A CLOSER LOOK

A RC PE RFO RM AN CE

M icr o- StartII™ Te ch nol o gy — More than ju sta starting aid.

Better control for starting, arc stability and crater fill.

IN NOW CLUDES for AC WALUMINUM ELDING

Great Starting

Micro-Start II™ Technology minimizes high

frequency and ‘hot starts’ to deliver soft arc starts without arc wandering for AC and DC welding.

Stable, Focused Arc

THROUGHOUT THE WELD CYCLE –

even at the lowest amperage!

Precise Crater Fill

controlled ramp down helps precisely fill

the weld crater for quality results.

“ Set ItSee/ It” Pulse Con tro l — Make | attracti ve and c on sistentwe lds! |

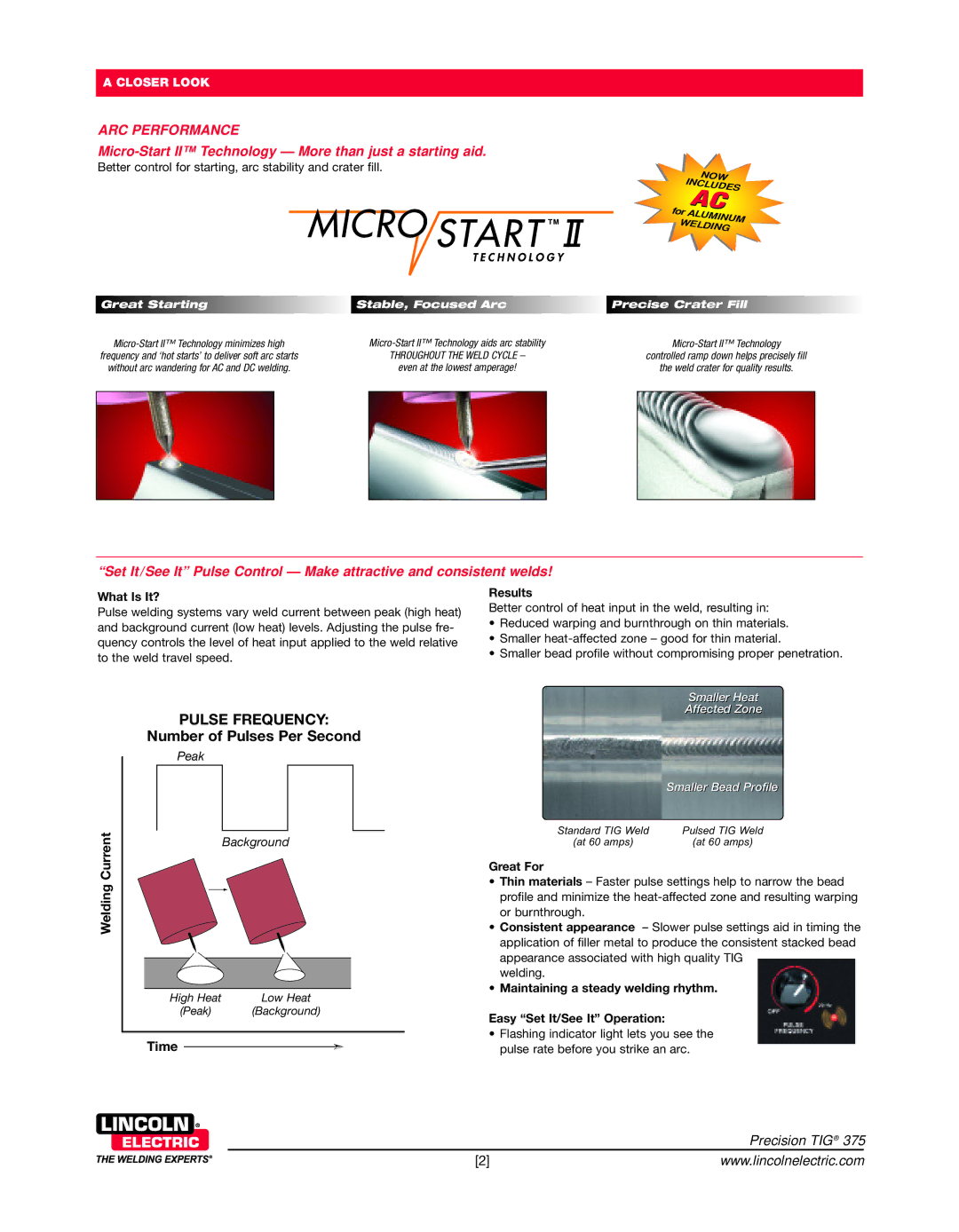

What Is It?

Pulse welding systems vary weld current between peak (high heat) and background current (low heat) levels. Adjusting the pulse fre- quency controls the level of heat input applied to the weld relative to the weld travel speed.

Results

Better control of heat input in the weld, resulting in:

•Reduced warping and burnthrough on thin materials.

•Smaller

•Smaller bead profile without compromising proper penetration.

PULSE FREQUENCY:

Number of Pulses Per Second

Peak |

|

Welding Current | Background |

| |

High Heat | Low Heat |

(Peak) | (Background) |

Time |

|

Smaller Heat

Affected Zone

| Smaller Bead Profile |

Standard TIG Weld | Pulsed TIG Weld |

(at 60 amps) | (at 60 amps) |

Great For

•Thin materials – Faster pulse settings help to narrow the bead profile and minimize the

•Consistent appearance – Slower pulse settings aid in timing the application of filler metal to produce the consistent stacked bead appearance associated with high quality TIG

welding.

•Maintaining a steady welding rhythm.

Easy “Set It/See It” Operation:

•Flashing indicator light lets you see the pulse rate before you strike an arc.

|

| Pr eci sion | TI G ® 375 |

[2] | www | .lincolnelectric.com | |