Excalibur® 11018M MR™ | STICK |

|

Basic, Low Hydrogen, Low Alloy Steel SMAW Electrode

(AWS E11018M-H4R)

Excalibur® 11018M MR™ is designed primarily for joining high strength steel types in the as- welded or stress relieved conditions with excellent low temperature impact properties and robust welding procedures.

Advantage Lincoln

Integrated Silicate Technology™

Increased moisture resistance and decreased coating fragility.

Easy Strike™ Tip

Consistent, smooth arc starts.

Square

Focused arc for hard to access welds.

Demanding applications.

Hermetically Sealed Packaging – Easy Open Cans Delivers quality product, performance reliability and consistent results.

ISO 9001 and 14001 Certified

Manufactured to standards for environmental and quality management systems.

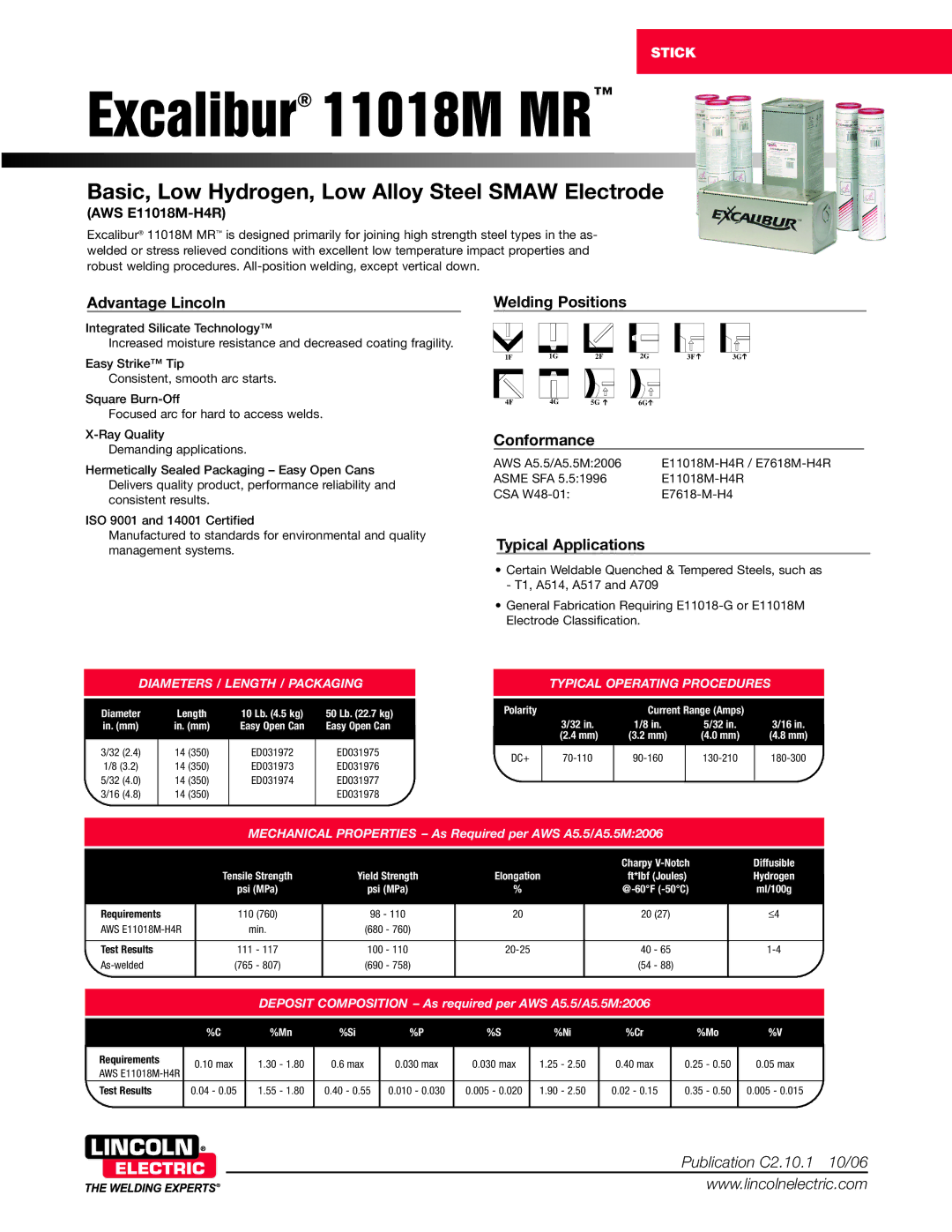

Welding Positions |

|

|

|

| |

1G | 2F | 2G | 3F | ➔ | 3G➔ |

4F | 4G | 5G | ➔ | 6G➔ |

Conformance

AWS A5.5/A5.5M:2006 | |

ASME SFA 5.5:1996 | |

CSA |

Typical Applications

•Certain Weldable Quenched & Tempered Steels, such as - T1, A514, A517 and A709

•General Fabrication Requiring

DIAMETERS / LENGTH / PACKAGING |

| TYPICAL OPERATING PROCEDURES |

|

|

|

Diameter in. (mm)

3/32 (2.4)

1/8 (3.2)

5/32 (4.0) 3/16 (4.8)

Length

in. (mm)

14(350)

14(350)

14(350)

14(350)

10 Lb. (4.5 kg) Easy Open Can

ED031972

ED031973

ED031974

50 Lb. (22.7 kg)Polarity

Easy Open Can |

| |

ED031975 | DC+ | |

ED031976 | ||

| ||

ED031977 |

| |

ED031978 |

|

3/32 in. (2.4 mm)

Current Range (Amps)

1/8 in. |

| 5/32 in. |

(3.2 mm) |

| (4.0 mm) |

| ||

| ||

|

|

|

3/16 in.

(4.8 mm)

MECHANICAL PROPERTIES – As Required per AWS A5.5/A5.5M:2006

|

|

|

|

|

| Charpy | Diffusible | |

| Tensile Strength | Yield Strength | Elongation | ft*lbf (Joules) | Hydrogen | |||

|

|

|

| |||||

| psi (MPa) | psi (MPa) | % | ml/100g | ||||

|

|

|

|

|

|

|

|

|

Requirements | 110 (760) | 98 - 110 | 20 | 20 (27) | ≤4 | |||

AWS | min. | (680 | - 760) |

|

|

|

| |

|

|

|

|

|

|

|

|

|

Test Results | 111 | - 117 | 100 | - 110 | 40 | - 65 | ||

(765 | - 807) | (690 | - 758) |

| (54 | - 88) |

| |

|

|

|

|

|

|

|

|

|

DEPOSIT COMPOSITION – As required per AWS A5.5/A5.5M:2006

| %C | %Mn | %Si | %P | %S | %Ni | %Cr | %Mo | %V | |

|

|

|

|

|

|

|

|

|

| |

Requirements | 0.10 max | 1.30 - 1.80 | 0.6 max | 0.030 max | 0.030 max | 1.25 - 2.50 | 0.40 max | 0.25 - 0.50 | 0.05 max | |

AWS | ||||||||||

|

|

|

|

|

|

|

|

| ||

Test Results | 0.04 - 0.05 | 1.55 - 1.80 | 0.40 - 0.55 | 0.010 - 0.030 | 0.005 - 0.020 | 1.90 - 2.50 | 0.02 - 0.15 | 0.35 - 0.50 | 0.005 - 0.015 | |

|

|

|

|

|

|

|

|

|

|

Publication C2.10.1 10/06

www.lincolnelectric.com