7. Open the valve on the hydraulic cylinder to allow the bow to descend in a gradual and controlled manner.

8. The machine will shut off at the completion of the cut. Turn off the coolant flow, and remove the workpiece.

9. Return the bow to vertical position for the next cut.

Maintenance

Before doing maintenance |

|

on the machine, disconnect it from the |

|

electrical supply by pulling out the plug or |

|

switching off the main switch. Failure to |

|

comply may cause serious injury. |

|

Clean the band saw regularly after each day’s |

|

work. Clear metal shavings with the provided |

|

brush, do not use your hands. Do not use |

|

compressed air. |

|

To prevent corrosion of machined surfaces |

|

when a soluble oil is used as coolant, pay |

|

particular attention to wiping dry the surfaces |

|

where fluid accumulates and does not evaporate |

|

quickly, such as between the machine bed and |

|

vise. |

|

If the power cord is worn, cut, or damaged in |

|

any way, have it replaced immediately. |

|

All ball bearings are permanently lubricated and |

|

sealed. They require no further lubrication. |

|

Grease the vise lead screw as needed. |

|

Place a thin coat of oil on the bed surface on |

|

which the vise jaw slides. |

|

Maintain coolant level. Low coolant level can |

|

cause foaming and high blade temperatures. |

|

Replace dirty coolant; dirty or weak coolant can |

|

clog the pump, cause crooked cuts, a low |

|

cutting rate and/or permanent blade damage. To |

|

fill the tank, remove the filter cup and pour |

|

coolant into the hole. A “Hi/Lo” mark on the tank |

|

indicates proper level (see Figure 5). |

|

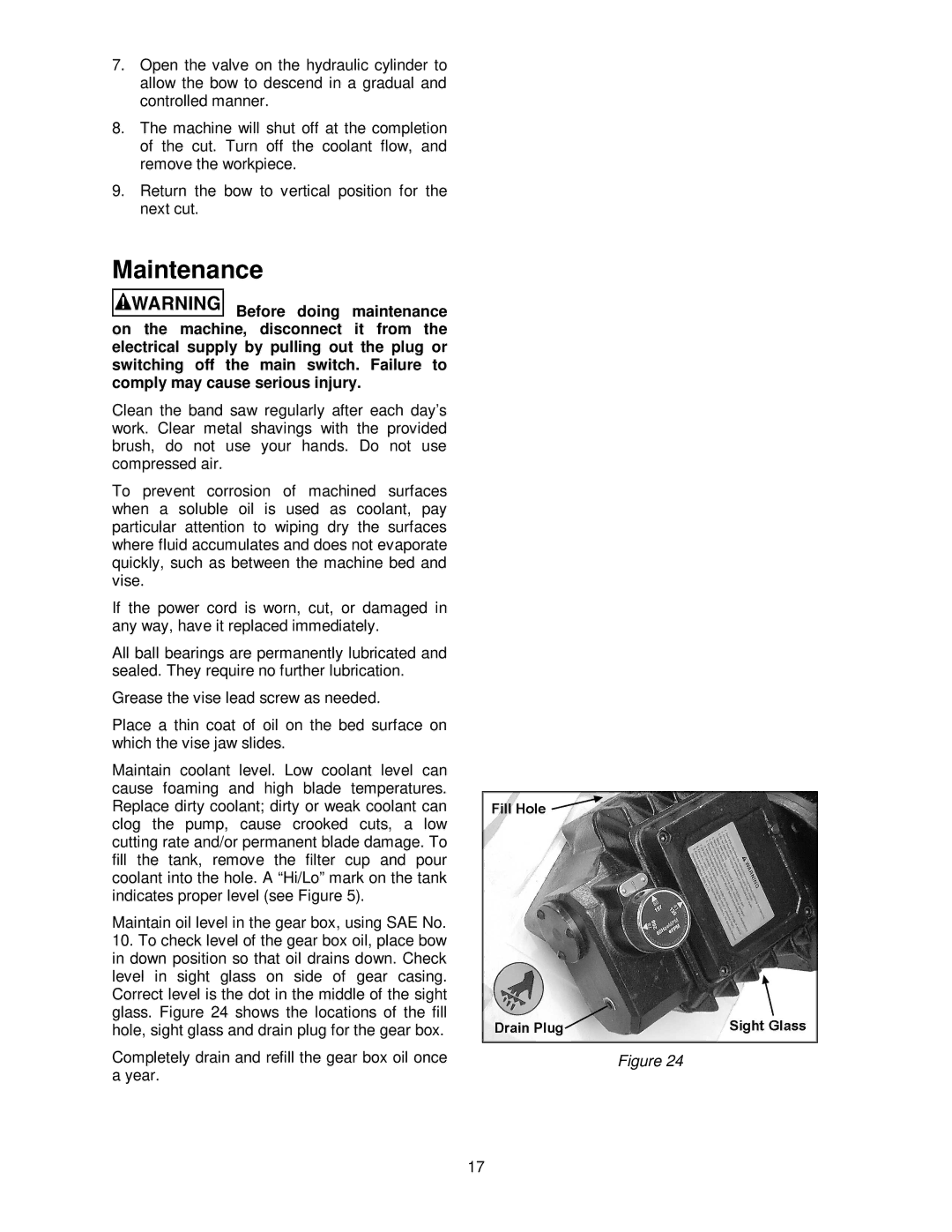

Maintain oil level in the gear box, using SAE No. |

|

10. To check level of the gear box oil, place bow |

|

in down position so that oil drains down. Check |

|

level in sight glass on side of gear casing. |

|

Correct level is the dot in the middle of the sight |

|

glass. Figure 24 shows the locations of the fill |

|

hole, sight glass and drain plug for the gear box. |

|

Completely drain and refill the gear box oil once | Figure 24 |

a year. |

|

17