|

|

|

|

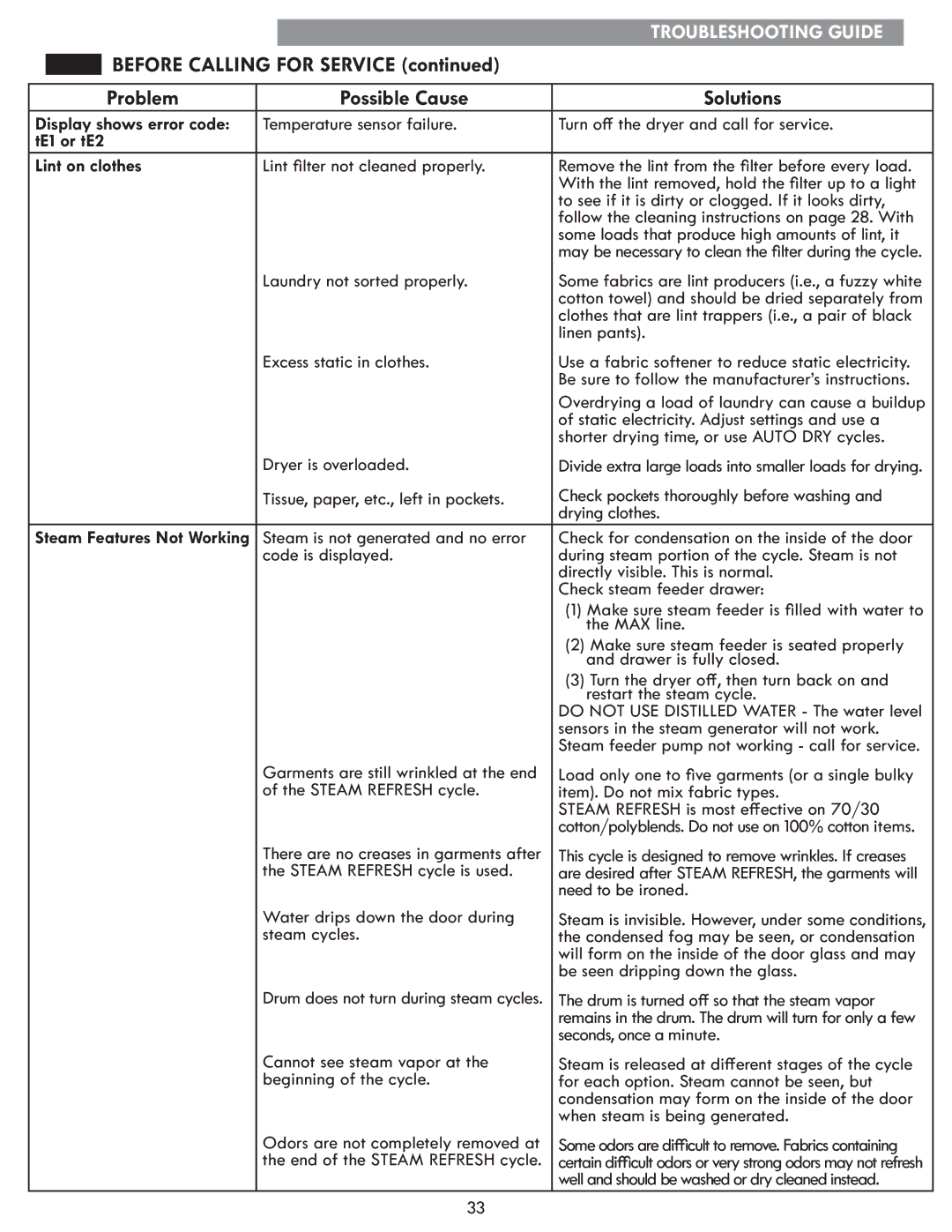

| TROUBLESHOOTING GUIDE |

|

|

| BEFORE CALLING FOR SERVICE (continued) |

|

| ||

|

|

|

| |||

|

|

|

|

|

| |

|

| Problem |

| Possible Cause | Solutions | |

Display shows error code: | Temperature sensor failure. | Turn off the dryer and call for service. | ||||

