OPERATOR’S MANUAL | 650295 |

| ||

|

|

|

| |

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE | RELEASED: | |||

| ALSO INCLUDE MANUALS: | (REV. A) IPP | ||

|

|

| ||

| 6” AIR MOTOR | 650295 |

|

|

| 23:1 RATIO | CARBON STEEL |

|

|

| PUMP SYSTEM |

|

| |

| 6” STROKE |

|

| |

|

|

|

|

|

|

|

|

|

|

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

SERVICE KITS

•Use only genuine ARO replacement parts to assure compatible pressure rating and longest service life.

•61355 for repair of Air Motor Section.

•

GENERAL DESCRIPTION

![]()

![]() WARNING DO NOT EXCEED MAXIMUM OPERATING PRESSURE OF 4,215 P.S.I. (294 BAR) AT 150 P.S.I. (10.4 BAR)

WARNING DO NOT EXCEED MAXIMUM OPERATING PRESSURE OF 4,215 P.S.I. (294 BAR) AT 150 P.S.I. (10.4 BAR)

AIR INLET PRESSURE.

![]()

![]() WARNING REFER TO GENERAL INFORMATION SHEET FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPOR% TANT INFORMATION.

WARNING REFER TO GENERAL INFORMATION SHEET FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPOR% TANT INFORMATION.

By delivering a smooth, continuous bead of the proper size, an ARO system helps the operator maintain both his production rate and pro0 duce quality standards. Maintained quality standards assures that the material benefits are realized. To further maximize operator production time, the ARO System has a

ARO Systems are totally enclosed, sealing the material in the system from air and moisture, preventing premature

The 23:1 ratio is an expression of the relationship between the effec0 tive air motor area and the effective lower pump area. When 150 PSI (10 bar) of air pressure is supplied to the air motor, the lower pump area will develop a maximum of 4,215 PSI (294 bar) of fluid pressure (at no flow) as the fluid control is opened, the flow rate will increase as the air motor cycle rate increases to keep up with the demand.

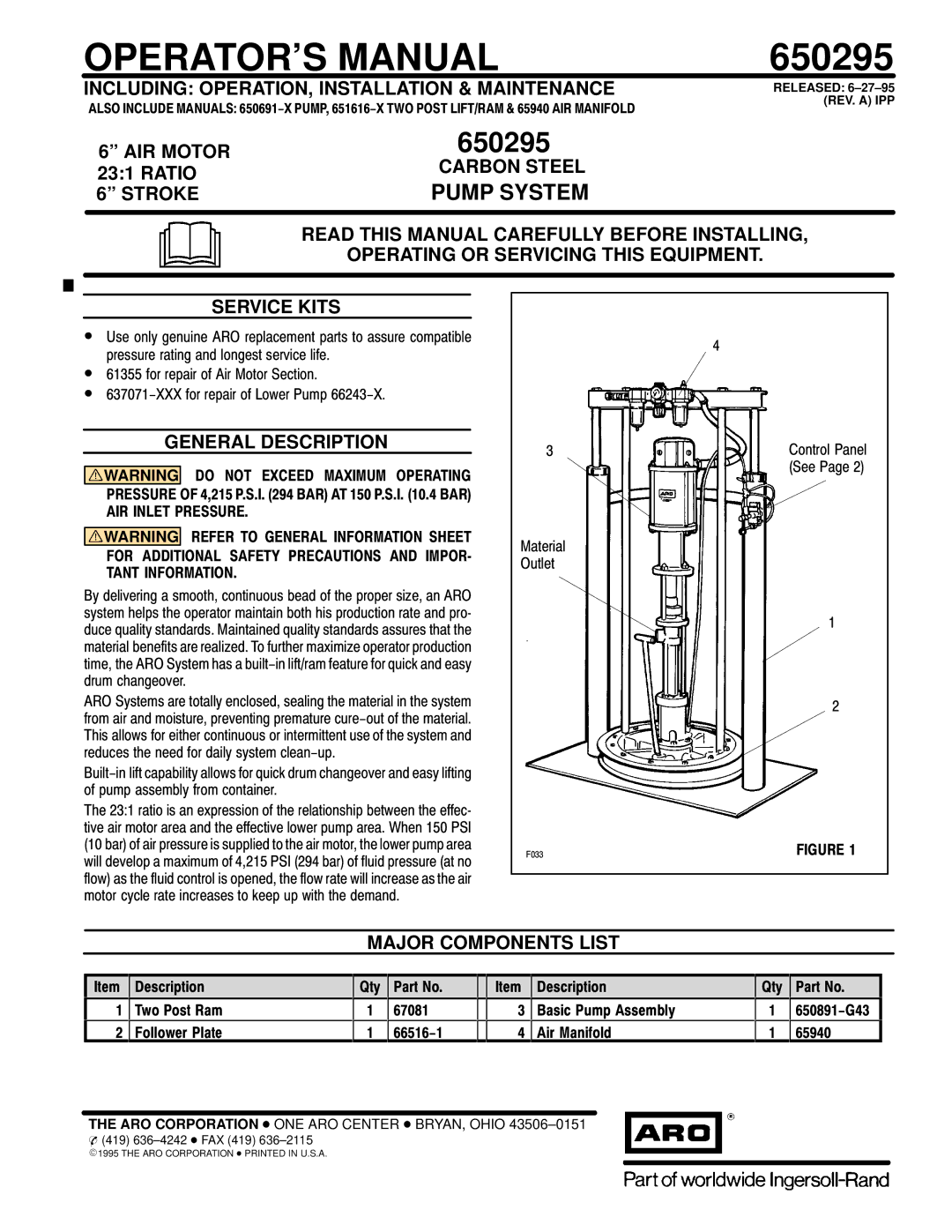

4

3 | Control Panel |

| (See Page 2) |

Material

Outlet

1

2

F033 | FIGURE 1 |

MAJOR COMPONENTS LIST

Item | Description | Qty | Part No. |

| Item | Description | Qty | Part No. |

1 | Two Post Ram | 1 | 67081 |

| 3 | Basic Pump Assembly | 1 | |

2 | Follower Plate | 1 |

| 4 | Air Manifold | 1 | 65940 |

THE ARO CORPORATION D ONE ARO CENTER D BRYAN, OHIO

&(419)

E1995 THE ARO CORPORATION D PRINTED IN U.S.A.