TROUBLESHOOTING

CATALYST PLUGGING

1.Burning materials that produce a lot of char and fly ash. Do not burn materials such as garbage, gift wrap, cardboard, etc.

2.Burning wet pitchy woods or burning large loads of small diameter wood with the combustor in the op- eration position (without

CATALYST DEACTIVATION

1.Burning large quantities of trash,

CATALYST SUBSTRATE CRACKING

1.Normal operation, as long as combustor remains intact. If cracking causes large pieces to fall out, re- place combustor.

2.Mishandling or abuse. Handle with care.

3.Excessive draft. Correct installation. See Draft Re- quirements, page 11.

CATALYST SUBSTRATE

1.Extreme thermal shock. Combustor is being worked too hard.

2.Excessive draft. Correct installation. See Draft Re- quirements, page 11.

CATALYST PEELING

Extreme Temperatures

TAR AND LIQUID CREOSOTE LEAKING FROM METAL FLUE JOINTS

1. No chimney cap on chimney. Install cap.

2.Metal flue assembled improperly. Top flue sections should be inserted into lower flue sections.

DENSE SMOKE LEAVING CHIMNEY

1.Water vapor (on cold still days water vapor may be mistaken for smoke). Water vapor is normal and should be of little concern.

2.Wet, pitchy woods being burned. Burn dry sea- soned wood only.

3.Bypass in open position. Close bypass.

4.Combustor not functioning. See Catalyst Replace- ment, page 20.

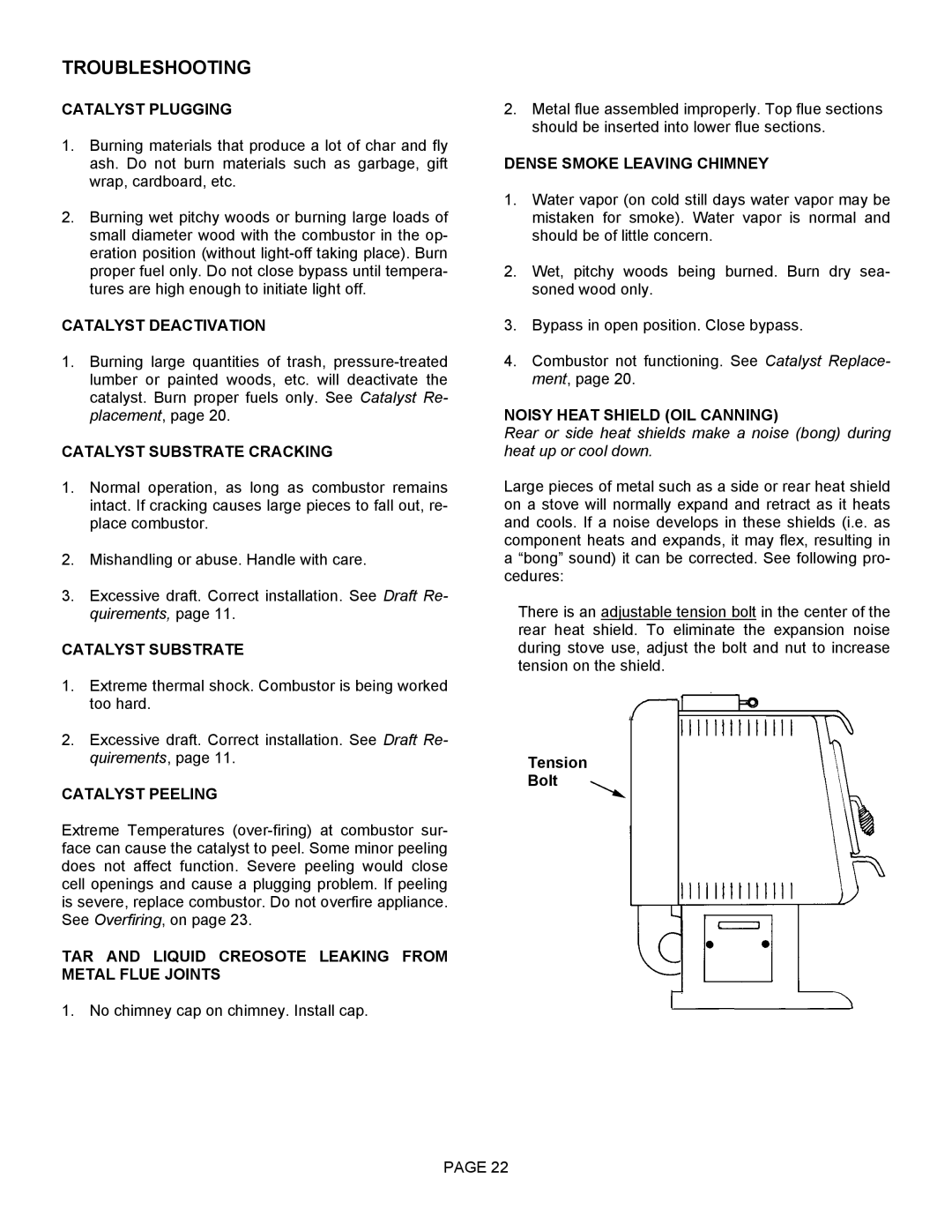

NOISY HEAT SHIELD (OIL CANNING)

Rear or side heat shields make a noise (bong) during heat up or cool down.

Large pieces of metal such as a side or rear heat shield on a stove will normally expand and retract as it heats and cools. If a noise develops in these shields (i.e. as component heats and expands, it may flex, resulting in a “bong” sound) it can be corrected. See following pro- cedures:

There is an adjustable tension bolt in the center of the rear heat shield. To eliminate the expansion noise during stove use, adjust the bolt and nut to increase tension on the shield.

Tension

Bolt

PAGE 22