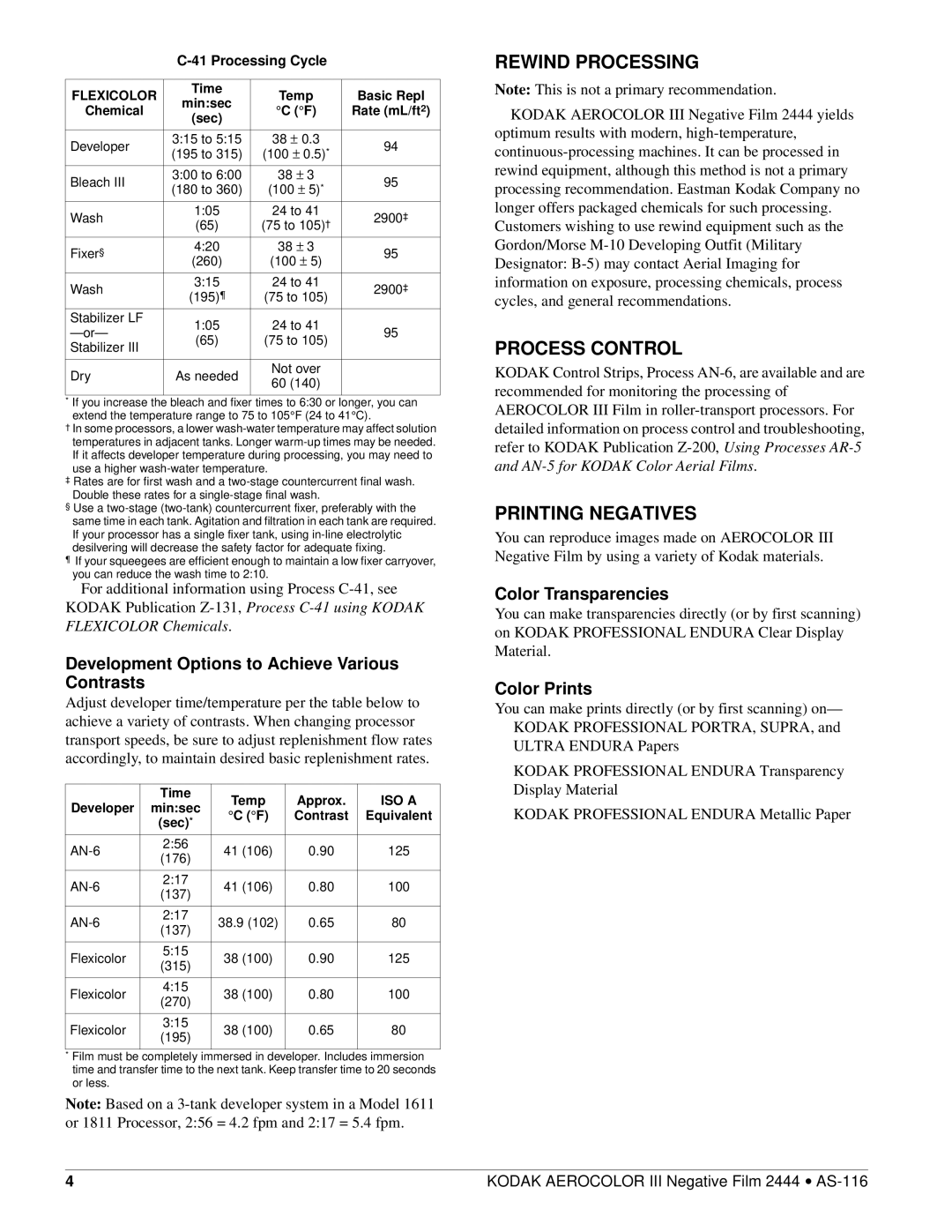

C-41 Processing Cycle

FLEXICOLOR | Time | Temp | Basic Repl | |

min:sec | ||||

Chemical | °C (°F) | Rate (mL/ft2) | ||

(sec) | ||||

|

|

| ||

|

|

|

| |

Developer | 3:15 to 5:15 | 38 ± 0.3 | 94 | |

(195 to 315) | (100 ± 0.5)* | |||

|

| |||

Bleach III | 3:00 to 6:00 | 38 ± 3 | 95 | |

(180 to 360) | (100 ± 5)* | |||

|

| |||

Wash | 1:05 | 24 to 41 | 2900‡ | |

(65) | (75 to 105)† | |||

|

| |||

Fixer§ | 4:20 | 38 ± 3 | 95 | |

(260) | (100 ± 5) | |||

|

| |||

|

|

|

| |

Wash | 3:15 | 24 to 41 | 2900‡ | |

(195)¶ | (75 to 105) | |||

|

| |||

Stabilizer LF | 1:05 | 24 to 41 |

| |

95 | ||||

(65) | (75 to 105) | |||

Stabilizer III |

| |||

|

|

| ||

|

|

|

| |

Dry | As needed | Not over |

| |

60 (140) |

| |||

|

|

| ||

|

|

|

|

*If you increase the bleach and fixer times to 6:30 or longer, you can

extend the temperature range to 75 to 105°F (24 to 41°C).

†In some processors, a lower

If it affects developer temperature during processing, you may need to use a higher

‡Rates are for first wash and a

Double these rates for a

§Use a

If your processor has a single fixer tank, using

¶If your squeegees are efficient enough to maintain a low fixer carryover, you can reduce the wash time to 2:10.

For additional information using Process

FLEXICOLOR Chemicals.

Development Options to Achieve Various Contrasts

Adjust developer time/temperature per the table below to achieve a variety of contrasts. When changing processor transport speeds, be sure to adjust replenishment flow rates accordingly, to maintain desired basic replenishment rates.

