A CLOSER LOOK

ARC PERFORMANCE, CON’T.

Lincoln Nextweld® Innovations for Challenging Applications

Waveform Control Technology® makes it possible to take advantage of Lincoln innovations like these patented processes using the Power MIG® 350MP power source:

For more information see Nextweld ® Document NX-2.10

Power Mode® uses

For more information see Nextweld ® Document NX-2.60

Power Mode reduces spatter and | Power Mode aids bead |

improves bead appearance, | wetting and penetration |

even for low voltage | on aluminum. |

procedures on stainless. |

|

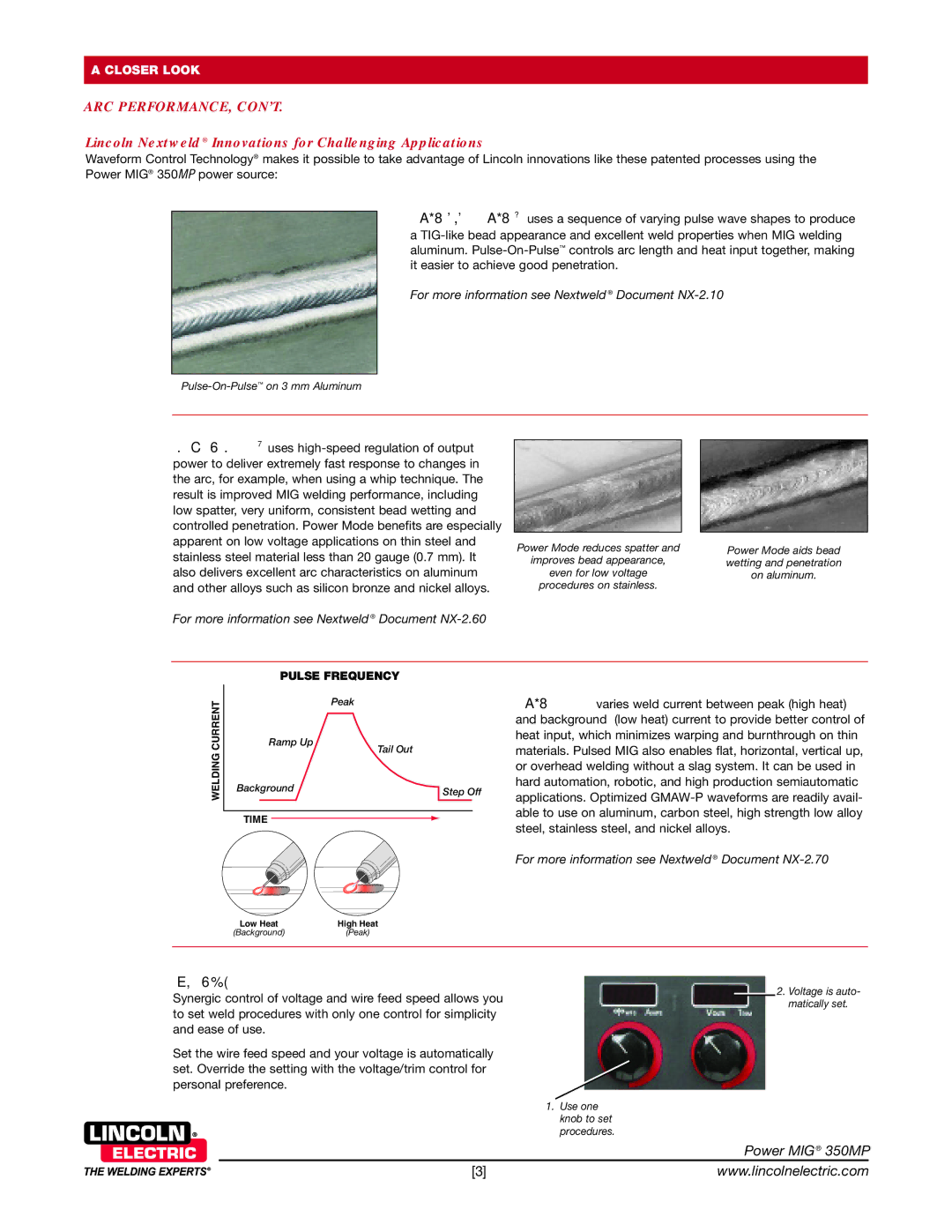

WELDING CURRENT

PULSE FREQUENCY

| Peak |

| Pulsed MIG varies weld current between peak (high heat) |

|

|

| and background (low heat) current to provide better control of |

Ramp Up |

|

| heat input, which minimizes warping and burnthrough on thin |

Tail Out |

| materials. Pulsed MIG also enables flat, horizontal, vertical up, | |

|

| ||

|

|

| or overhead welding without a slag system. It can be used in |

Background |

| Step Off | hard automation, robotic, and high production semiautomatic |

| applications. Optimized | ||

TIME |

| ||

|

| ||

|

| able to use on aluminum, carbon steel, high strength low alloy | |

|

| steel, stainless steel, and nickel alloys. | |

|

|

| For more information see Nextweld ® Document |

Low Heat | High Heat |

|

|

(Background) | (Peak) |

|

|

Synergic MIG

Synergic control of voltage and wire feed speed allows you to set weld procedures with only one control for simplicity and ease of use.

Set the wire feed speed and your voltage is automatically set. Override the setting with the voltage/trim control for personal preference.

2.Voltage is auto- matically set.

1.Use one knob to set procedures.

Power MIG® 350MP

[3] | www.lincolnelectric.com |