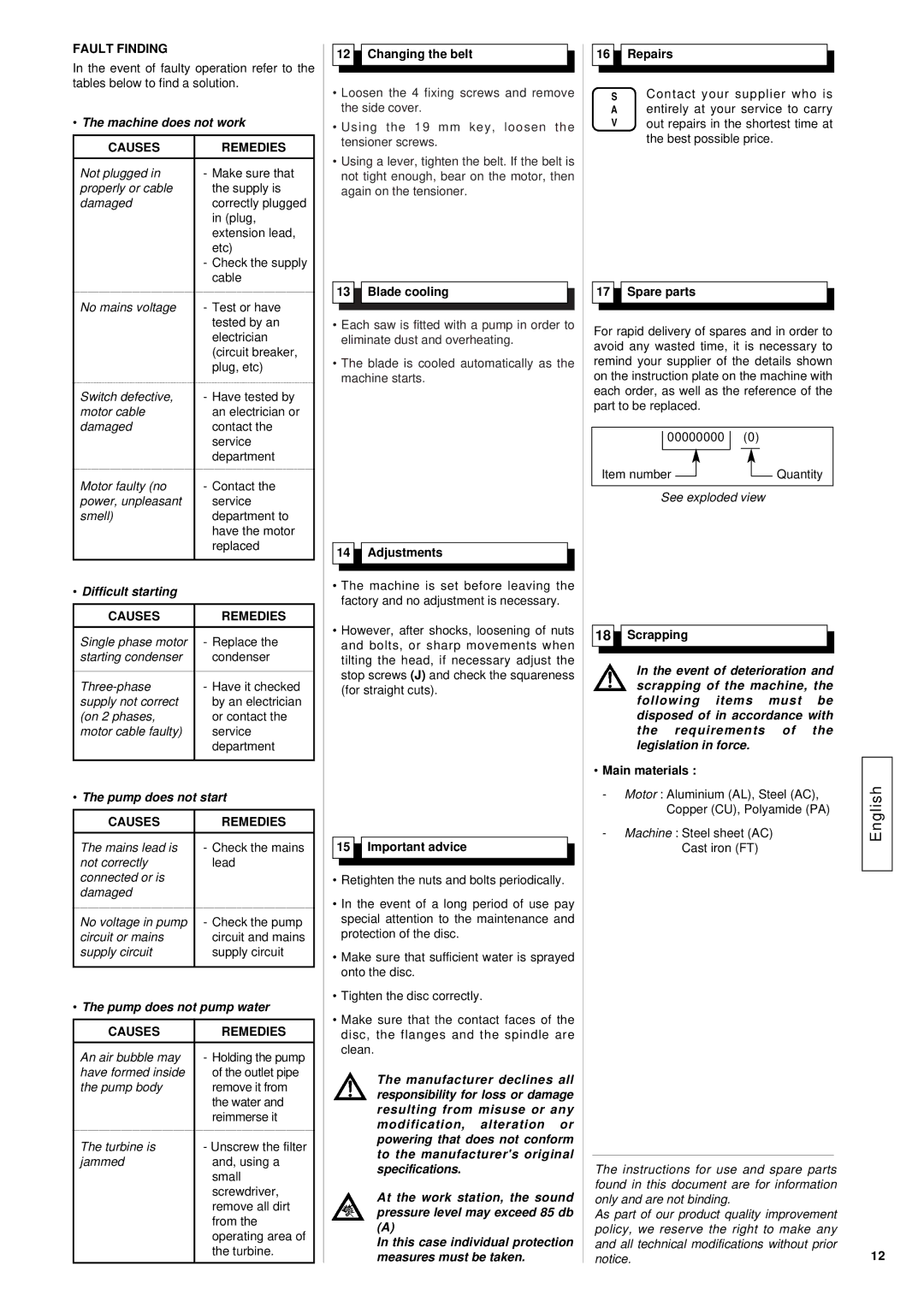

FAULT FINDING

In the event of faulty operation refer to the tables below to find a solution.

