1560 Series, 15602668, 15603068 specifications

The Johnson Hardware 1560 Series is a premier choice for homeowners and contractors seeking high-quality sliding door hardware solutions. Designed to accommodate various door types, this series boasts an array of features and characteristics that ensure optimal performance and aesthetics.One of the standout features of the Johnson Hardware 1560 Series is its robust construction. Crafted from high-grade materials, the hardware is built to withstand the rigors of daily use while maintaining a sleek appearance. The components are engineered for durability, ensuring that they remain functional and visually appealing even after years of service.

The 1560 Series includes models such as the 15602668 and 15603068, which offer different lengths and configurations to meet a variety of project requirements. Each model is designed to handle doors weighing up to 150 pounds, making them suitable for both residential and commercial applications. This versatility allows users to select the appropriate hardware for their specific needs, ensuring a perfect fit for any sliding door setup.

Technological innovation is at the forefront of the Johnson Hardware 1560 Series. The smooth-glide track system minimizes friction, ensuring effortless door operation. This feature is especially beneficial in high-traffic areas where frequent use of sliding doors can lead to wear and tear. The precision-engineered rollers are designed to provide silent operation, making the opening and closing of doors a seamless experience.

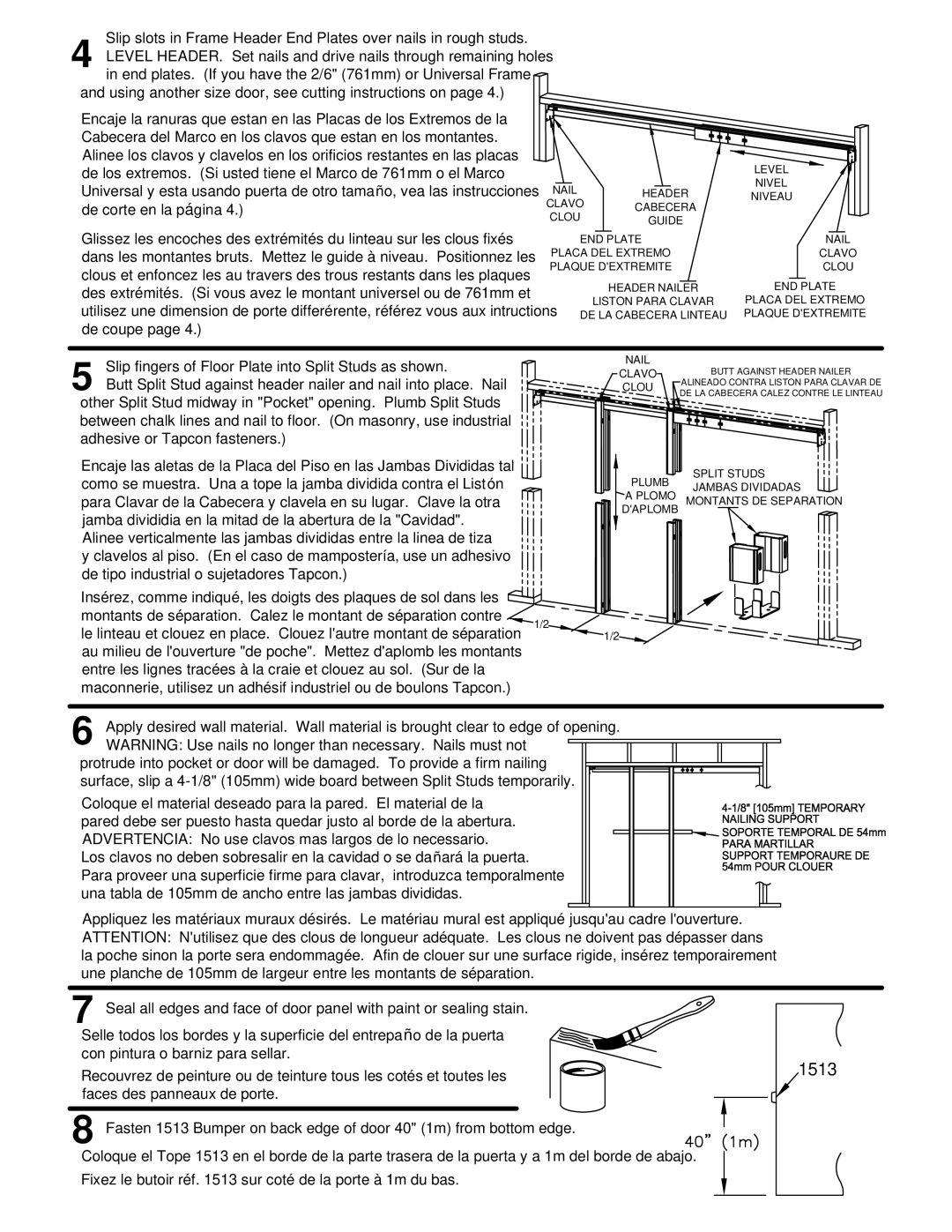

Installation is another area where the Johnson Hardware 1560 Series excels. The hardware comes with clear instructions and all necessary components, making the installation process straightforward, even for DIY enthusiasts. The adjustable components allow for easy customization during installation, ensuring that the doors hang perfectly and operate smoothly.

Aesthetic appeal is also a key consideration in the design of the 1560 Series. Available in multiple finishes, including brushed nickel and oil-rubbed bronze, these hardware options can complement a wide range of interior styles, from modern to rustic. This variety ensures that homeowners can achieve their desired look without sacrificing functionality.

In summary, the Johnson Hardware 1560 Series, including the models 15602668 and 15603068, stands out for its durability, ease of installation, and innovative technology. These sliding door hardware solutions are perfect for those seeking reliable and stylish options for their homes or businesses, making the 1560 Series a top choice in the marketplace.