OPERATION | ||

|

|

|

Welding Process

Stick (Constant Current) Welding

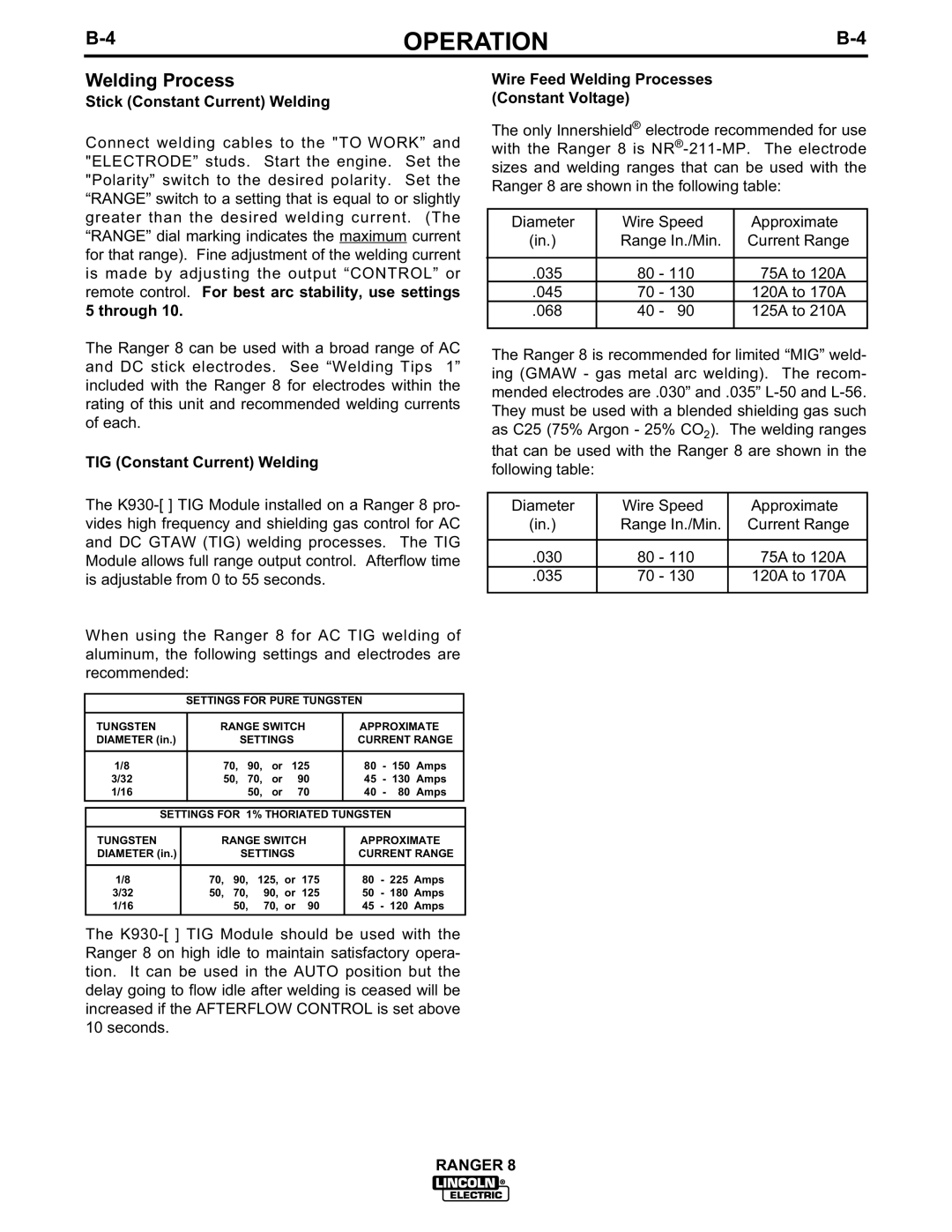

Connect welding cables to the "TO WORK” and "ELECTRODE” studs. Start the engine. Set the "Polarity” switch to the desired polarity. Set the “RANGE” switch to a setting that is equal to or slightly greater than the desired welding current. (The “RANGE” dial marking indicates the maximum current for that range). Fine adjustment of the welding current is made by adjusting the output “CONTROL” or remote control. For best arc stability, use settings 5 through 10.

The Ranger 8 can be used with a broad range of AC and DC stick electrodes. See “Welding Tips 1” included with the Ranger 8 for electrodes within the rating of this unit and recommended welding currents of each.

TIG (Constant Current) Welding

The

When using the Ranger 8 for AC TIG welding of aluminum, the following settings and electrodes are recommended:

SETTINGS FOR PURE TUNGSTEN

TUNGSTEN | RANGE SWITCH |

| APPROXIMATE | |||||||

DIAMETER (in.) |

|

| SETTINGS |

|

| CURRENT RANGE | ||||

|

|

|

|

|

|

|

| |||

1/8 |

| 70, | 90, | or 125 | 80 | - 150 Amps | ||||

3/32 |

| 50, | 70, | or | 90 | 45 | - 130 Amps | |||

1/16 |

|

|

| 50, | or | 70 | 40 | - 80 Amps | ||

|

|

|

| |||||||

SETTINGS FOR 1% THORIATED TUNGSTEN |

| |||||||||

|

|

|

|

| ||||||

TUNGSTEN |

| RANGE SWITCH |

| APPROXIMATE | ||||||

DIAMETER (in.) |

|

|

| SETTINGS |

|

| CURRENT RANGE | |||

|

|

|

|

|

|

|

| |||

1/8 |

| 70, | 90, 125, or 175 |

| 80 | - 225 | Amps | |||

3/32 |

| 50, | 70, | 90, or 125 |

| 50 | - 180 | Amps | ||

1/16 |

|

| 50, | 70, or | 90 |

| 45 | - 120 | Amps | |

The

Wire Feed Welding Processes

(Constant Voltage)

The only Innershield® electrode recommended for use with the Ranger 8 is

Diameter | Wire Speed | Approximate | |

(in.) | Range In./Min. | Current Range | |

|

|

|

|

.035 | 80 | - 110 | 75A to 120A |

.045 | 70 | - 130 | 120A to 170A |

.068 | 40 | - 90 | 125A to 210A |

|

|

|

|

The Ranger 8 is recommended for limited “MIG” weld- ing (GMAW - gas metal arc welding). The recom- mended electrodes are .030” and .035”

Diameter | Wire Speed | Approximate |

(in.) | Range In./Min. | Current Range |

|

|

|

.030 | 80 - 110 | 75A to 120A |

.035 | 70 - 130 | 120A to 170A |

|

|

|