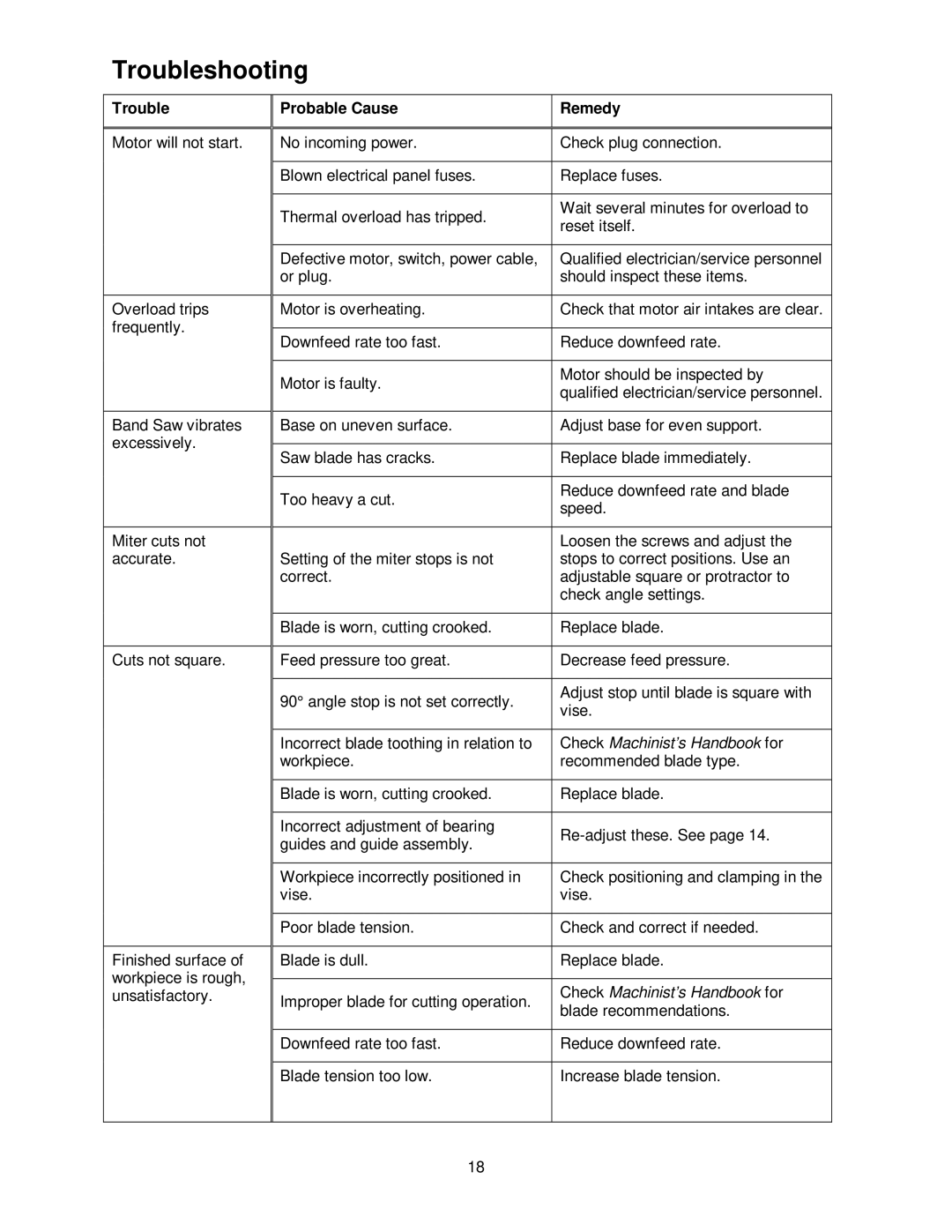

Troubleshooting

Trouble

Motor will not start.

Overload trips frequently.

Band Saw vibrates excessively.

Miter cuts not accurate.

Cuts not square.

Finished surface of workpiece is rough, unsatisfactory.

Probable Cause | Remedy | |

|

| |

No incoming power. | Check plug connection. | |

|

| |

Blown electrical panel fuses. | Replace fuses. | |

|

| |

Thermal overload has tripped. | Wait several minutes for overload to | |

reset itself. | ||

| ||

|

| |

Defective motor, switch, power cable, | Qualified electrician/service personnel | |

or plug. | should inspect these items. | |

|

| |

Motor is overheating. | Check that motor air intakes are clear. | |

|

| |

Downfeed rate too fast. | Reduce downfeed rate. | |

|

| |

Motor is faulty. | Motor should be inspected by | |

qualified electrician/service personnel. | ||

| ||

|

| |

Base on uneven surface. | Adjust base for even support. | |

|

| |

Saw blade has cracks. | Replace blade immediately. | |

|

| |

Too heavy a cut. | Reduce downfeed rate and blade | |

speed. | ||

| ||

|

| |

| Loosen the screws and adjust the | |

Setting of the miter stops is not | stops to correct positions. Use an | |

correct. | adjustable square or protractor to | |

| check angle settings. | |

|

| |

Blade is worn, cutting crooked. | Replace blade. | |

|

| |

Feed pressure too great. | Decrease feed pressure. | |

|

| |

90° angle stop is not set correctly. | Adjust stop until blade is square with | |

vise. | ||

| ||

|

| |

Incorrect blade toothing in relation to | Check Machinist’s Handbook for | |

workpiece. | recommended blade type. | |

|

| |

Blade is worn, cutting crooked. | Replace blade. | |

|

| |

Incorrect adjustment of bearing | ||

guides and guide assembly. | ||

| ||

|

| |

Workpiece incorrectly positioned in | Check positioning and clamping in the | |

vise. | vise. | |

|

| |

Poor blade tension. | Check and correct if needed. | |

|

| |

Blade is dull. | Replace blade. | |

|

| |

Improper blade for cutting operation. | Check Machinist’s Handbook for | |

blade recommendations. | ||

| ||

|

| |

Downfeed rate too fast. | Reduce downfeed rate. | |

|

| |

Blade tension too low. | Increase blade tension. | |

|

|

18