tE1 or tE2 |

|

|

|

| ||

Lint on clothes | Lint filter not cleaned properly. | Remove the lint from the filter before every load. | ||||

|

|

|

|

| With the lint removed, hold the filter up to a light | |

|

|

|

|

| to see if it is dirty or clogged. If it looks dirty, | |

|

|

|

|

| follow the cleaning instructions on page 28. With | |

|

|

|

|

| some loads that produce high amounts of lint, it | |

|

|

|

|

| may be necessary to clean the filter during the cycle. | |

|

|

| Laundry not sorted properly. | Some fabrics are lint producers (i.e., a fuzzy white | ||

|

|

|

|

| cotton towel) and should be dried separately from | |

|

|

|

|

| clothes that are lint trappers (i.e., a pair of black | |

|

|

|

|

| linen pants). | |

|

|

| Excess static in clothes. | Use a fabric softener to reduce static electricity. | ||

|

|

|

|

| Be sure to follow the manufacturer’s instructions. | |

|

|

|

|

| Overdrying a load of laundry can cause a buildup | |

|

|

|

|

| of static electricity. Adjust settings and use a | |

|

|

|

|

| shorter drying time, or use AUTO DRY cycles. | |

|

|

| Dryer is overloaded. | Divide extra large loads into smaller loads for drying. | ||

|

|

| Tissue, paper, etc., left in pockets. | Check pockets thoroughly before washing and | ||

|

|

|

|

| drying clothes. | |

Steam Features Not Working | Steam is not generated and no error | Check for condensation on the inside of the door | ||||

|

|

| code is displayed. | during steam portion of the cycle. Steam is not | ||

|

|

|

|

| directly visible. This is normal. | |

|

|

|

|

| Check steam feeder drawer: | |

|

|

|

|

| (1) Make sure steam feeder is filled with water to | |

|

|

|

|

| the MAX line. | |

|

|

|

|

| (2) Make sure steam feeder is seated properly | |

|

|

|

|

| and drawer is fully closed. | |

|

|

|

|

| (3) Turn the dryer off, then turn back on and | |

|

|

|

|

| restart the steam cycle. | |

|

|

|

|

| DO NOT USE DISTILLED WATER - The water level | |

|

|

|

|

| sensors in the steam generator will not work. | |

|

|

|

|

| Steam feeder pump not working - call for service. | |

|

|

| Garments are still wrinkled at the end | Load only one to five garments (or a single bulky | ||

|

|

| of the STEAM REFRESH cycle. | item). Do not mix fabric types. | ||

|

|

|

|

| STEAM REFRESH is most effective on 70/30 | |

|

|

|

|

| cotton/polyblends. Do not use on 100% cotton items. | |

|

|

| There are no creases in garments after | This cycle is designed to remove wrinkles. If creases | ||

|

|

| the STEAM REFRESH cycle is used. | are desired after STEAM REFRESH, the garments will | ||

|

|

|

|

| need to be ironed. | |

|

|

| Water drips down the door during | Steam is invisible. However, under some conditions, | ||

|

|

| steam cycles. | the condensed fog may be seen, or condensation | ||

|

|

|

|

| will form on the inside of the door glass and may | |

|

|

|

|

| be seen dripping down the glass. | |

|

|

| Drum does not turn during steam cycles. | The drum is turned off so that the steam vapor | ||

|

|

|

|

| remains in the drum. The drum will turn for only a few | |

|

|

|

|

| seconds, once a minute. | |

|

|

| Cannot see steam vapor at the | Steam is released at different stages of the cycle | ||

|

|

| beginning of the cycle. | for each option. Steam cannot be seen, but | ||

|

|

|

|

| condensation may form on the inside of the door | |

|

|

|

|

| when steam is being generated. | |

|

|

| Odors are not completely removed at | Some odors are difficult to remove. Fabrics containing | ||

|

|

| the end of the STEAM REFRESH cycle. | certain difficult odors or very strong odors may not refresh | ||

|

|

|

|

| well and should be washed or dry cleaned instead. | |

33