3.4 Function Check

-Check display and sound

■Check Input and Signal items.

1)TV

2)AV (SCART / CVBS)

3)COMPONENT (480i)

4)RGB (PC : 1024 x 768 @ 60hz) (* RGB input : LD21B only support)

5)HDMI

6)PC Audio In (* except LD21A chassis model)

* Display and Sound check is executed by Remote control.

<Caution>

Not to push the INSTOP key after completion if the function inspection.

4. Total Assembly line process

4.1. Adjustment Preparation

▪ W/B Equipment condition CA210

: CCFL/EEFL

▪ If it is executed W/B adjustment in 2~3 minutes H/run, it is adjusted by Target data

Mode | Temp | Coordinate spec | Target |

| |

Cool | 13,000k | X=0.269 (±0.002) | X=0.271 |

| |

|

| Y=0.273 (±0.002) | Y=0.276 | <Test Signal> | |

Medium | 9,300k | X=0.285 (±0.002) | X=0.287 | Inner pattern | |

Y=0.293 (±0.002) | Y=0.296 | (204gray, | |||

|

| ||||

|

|

|

| 80IRE) | |

Warm | 6,500k | X=0.313 (±0.002) | X=0.315 | ||

Y=0.329 (±0.002) | Y=0.332 |

| |||

|

|

|

▪ Edge LED W/B Table in process of time (LGD module & 65” AUO module)

