Effects of Viewing Conditions

Under certain types of illumination, the hue of prints on EKTAMAX RA Paper can appear warm. A

To evaluate and display prints, use light sources such as tungsten and tungsten halogen/quartz halogen. These light sources provide a continuous frequency distribution of energy in the visible spectrum, and the image will appear neutral.

A good average viewing condition is a light source with a color temperature of 5000 ± 1000 K, a Color Rendering Index (CRI) of 85 to 100, and an illuminance of at least

50footcandles (538 lux). Fluorescent lamps such as the cool white deluxe lamp (made by several manufacturers) meet these conditions. You can also use warmer lamps, such as the Phillips 5000 K Ultralume, or a mixture of incandescent and fluorescent lamps. For each pair of

For consistency, labs should always evaluate print quality under the same type of lighting conditions that will be used for print viewing and display.

Effects of Storage Conditions

When kept under refrigerated conditions (13°C [55°F] or lower), this paper can age for 18 months and still be within limits for hue. As unexposed, unprocessed paper ages, its hue moves in a green direction.

Effects of Processing Problems

Severe developer oxidation or low processor utilization will produce a slightly pink (magenta) hue in images on EKTAMAX RA Paper. Extreme contamination of the developer with

The one condition that process controls strips do not show very well is the formation of leuco cyan dye. With color papers, a slight level of leuco cyan dye can be tolerated in prints, and will show up in the control plots to a very limited degree. However, even low levels of leuco cyan dye can cause a red hue in images on EKTAMAX RA Paper.

The following section, “Process Troubleshooting,” describes ways to avoid and correct process problems that cause a hue shift in EKTAMAX RA Paper.

PROCESS TROUBLESHOOTING

Images on EKTAMAX RA Professional Paper that have a noticeable hue may indicate that your process has a developer or a

![]() Important

Important

Before making any changes to your process, be sure that you are using the appropriate light source to view the prints. An apparent hue shift may be related to viewing conditions.

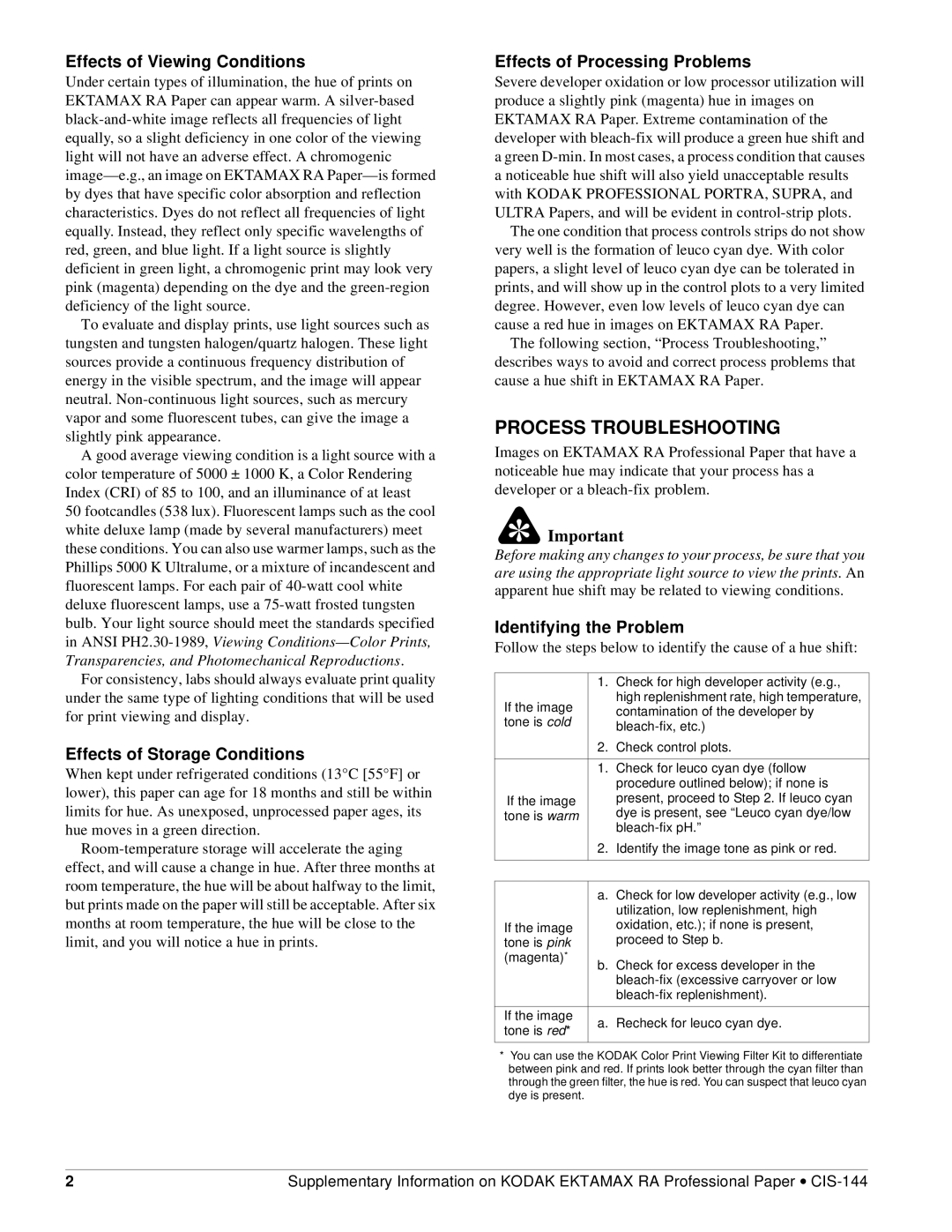

Identifying the Problem

Follow the steps below to identify the cause of a hue shift:

| 1. Check for high developer activity (e.g., | ||

If the image |

| high replenishment rate, high temperature, | |

| contamination of the developer by | ||

tone is cold |

| ||

|

| ||

| 2. | Check control plots. | |

|

| ||

| 1. Check for leuco cyan dye (follow | ||

|

| procedure outlined below); if none is | |

If the image |

| present, proceed to Step 2. If leuco cyan | |

tone is warm |

| dye is present, see “Leuco cyan dye/low | |

|

| ||

| 2. Identify the image tone as pink or red. | ||

|

| ||

|

| ||

| a. Check for low developer activity (e.g., low | ||

|

| utilization, low replenishment, high | |

If the image |

| oxidation, etc.); if none is present, | |

tone is pink |

| proceed to Step b. | |

(magenta)* | b. Check for excess developer in the | ||

|

| ||

|

| ||

|

|

| |

If the image | a. Recheck for leuco cyan dye. | ||

tone is red* | |||

|

| ||

*You can use the KODAK Color Print Viewing Filter Kit to differentiate between pink and red. If prints look better through the cyan filter than through the green filter, the hue is red. You can suspect that leuco cyan dye is present.

2 | Supplementary Information on KODAK EKTAMAX RA Professional Paper • |