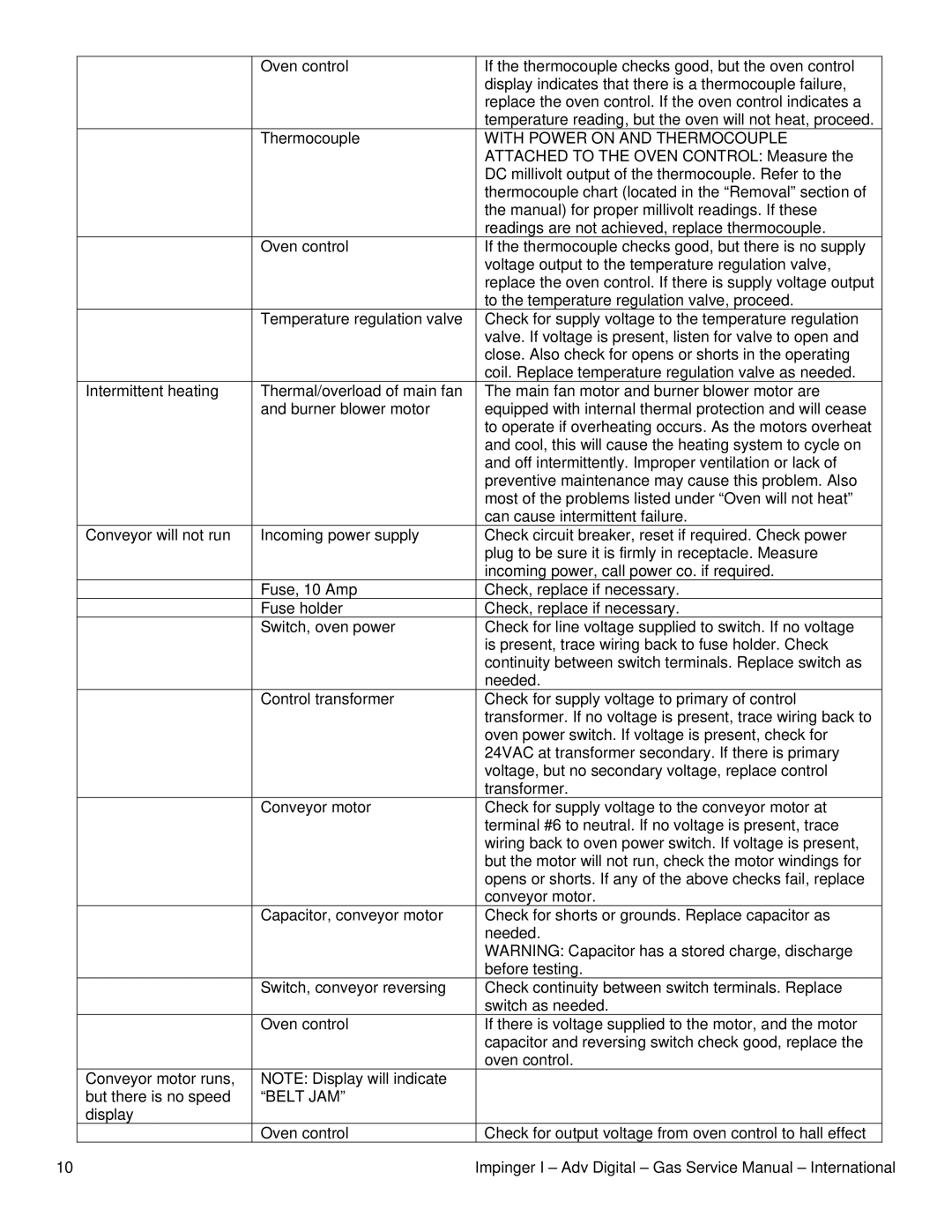

| Oven control | If the thermocouple checks good, but the oven control |

|

| display indicates that there is a thermocouple failure, |

|

| replace the oven control. If the oven control indicates a |

|

| temperature reading, but the oven will not heat, proceed. |

| Thermocouple | WITH POWER ON AND THERMOCOUPLE |

|

| ATTACHED TO THE OVEN CONTROL: Measure the |

|

| DC millivolt output of the thermocouple. Refer to the |

|

| thermocouple chart (located in the “Removal” section of |

|

| the manual) for proper millivolt readings. If these |

|

| readings are not achieved, replace thermocouple. |

| Oven control | If the thermocouple checks good, but there is no supply |

|

| voltage output to the temperature regulation valve, |

|

| replace the oven control. If there is supply voltage output |

|

| to the temperature regulation valve, proceed. |

| Temperature regulation valve | Check for supply voltage to the temperature regulation |

|

| valve. If voltage is present, listen for valve to open and |

|

| close. Also check for opens or shorts in the operating |

|

| coil. Replace temperature regulation valve as needed. |

Intermittent heating | Thermal/overload of main fan | The main fan motor and burner blower motor are |

| and burner blower motor | equipped with internal thermal protection and will cease |

|

| to operate if overheating occurs. As the motors overheat |

|

| and cool, this will cause the heating system to cycle on |

|

| and off intermittently. Improper ventilation or lack of |

|

| preventive maintenance may cause this problem. Also |

|

| most of the problems listed under “Oven will not heat” |

|

| can cause intermittent failure. |

Conveyor will not run | Incoming power supply | Check circuit breaker, reset if required. Check power |

|

| plug to be sure it is firmly in receptacle. Measure |

|

| incoming power, call power co. if required. |

| Fuse, 10 Amp | Check, replace if necessary. |

| Fuse holder | Check, replace if necessary. |

| Switch, oven power | Check for line voltage supplied to switch. If no voltage |

|

| is present, trace wiring back to fuse holder. Check |

|

| continuity between switch terminals. Replace switch as |

|

| needed. |

| Control transformer | Check for supply voltage to primary of control |

|

| transformer. If no voltage is present, trace wiring back to |

|

| oven power switch. If voltage is present, check for |

|

| 24VAC at transformer secondary. If there is primary |

|

| voltage, but no secondary voltage, replace control |

|

| transformer. |

| Conveyor motor | Check for supply voltage to the conveyor motor at |

|

| terminal #6 to neutral. If no voltage is present, trace |

|

| wiring back to oven power switch. If voltage is present, |

|

| but the motor will not run, check the motor windings for |

|

| opens or shorts. If any of the above checks fail, replace |

|

| conveyor motor. |

| Capacitor, conveyor motor | Check for shorts or grounds. Replace capacitor as |

|

| needed. |

|

| WARNING: Capacitor has a stored charge, discharge |

|

| before testing. |

| Switch, conveyor reversing | Check continuity between switch terminals. Replace |

|

| switch as needed. |

| Oven control | If there is voltage supplied to the motor, and the motor |

|

| capacitor and reversing switch check good, replace the |

|

| oven control. |

Conveyor motor runs, | NOTE: Display will indicate |

|

but there is no speed | “BELT JAM” |

|

display |

|

|

| Oven control | Check for output voltage from oven control to hall effect |

10 | Impinger I – Adv Digital – Gas Service Manual – International |