• The machine does not work

CAUSES | REMEDIES |

|

|

Not plugged in | - Make sure that |

properly or cable | the supply is |

damaged | correctly plugged |

| in (plug, |

| extension lead, |

| etc) |

| - Check the supply |

| cable |

No mains voltage | - Test or have |

| tested by an |

| electrician |

| (circuit breaker, |

| plug, etc) |

Switch defective, | - Have tested by |

motor cable | an electrician or |

damaged | contact the |

| service |

| department |

Motor faulty (no | - Contact the |

power, unpleasant | service |

smell) | department to |

| have the motor |

| replaced |

|

|

• Difficult starting |

|

|

|

CAUSES | REMEDIES |

|

|

Single phase motor | - Replace the |

starting condenser | condenser |

- Have it checked | |

supply not correct | by an electrician |

(on 2 phases, | or contact the |

motor cable faulty) | service |

| department |

|

|

• The pump does not start |

|

|

|

CAUSES | REMEDIES |

|

|

The mains lead is | - Check the mains |

not correctly | lead |

connected or is |

|

damaged |

|

No voltage in pump | - Check the pump |

circuit or mains | circuit and mains |

supply circuit | supply circuit |

|

|

• The pump does not pump water |

|

|

|

CAUSES | REMEDIES |

|

|

An air bubble may | - Holding the pump |

have formed inside | of the outlet pipe |

the pump body | remove it from |

| the water and |

| reimmerse it |

The turbine is | - Unscrew the filter |

jammed | and, using a |

| small |

| screwdriver, |

| remove all dirt |

| from the |

| operating area of |

| the turbine. |

|

|

12

Changing the belt

Changing the belt

•Loosen the 4 fixing screws and remove the side cover.

•Using the 19 mm key, loosen the tensioner screws.

•Using a lever, tighten the belt. If the belt is not tight enough, bear on the motor, then again on the tensioner.

13

Blade cooling

Blade cooling

•Each saw is fitted with a pump in order to eliminate dust and overheating.

•The blade is cooled automatically as the machine starts.

14

Adjustments

Adjustments

•The machine is set before leaving the factory and no adjustment is necessary.

•However, after shocks, loosening of nuts and bolts, or sharp movements when tilting the head, if necessary adjust the

stop screws (J) and check the squareness (for straight cuts).

15

Important advice

Important advice

•Retighten the nuts and bolts periodically.

•In the event of a long period of use pay special attention to the maintenance and protection of the disc.

•Make sure that sufficient water is sprayed onto the disc.

•Tighten the disc correctly.

•Make sure that the contact faces of the disc, the flanges and the spindle are clean.

The manufacturer declines all responsibility for loss or damage resulting from misuse or any modification, alteration or powering that does not conform

to the manufacturer's original specifications.

At the work station, the sound pressure level may exceed 85 db

(A)

In this case individual protection measures must be taken.

16

Repairs

Repairs

SContact your supplier who is

A entirely at your service to carry

V out repairs in the shortest time at the best possible price.

17

Spare parts

Spare parts

For rapid delivery of spares and in order to avoid any wasted time, it is necessary to remind your supplier of the details shown on the instruction plate on the machine with each order, as well as the reference of the part to be replaced.

00000000 (0)

Item number |

|

| Quantity |

|

|

See exploded view

| 18 |

| Scrapping |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| In the event of deterioration and |

|

|

|

| |

|

|

| scrapping of the machine, the |

|

|

|

| |

|

|

| following items | must | be |

|

| |

|

|

| disposed of in accordance with |

|

|

|

| |

|

|

| the requirements | of | the |

|

| |

|

|

| legislation in force. |

|

|

|

|

|

• Main materials : |

|

|

|

|

| |||

|

|

|

|

| ||||

| - Motor : Aluminium (AL), Steel (AC), |

| English | |||||

|

|

| Motor : Copper (CU), Polyamide (PA) |

| ||||

|

|

|

|

| ||||

| - Machine : Steel sheet (AC) |

|

|

|

| |||

| - Machine :Cast iron (FT) |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

The instructions for use and spare parts |

|

found in this document are for information |

|

only and are not binding. |

|

As part of our product quality improvement |

|

policy, we reserve the right to make any |

|

and all technical modifications without prior | 12 |

notice. |