Operator’s manual EPA

Symbols

KEY TO SYMBOLS

Contents

CONTENTS

Note the following before starting

KEY TO SYMBOLS

Dear customer

INTRODUCTION

What is what on the clearing saw? BC

WHAT IS WHAT?

6 - English

What is what on the clearing saw? FC 2145, FC 2145 S, FC 2145 W

Decompression valve FC 2145 S, FC 2145 W

What is what on the clearing saw? CC

Personal protective equipment

GENERAL SAFETY PRECAUTIONS

WARNING! Listen out for warning signals or

WARNING! The ignition system of this

A BA B

Machine′s safety equipment

WARNING! Never use a machine with faulty

Vibration damping system

Cutting attachment guard

Quick release

Muffler

Locking screw

Locking nut

WARNING! Mufflers fitted with catalytic

WARNING! The inside of the muffler contain

WARNING! Using an incorrect cutting

Cutting equipment

General rules

WARNING! Always stop the engine before

Trimmer head

Sharpening the saw blade

Assembling the handlebar and throttle FC 2145, FC 2145 S, FC 2145 W

ASSEMBLY

Transport position, handlebar

Assembling the handlebar and throttle BC 2145, CC

Assembling the cutting equipment

L M C A

WARNING! When fitting the cutting

N E F P BA C

Fitting the trimmer guard and trimmer head Trimmy SII

Fitting the blade guard and saw blade

L M C A

H P B C

Fitting other guards and cutting attachments

Adjusting the harness and clearing saw

Standard harness

WARNING! When using a clearing saw it

2 Grass clearing

Vector harness

FUEL HANDLING

Fuel safety

Fuel

WARNING! Take care when handling fuel

WARNING! Taking the following precautions will lessen the risk of fire

Fueling

WARNING! The catalytic converter muffler

Do not smoke or place hot objects near fuel

Check before starting

STARTING AND STOPPING

Starting and stopping

WARNING! The complete clutch cover and

Starting

WARNING! When the engine is started with

Stopping

Heated handles FC 2145 W

WARNING! Neither the operator of the

WORKING TECHNIQUES

General working instructions

WARNING! Watch out for thrown objects

Working methods

WARNING! Sometimes branches or grass

WARNING! Machines fitted with saw blades

Brush cutting with a saw blade

Grass clearing using a grass blade

Clearing

Trimming

Cutting

Sweeping

WARNING! If the idle speed cannot be

MAINTENANCE

Carburetor

FC 2145, FC 2145 S, FC 2145 W Speed control at 13500 rpm

Setting procedure without a load Blade can be used

Setting procedure with a load Trimmer head should be used

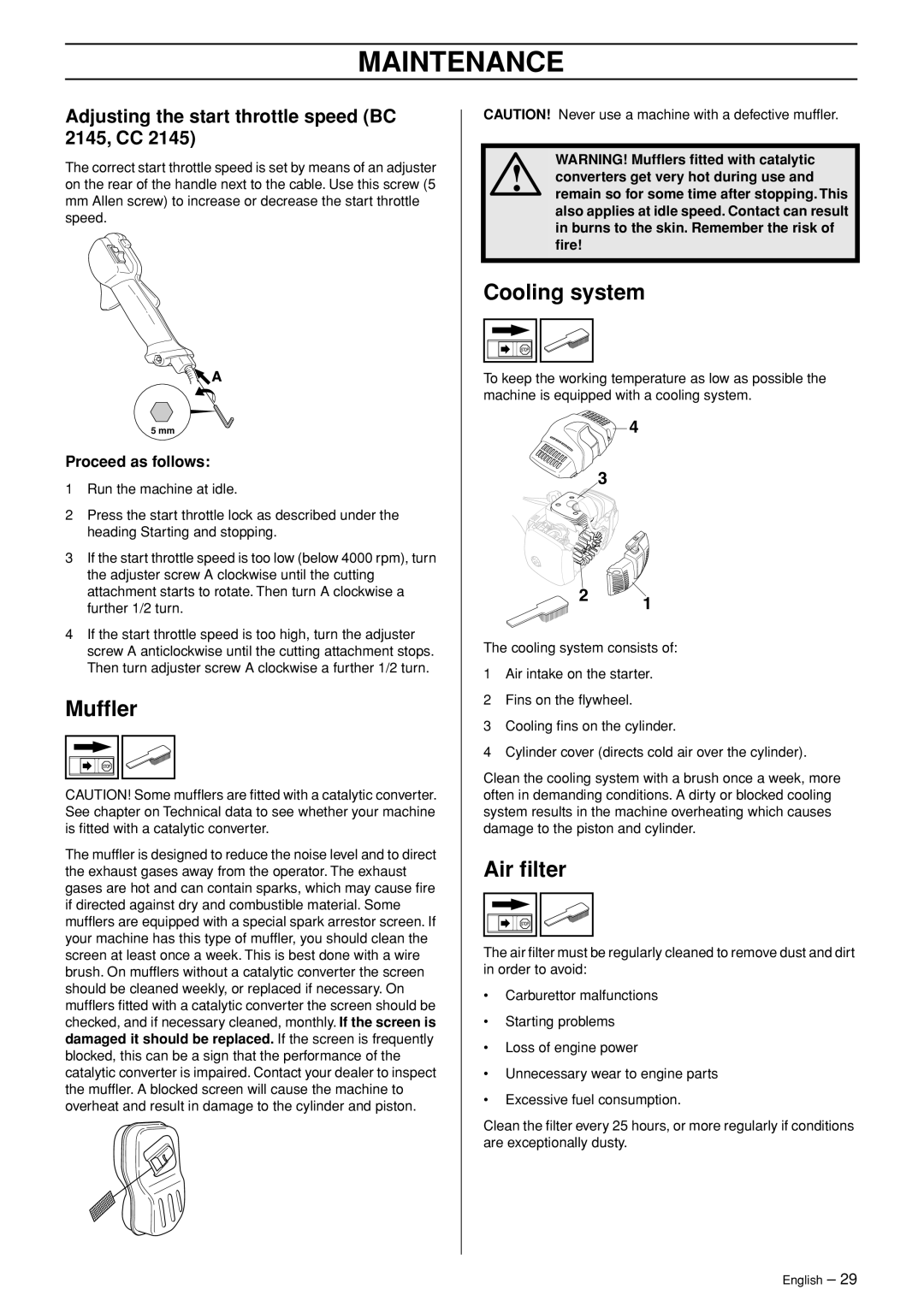

Cooling system

Muffler

Air filter

Proceed as follows

Drive shaft

Bevel gear

Spark plug

Cleaning the air filter

Temperature 5C 41F or colder

Winter use

Maintenance

Maintenance schedule

maintenance

Daily

Technical data

TECHNICAL DATA

Weight

FC 2145 S

Weight

Type

Approved accessories

Cutting attachment guard, Art. no

FC 2145, FC 2145 S, FC 2145 W

YOUR WARRANTY RIGHTS AND OBLIGATIONS

FEDERAL EMISSION CONTROL WARRANTY STATEMENT

20mm

Poly Trim

6 Nm

095-.130

Trimmy SII

7,0 m

~ 3,5 m

Page

1,1 Kw

Auto

1,1 Kw

2,7-3,3 mm

10 m

Tap n’Go 45 Spin

10 cm 4,3 m

2,7-3,3 mm

´z+Rvy¶5s¨ ´z+Rvy¶5s¨

Page

1150868-95 ´z+Rvy¶5s¨ ´z+Rvy¶5s¨