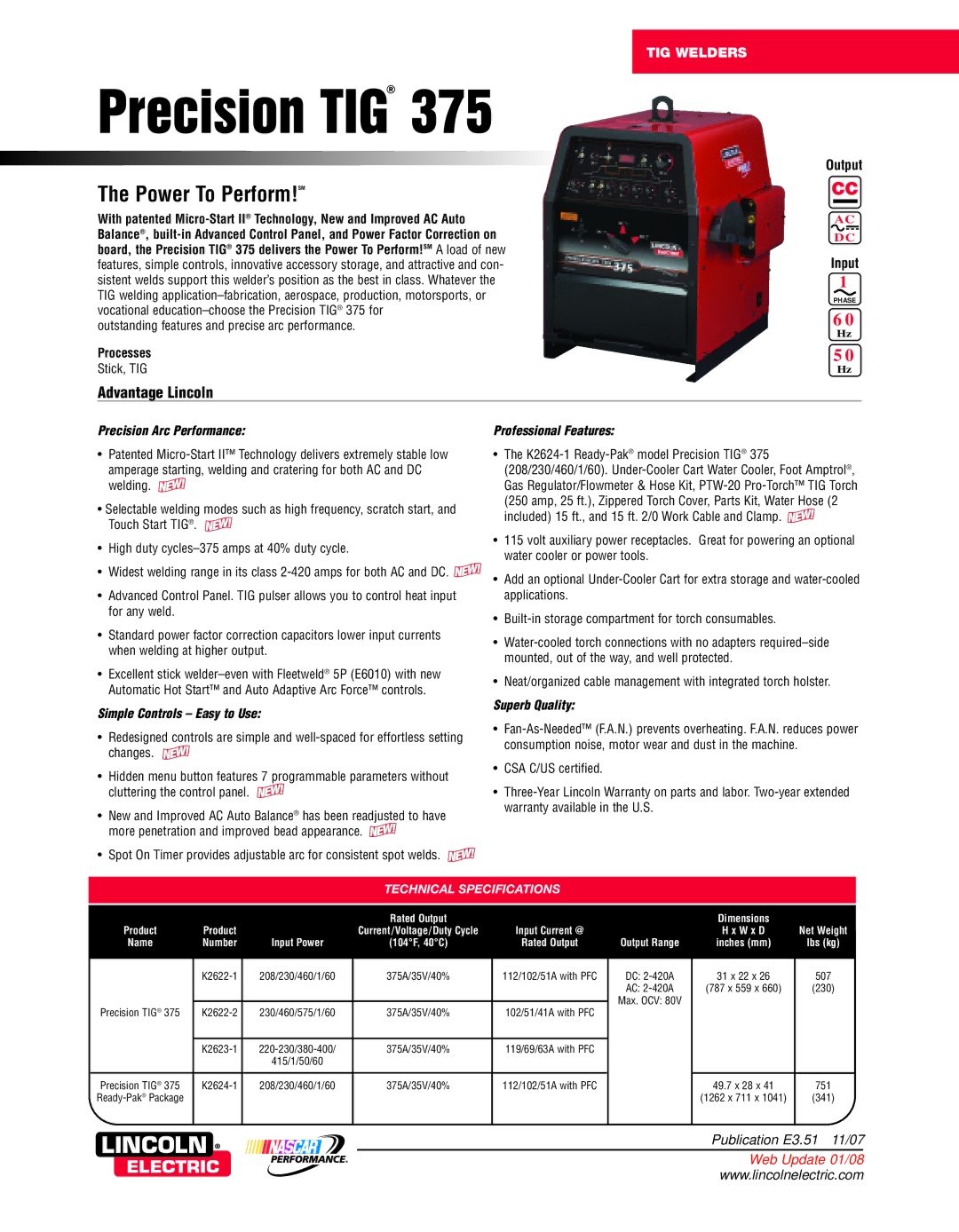

Precision TIG® 375 | TIG WELDERS |

|

The Power To Perform!SM

With patented

outstanding features and precise arc performance.

Processes

Stick, TIG

Advantage Lincoln

Output

AC

DC

Input

1

PHASE

60

Hz

50

Hz

Precision Arc Performance:

•Patented

amperage starting, welding and cratering for both AC and DC welding. ![]()

![]()

•Selectable welding modes such as high frequency, scratch start, and Touch Start TIG®. ![]()

![]()

•High duty

•Widest welding range in its class ![]()

![]()

•Advanced Control Panel. TIG pulser allows you to control heat input for any weld.

•Standard power factor correction capacitors lower input currents when welding at higher output.

•Excellent stick

Simple Controls – Easy to Use:

•Redesigned controls are simple and ![]()

![]()

•Hidden menu button features 7 programmable parameters without cluttering the control panel. ![]()

![]()

•New and Improved AC Auto Balance® has been readjusted to have more penetration and improved bead appearance. ![]()

![]()

•Spot On Timer provides adjustable arc for consistent spot welds. ![]()

![]()

Professional Features:

•The

(250 amp, 25 ft.), Zippered Torch Cover, Parts Kit, Water Hose (2 included) 15 ft., and 15 ft. 2/0 Work Cable and Clamp. ![]()

![]()

•115 volt auxiliary power receptacles. Great for powering an optional water cooler or power tools.

•Add an optional

•

•

•Neat/organized cable management with integrated torch holster.

Superb Quality:

•

•CSA C/US certified.

•

TECHNICAL SPECIFICATIONS

|

|

| Rated Output |

|

| Dimensions |

|

Product | Product |

| Current /Voltage/ Duty Cycle | Input Current @ |

| H x W x D | Net Weight |

Name | Number | Input Power | (104°F, 40°C) | Rated Output | Output Range | inches (mm) | lbs (kg) |

|

|

|

|

|

|

|

|

| 208/230/460/1/60 | 375A/35V/40% | 112/102/51A with PFC | ||

|

|

|

|

|

|

Precision TIG® 375 | 230/460/575/1/60 | 375A/35V/40% | 102/51/41A with PFC | ||

|

|

|

|

|

|

| 375A/35V/40% | 119/69/63A with PFC | |||

|

| 415/1/50/60 |

|

|

|

|

|

|

|

|

|

Precision TIG® 375 | 208/230/460/1/60 | 375A/35V/40% | 112/102/51A with PFC | ||

|

|

|

|

| |

DC:

AC:

Max. OCV: 80V

31 x 22 x 26 | 507 |

(787 x 559 x 660) | (230) |

49.7 x 28 x 41 | 751 |

(1262 x 711 x 1041) | (341) |

P ublication | E3.51 | 11/07 |

| W eb | Update | 01/08 |

www | .lincolnelectric.com |

| |