[i!i !! :i :_!! :i :_!i SECTION 2

HOW YOUR WATER SOFTENER WORKS

B. SOFT WATER SERVICE and REGENERATION

REGENERATION

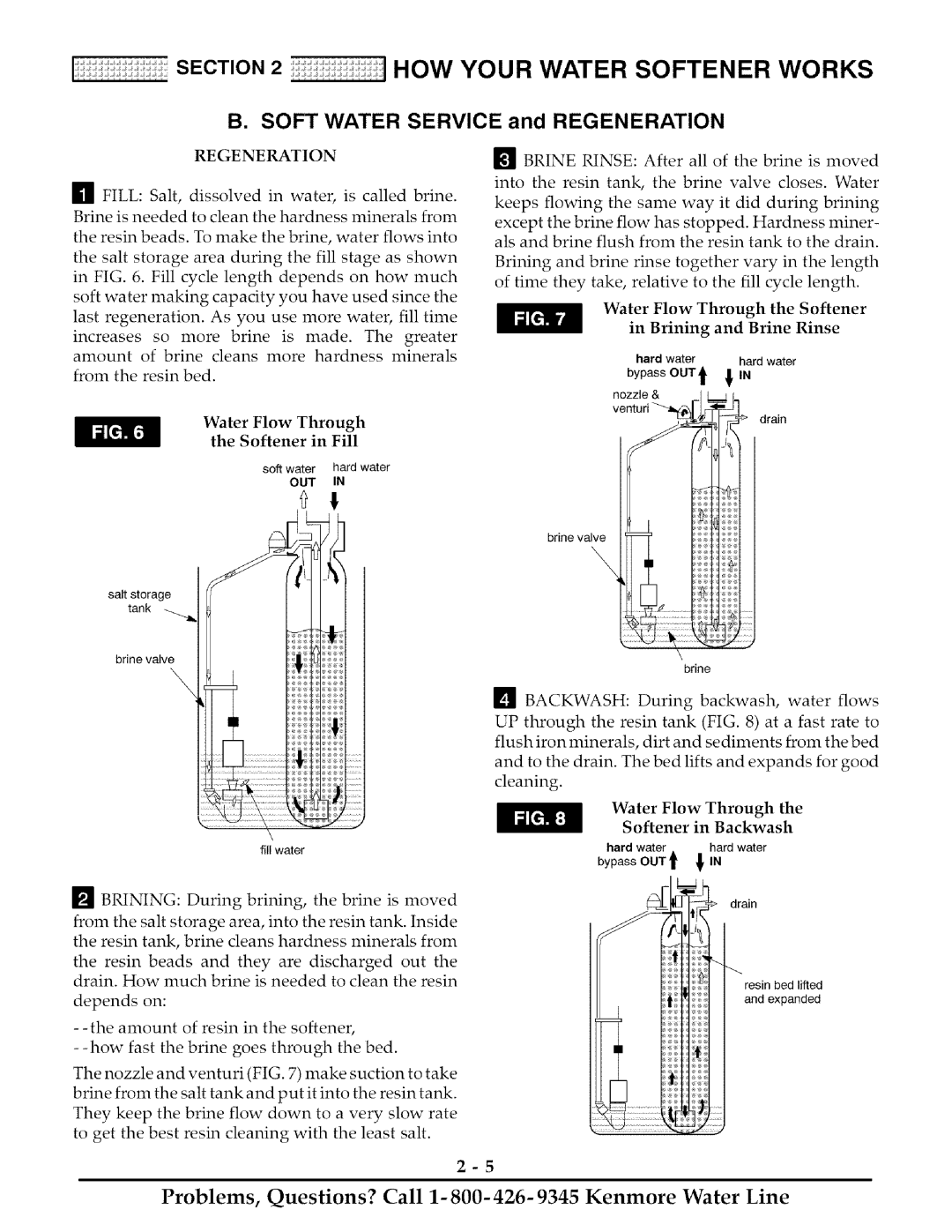

[] FILL: Salt, dissolved in water, is called brine.

Brine is needed to clean the hardness minerals from the resin beads. To make the brine, water flows into the salt storage area during the fill stage as shown

in FIG. 6. Fill cycle length depends on how much soft water making capacity you have used since the

last regeneration. As you use more water, fill time

increases so more brine is made. The greater

amount of brine cleans more hardness minerals from the resin bed.

Water Flow Through

the Softener in Fill

soft water hard water

OUT IN

[] BRINE RINSE: After all of the brine is moved into the resin tank, the brine valve closes. Water keeps flowing the same way it did during brining

except the brine flow has stopped. Hardness miner- als and brine flush from the resin tank to the drain.

Brining and brine rinse together vary in the length of time they take, relative to the fill cycle length.

Water Flow Through the Softener

in Brining and Brine Rinse

hard water | hard water |

bypass OUT t I IN

drain

brine valve

\

salt storage tank

brine valve

brine

fill water

BRINING: During brining, the brine is moved

from the salt storage area, into the resin tank. Inside

the resin tank, brine cleans hardness minerals from

the resin beads and they are discharged out the drain. How much brine is needed to clean the resin

depends on:

The nozzle and venturi (FIG. 7) make suction to take brine from the salt tank and put it into the resin tank. They keep the brine flow down to a very slow rate to get the best resin cleaning with the least salt.

[] BACKWASH: During backwash, water flows

UP through the resin tank (FIG. 8) at a fast rate to

flush iron minerals, dirt and sediments from the bed and to the drain. The bed lifts and expands for good cleaning.

Water Flow Through the

Softener in Backwash

hard | water | hard water |

bypass | OUT t | fIN |

|

| drain |

?l

Problems, Questions? Call 1- 800- 426- 9345 Kenmore Water Line