| Aging |

| Cool | Medium | Warm | |||

GP4 | time | X |

| y | x | y | x | y |

| (Min) | 269 |

| 273 | 285 | 293 | 313 | 329 |

1 | 280 |

| 287 | 296 | 307 | 320 | 337 | |

2 | 279 |

| 285 | 295 | 305 | 319 | 335 | |

3 | 277 |

| 284 | 293 | 304 | 317 | 334 | |

4 | 276 |

| 283 | 292 | 303 | 316 | 333 | |

5 | 274 |

| 280 | 290 | 300 | 314 | 330 | |

6 | 272 |

| 277 | 288 | 297 | 312 | 327 | |

7 | 271 |

| 275 | 287 | 295 | 311 | 325 | |

8 | 270 |

| 274 | 286 | 294 | 310 | 324 | |

9 | Over 120 | 269 |

| 273 | 285 | 293 | 309 | 323 |

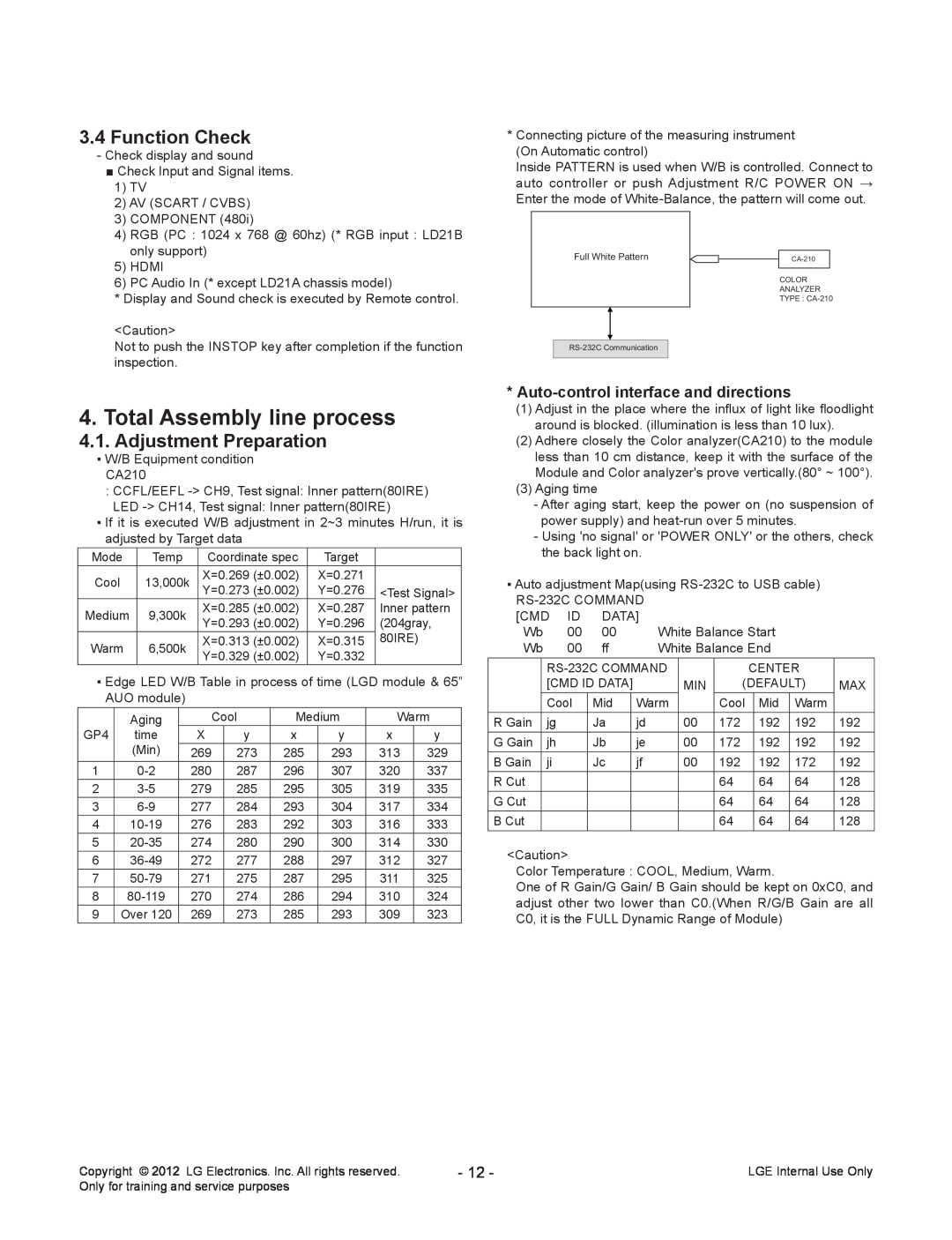

*Connecting picture of the measuring instrument (On Automatic control)

Inside PATTERN is used when W/B is controlled. Connect to auto controller or push Adjustment R/C POWER ON → Enter the mode of

Full White Pattern | |

|

|

COLOR

ANALYZER

TYPE :

*

(1)Adjust in the place where the influx of light like floodlight around is blocked. (illumination is less than 10 lux).

(2)Adhere closely the Color analyzer(CA210) to the module less than 10 cm distance, keep it with the surface of the Module and Color analyzer's prove vertically.(80° ~ 100°).

(3)Aging time

-After aging start, keep the power on (no suspension of power supply) and

-Using 'no signal' or 'POWER ONLY' or the others, check the back light on.

▪ Auto adjustment Map(using |

| ||||||||||

|

|

|

|

|

| ||||||

[CMD ID | DATA] |

|

|

|

|

|

| ||||

Wb | 00 | 00 |

| White Balance Start |

|

| |||||

Wb | 00 | ff | White Balance End |

|

| ||||||

|

|

|

| CENTER |

| ||||||

|

| [CMD ID DATA] |

| MIN |

| (DEFAULT) | MAX | ||||

|

| Cool | Mid |

| Warm |

| Cool | Mid | Warm |

| |

R Gain |

| jg | Ja |

| jd | 00 | 172 |

| 192 | 192 | 192 |

G Gain |

| jh | Jb |

| je | 00 | 172 |

| 192 | 192 | 192 |

B Gain |

| ji | Jc |

| jf | 00 | 192 |

| 192 | 172 | 192 |

R Cut |

|

|

|

|

|

| 64 |

| 64 | 64 | 128 |

G Cut |

|

|

|

|

|

| 64 |

| 64 | 64 | 128 |

B Cut |

|

|

|

|

|

| 64 |

| 64 | 64 | 128 |

<Caution>

Color Temperature : COOL, Medium, Warm.

One of R Gain/G Gain/ B Gain should be kept on 0xC0, and adjust other two lower than C0.(When R/G/B Gain are all C0, it is the FULL Dynamic Range of Module)

Copyright © | LG Electronics. Inc. All rights reserved. | - 12 - | LGE Internal Use Only |

Only for training and service purposes |

|

| |