| Time | Temp | Approx. | ISO A | |

Developer | min:sec | ||||

°C (°F) | Contrast | Equivalent | |||

| (sec)* | ||||

|

|

|

| ||

2:56 | 41 (106) | 0.90 | 125 | ||

(176) | |||||

|

|

|

| ||

|

|

|

|

| |

2:17 | 41 (106) | 0.80 | 100 | ||

(137) | |||||

|

|

|

| ||

|

|

|

|

| |

2:17 | 38.9 (102) | 0.65 | 80 | ||

(137) | |||||

|

|

|

| ||

|

|

|

|

| |

Flexicolor | 5:15 | 38 (100) | 0.90 | 125 | |

(315) | |||||

|

|

|

| ||

|

|

|

|

| |

Flexicolor | 4:15 | 38 (100) | 0.80 | 100 | |

(270) | |||||

|

|

|

| ||

|

|

|

|

| |

Flexicolor | 3:15 | 38 (100) | 0.65 | 80 | |

(195) | |||||

|

|

|

| ||

|

|

|

|

|

*Film must be completely immersed in developer. Includes immersion time and transfer time to the next tank. Keep transfer time to 20 seconds or less.

Note: Based on a

REWIND PROCESSING

Note: This is not a primary recommendation.

KODAK AEROCOLOR III Negative Film 2444 yields optimum results with modern,

PROCESS CONTROL

KODAK Control Strips, Process

PRINTING NEGATIVES

You can reproduce images made on AEROCOLOR III Negative Film by using a variety of Kodak materials.

Color Transparencies

You can make transparencies directly (or by first scanning) on KODAK PROFESSIONAL ENDURA Clear Display Material.

Color Prints

You can make prints directly (or by first scanning) on— KODAK PROFESSIONAL PORTRA, SUPRA, and ULTRA ENDURA Papers

KODAK PROFESSIONAL ENDURA Transparency Display Material

KODAK PROFESSIONAL ENDURA Metallic Paper

4 | KODAK AEROCOLOR III Negative Film 2444 • |