OPERATOR’S MANUAL |

|

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

1” DIAPHRAGM PUMP

1:1 RATIO (NON-METALLIC)

RELEASED:

REVISED:

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to “Model Description Chart” to match the pump material options.

PUMP DATA

Models . . | . . | see Model Description Chart for | |

Pump Type | . . | . | |

Material . . | . | . see Model Description Chart | |

Weight | 20.25 lbs (9.19 kgs) | ||

.20.25 lbs (9.19 kgs) | |||

28.5 lbs (12.93 kgs) | |||

. 28.8 lbs (13.06 kgs | |||

.28.8 lbs (13.06 kgs) | |||

37 lbs (16.78 kgs) | |||

Maximum Air Inlet Pressure | . . 120 p.s.i. (8.3 bar) | ||

Maximum Material Inlet Pressure. . . | . . . 10 p.s.i. (0.69 bar) | ||

| |

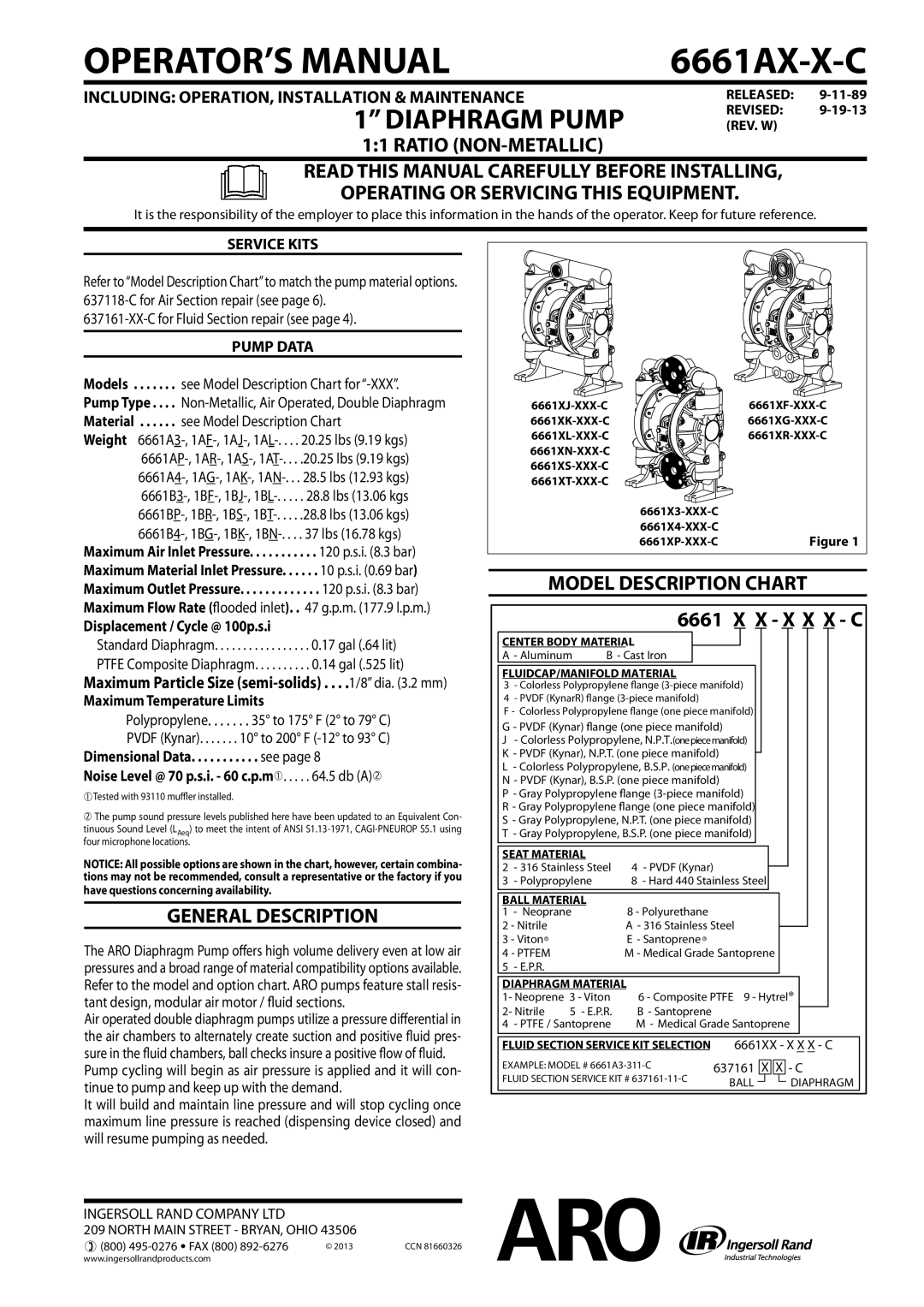

Figure 1 | |

Maximum Outlet Pressure | . . . | 120 p.s.i. (8.3 bar) |

Maximum Flow Rate (flooded inlet). . | 47 g.p.m. (177.9 l.p.m.) | |

Displacement / Cycle @ 100p.s.i |

|

|

Standard Diaphragm | . . 0.17 gal (.64 lit) | |

PTFE Composite Diaphragm | . . 0.14 gal (.525 lit) | |

Maximum Particle Size | . . . .1/8” dia. (3.2 mm) | |

Maximum Temperature Limits |

|

|

Polypropylene. . . . . . . 35° to 175° F (2° to 79° C)

PVDF (Kynar). . . . . . . 10° to 200° F

Dimensional Data. . . . . . . . . . . see page 8

Noise Level @ 70 p.s.i. - 60 c.p.m. . . . . 64.5 db (A)

Tested with 93110 muffler installed.

The pump sound pressure levels published here have been updated to an Equivalent Con- tinuous Sound Level (LAeq) to meet the intent of ANSI

NOTICE: All possible options are shown in the chart, however, certain combina- tions may not be recommended, consult a representative or the factory if you have questions concerning availability.

GENERAL DESCRIPTION

The ARO Diaphragm Pump offers high volume delivery even at low air pressures and a broad range of material compatibility options available. Refer to the model and option chart. ARO pumps feature stall resis- tant design, modular air motor / fluid sections.

Air operated double diaphragm pumps utilize a pressure differential in the air chambers to alternately create suction and positive fluid pres- sure in the fluid chambers, ball checks insure a positive flow of fluid.

