Leuco cyan dye/low bleach-fix pH

Leuco cyan dye is due to a low pH in the bleach-fix caused by a high replenishment rate or incorrect start-up (fresh tank) mixing procedure. It results in a warm reddish image tone due to some of the cyan dye being converted into an invisible state. Leuco cyan dye conditions that cause problems with color paper are also reflected in control plots (the black patch tends to have a lower red density than green and blue). EKTAMAX RA Paper will generally alert you to this condition before you see it on color paper production or in your control plots.

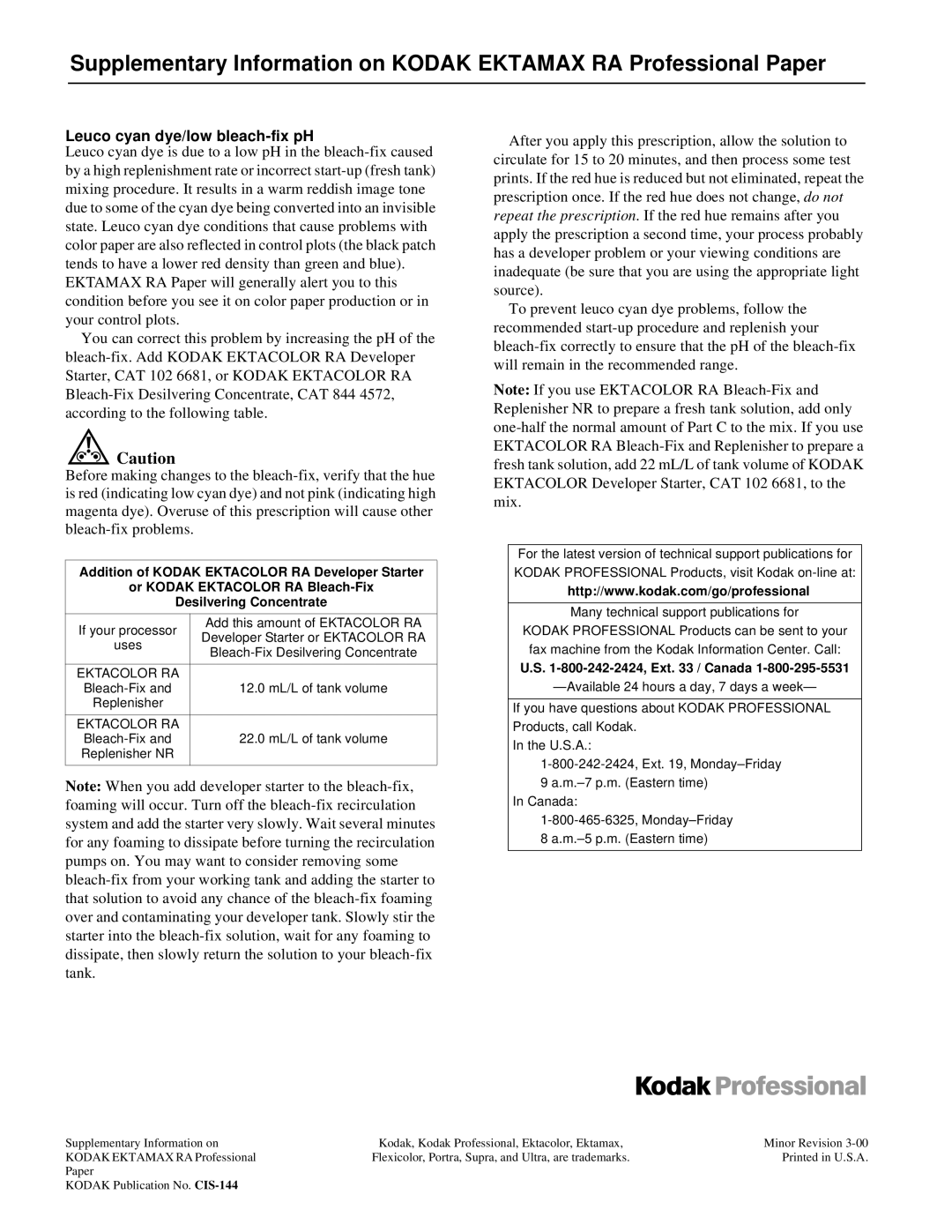

You can correct this problem by increasing the pH of the bleach-fix. Add KODAK EKTACOLOR RA Developer Starter, CAT 102 6681, or KODAK EKTACOLOR RA Bleach-Fix Desilvering Concentrate, CAT 844 4572, according to the following table.

Caution

Caution

Before making changes to the bleach-fix, verify that the hue is red (indicating low cyan dye) and not pink (indicating high magenta dye). Overuse of this prescription will cause other bleach-fix problems.

Addition of KODAK EKTACOLOR RA Developer Starter

or KODAK EKTACOLOR RA Bleach-Fix

Desilvering Concentrate

| If your processor | Add this amount of EKTACOLOR RA |

| Developer Starter or EKTACOLOR RA |

| uses |

| Bleach-Fix Desilvering Concentrate |

| |

| | |

| EKTACOLOR RA | |

| Bleach-Fix and | 12.0 mL/L of tank volume |

| Replenisher | |

| | |

| EKTACOLOR RA | |

| Bleach-Fix and | 22.0 mL/L of tank volume |

| Replenisher NR | |

| | |

Note: When you add developer starter to the bleach-fix, foaming will occur. Turn off the bleach-fix recirculation system and add the starter very slowly. Wait several minutes for any foaming to dissipate before turning the recirculation pumps on. You may want to consider removing some bleach-fix from your working tank and adding the starter to that solution to avoid any chance of the bleach-fix foaming over and contaminating your developer tank. Slowly stir the starter into the bleach-fix solution, wait for any foaming to dissipate, then slowly return the solution to your bleach-fix tank.

After you apply this prescription, allow the solution to circulate for 15 to 20 minutes, and then process some test prints. If the red hue is reduced but not eliminated, repeat the prescription once. If the red hue does not change, do not repeat the prescription. If the red hue remains after you apply the prescription a second time, your process probably has a developer problem or your viewing conditions are inadequate (be sure that you are using the appropriate light source).

To prevent leuco cyan dye problems, follow the recommended start-up procedure and replenish your bleach-fix correctly to ensure that the pH of the bleach-fix will remain in the recommended range.

Note: If you use EKTACOLOR RA Bleach-Fix and Replenisher NR to prepare a fresh tank solution, add only one-half the normal amount of Part C to the mix. If you use EKTACOLOR RA Bleach-Fix and Replenisher to prepare a fresh tank solution, add 22 mL/L of tank volume of KODAK EKTACOLOR Developer Starter, CAT 102 6681, to the mix.

For the latest version of technical support publications for KODAK PROFESSIONAL Products, visit Kodak on-line at:

http://www.kodak.com/go/professional

Many technical support publications for

KODAK PROFESSIONAL Products can be sent to your fax machine from the Kodak Information Center. Call:

U.S. 1-800-242-2424, Ext. 33 / Canada 1-800-295-5531

—Available 24 hours a day, 7 days a week—

If you have questions about KODAK PROFESSIONAL Products, call Kodak.

In the U.S.A.:

1-800-242-2424, Ext. 19, Monday–Friday 9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, Monday–Friday

8 a.m.–5 p.m. (Eastern time)

![]() Caution

Caution