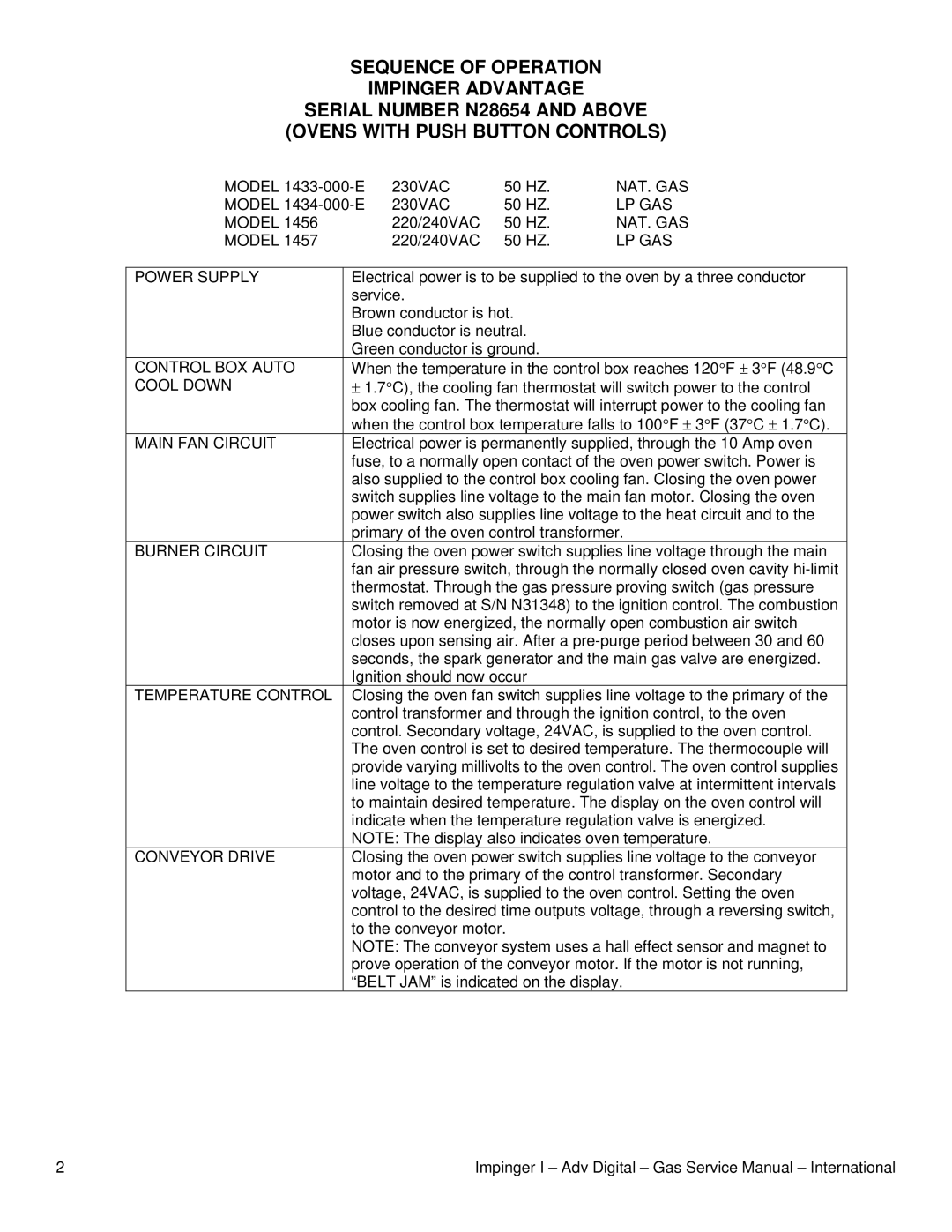

SEQUENCE OF OPERATION

IMPINGER ADVANTAGE

SERIAL NUMBER N28654 AND ABOVE (OVENS WITH PUSH BUTTON CONTROLS)

MODEL | 230VAC | 50 HZ. | NAT. GAS | |

MODEL | 230VAC | 50 HZ. | LP GAS | |

MODEL 1456 |

| 220/240VAC | 50 HZ. | NAT. GAS |

MODEL 1457 |

| 220/240VAC | 50 HZ. | LP GAS |

|

| |||

POWER SUPPLY | Electrical power is to be supplied to the oven by a three conductor | |||

| service. |

|

| |

| Brown conductor is hot. |

| ||

| Blue conductor is neutral. |

| ||

| Green conductor is ground. |

| ||

CONTROL BOX AUTO | When the temperature in the control box reaches 120°F ± 3°F (48.9°C | |||

COOL DOWN | ± 1.7°C), the cooling fan thermostat will switch power to the control | |||

| box cooling fan. The thermostat will interrupt power to the cooling fan | |||

| when the control box temperature falls to 100°F ± 3°F (37°C ± 1.7°C). | |||

MAIN FAN CIRCUIT | Electrical power is permanently supplied, through the 10 Amp oven | |||

| fuse, to a normally open contact of the oven power switch. Power is | |||

| also supplied to the control box cooling fan. Closing the oven power | |||

| switch supplies line voltage to the main fan motor. Closing the oven | |||

| power switch also supplies line voltage to the heat circuit and to the | |||

| primary of the oven control transformer. | |||

BURNER CIRCUIT | Closing the oven power switch supplies line voltage through the main | |||

| fan air pressure switch, through the normally closed oven cavity | |||

| thermostat. Through the gas pressure proving switch (gas pressure | |||

| switch removed at S/N N31348) to the ignition control. The combustion | |||

| motor is now energized, the normally open combustion air switch | |||

| closes upon sensing air. After a | |||

| seconds, the spark generator and the main gas valve are energized. | |||

| Ignition should now occur |

| ||

TEMPERATURE CONTROL | Closing the oven fan switch supplies line voltage to the primary of the | |||

| control transformer and through the ignition control, to the oven | |||

| control. Secondary voltage, 24VAC, is supplied to the oven control. | |||

| The oven control is set to desired temperature. The thermocouple will | |||

| provide varying millivolts to the oven control. The oven control supplies | |||

| line voltage to the temperature regulation valve at intermittent intervals | |||

| to maintain desired temperature. The display on the oven control will | |||

| indicate when the temperature regulation valve is energized. | |||

| NOTE: The display also indicates oven temperature. | |||

CONVEYOR DRIVE | Closing the oven power switch supplies line voltage to the conveyor | |||

| motor and to the primary of the control transformer. Secondary | |||

| voltage, 24VAC, is supplied to the oven control. Setting the oven | |||

| control to the desired time outputs voltage, through a reversing switch, | |||

| to the conveyor motor. |

| ||

| NOTE: The conveyor system uses a hall effect sensor and magnet to | |||

| prove operation of the conveyor motor. If the motor is not running, | |||

| “BELT JAM” is indicated on the display. | |||

2 | Impinger I – Adv Digital – Gas Service Manual – International |