BAC-10000 specifications

The KMC BAC-10000 is a cutting-edge building automation controller designed to offer exceptional performance in monitoring and controlling HVAC systems, lighting, and various other building systems. This advanced controller is engineered to enhance energy efficiency, improve occupant comfort, and provide streamlined building management capabilities.One of the main features of the KMC BAC-10000 is its versatility. It supports a wide variety of communication protocols, including BACnet, Modbus, and LonWorks. This multi-protocol capability allows for seamless integration with existing building systems, ensuring that users can easily incorporate the BAC-10000 into their building management setup without the need for additional hardware or extensive modification.

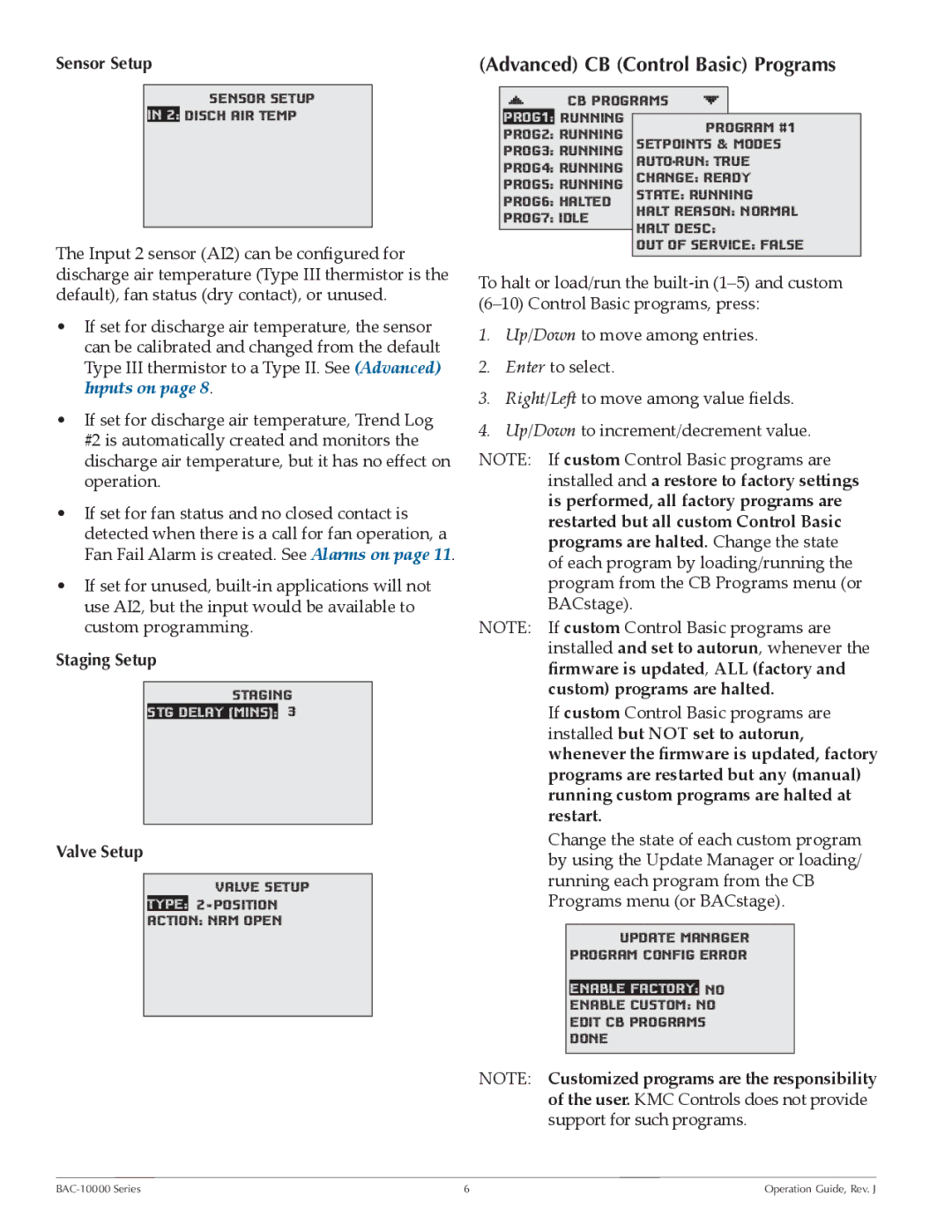

The controller is equipped with an intuitive user interface that simplifies the management of building systems. It includes a graphical display that provides real-time data, enabling operators to monitor system performance, adjust settings, and troubleshoot issues with ease. This user-friendly design promotes efficient operation and reduces the learning curve for new users.

In terms of technical specifications, the BAC-10000 boasts a powerful microprocessor and an extensive range of I/O points, allowing it to handle large and complex building automation tasks. With support for both digital and analog inputs and outputs, users can customize their setup to meet specific operational requirements.

Another standout feature of the KMC BAC-10000 is its advanced data logging capabilities. The controller can record historical data for various parameters, which can be crucial for performance analysis and optimization. This functionality enables facility managers to identify patterns, predict maintenance needs, and ultimately enhance the overall efficiency of their systems.

Security is also a priority with the BAC-10000, as it includes multiple layers of security protocols to protect against unauthorized access and tampering. This ensures that sensitive building management data remains safe and that users can operate the controller confidently.

In conclusion, the KMC BAC-10000 is a robust and flexible building automation controller that offers extensive features and technologies for effective building management. Its multi-protocol support, user-friendly interface, advanced data logging, and emphasis on security make it a top choice for modern building automation needs. By choosing the BAC-10000, facility managers can optimize energy usage, improve occupant comfort, and streamline operations within their buildings.