Procedure to Confirm Leuco Cyan Dye. If you suspect that leuco cyan dye is the cause of a red image tone, you can bleach a processed print in FLEXICOLOR Bleach III Replenisher to confirm a leuco cyan dye condition. Follow this procedure:

1.Choose a print with a neutral density between 1.20 and 2.00 (1.60 to 1.80 is best). Take density readings of specific areas on the print and mark the spots so that you can take comparison readings after bleaching the print.

2.Immerse the print in FLEXICOLOR Bleach III Replenisher solution at 21°C (70°F) for 2 minutes.

3.Rinse the print for 1 minute in running water at 21 to 43.3°C (70 to 110°F).

4.After rinsing the print, run it through the last wash and the dryer of the same processor used to process the print the first time. It is important to achieve the same surface gloss, because the gloss will affect the density reading.

After bleaching, washing, and drying, read the red and

green densities in the areas you marked. Subtract the original red and green densities of the print from the red and green density readings of the print after bleaching. Then subtract the green density difference from the red density difference. If the answer is greater than 0.10, leuco cyan dye is confirmed.

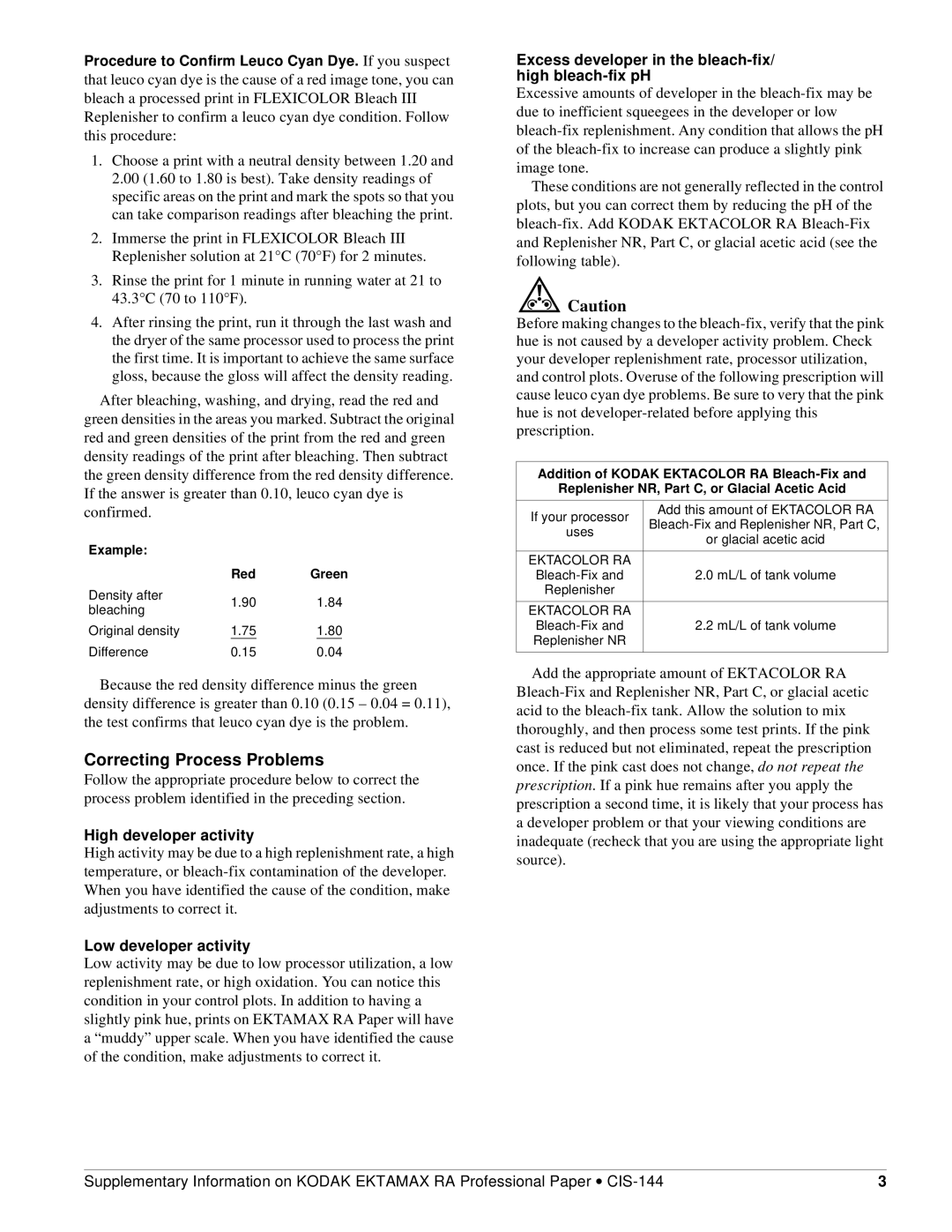

Example: |

|

| |

| Red | Green | |

Density after | 1.90 | 1.84 | |

bleaching | |||

|

| ||

Original density | 1.75 | 1.80 | |

Difference | 0.15 | 0.04 |

Because the red density difference minus the green density difference is greater than 0.10 (0.15 – 0.04 = 0.11), the test confirms that leuco cyan dye is the problem.

Correcting Process Problems

Follow the appropriate procedure below to correct the process problem identified in the preceding section.

High developer activity

High activity may be due to a high replenishment rate, a high temperature, or

Low developer activity

Low activity may be due to low processor utilization, a low replenishment rate, or high oxidation. You can notice this condition in your control plots. In addition to having a slightly pink hue, prints on EKTAMAX RA Paper will have a “muddy” upper scale. When you have identified the cause of the condition, make adjustments to correct it.

Excess developer in the bleach-fix/ high bleach-fix pH

Excessive amounts of developer in the

These conditions are not generally reflected in the control plots, but you can correct them by reducing the pH of the

![]() Caution

Caution

Before making changes to the

Addition of KODAK EKTACOLOR RA

Replenisher NR, Part C, or Glacial Acetic Acid

If your processor | Add this amount of EKTACOLOR RA | |

uses | ||

or glacial acetic acid | ||

| ||

|

| |

EKTACOLOR RA |

| |

2.0 mL/L of tank volume | ||

Replenisher |

| |

EKTACOLOR RA |

| |

2.2 mL/L of tank volume | ||

Replenisher NR |

| |

|

|

Add the appropriate amount of EKTACOLOR RA

Supplementary Information on KODAK EKTAMAX RA Professional Paper • | 3 |