Pump cycling will begin as air pressure is applied and it will con- tinue to pump and keep up with the demand.

It will build and maintain line pressure and will stop cycling once maximum line pressure is reached (dispensing device closed) and will resume pumping as needed.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET - BRYAN, OHIO 43506

(800) | © 2013 | CCN 81660326 |

MODEL DESCRIPTION CHART

6661 X X - X X X - C

CENTER BODY MATERIAL

A - Aluminum | B - Cast Iron |

FLUIDCAP/MANIFOLD MATERIAL

3- Colorless Polypropylene flange

4 - PVDF (KynarR) flange

F - Colorless Polypropylene flange (one piece manifold)

G - PVDF (Kynar) flange (one piece manifold)

J- Colorless Polypropylene, N.P.T.(onepiecemanifold) K - PVDF (Kynar), N.P.T. (one piece manifold)

L - Colorless Polypropylene, B.S.P. (onepiecemanifold) N - PVDF (Kynar), B.S.P. (one piece manifold)

P - Gray Polypropylene flange

| SEAT MATERIAL |

|

|

|

|

|

|

|

|

|

|

| ||

2 |

| - 316 Stainless Steel | 4 - PVDF (Kynar) |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |||||

3 |

| - Polypropylene | 8 - Hard 440 Stainless Steel |

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |||

BALL MATERIAL |

|

|

|

|

|

|

|

|

|

|

| |||

1 | - Neoprane | 8 - Polyurethane |

|

|

|

|

|

|

|

|

|

| ||

2 | - Nitrile |

| A - 316 Stainless Steel |

|

|

|

|

|

| |||||

|

|

|

|

|

|

| ||||||||

3 - Viton R |

| E - Santoprene R |

|

|

|

|

|

|

|

|

|

| ||

4 | - PTFEM |

| M - Medical Grade Santoprene |

|

|

|

|

|

| |||||

5 | - E.P.R. |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIAPHRAGM MATERIAL |

|

|

|

|

|

|

|

|

|

| ||||

1- Neoprene 3 - Viton | 6 - Composite PTFE 9 - Hytrel® |

|

| |||||||||||

2- Nitrile | 5 - E.P.R. | B - Santoprene |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| |||||

4 | - PTFE / Santoprene | M - Medical Grade Santoprene |

|

| ||||||||||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

| |||||||||

FLUID SECTION SERVICE KIT SELECTION | 6661XX - X X X - C | |||||||||||||

EXAMPLE: MODEL # | 637161 X X | - C | ||||||||||||

FLUID SECTION SERVICE KIT # |

|

|

|

|

|

|

|

|

|

| ||||

BALL |

| DIAPHRAGM | ||||||||||||

|

|

|

|

|

| |||||||||

www.ingersollrandproducts.com