CV320-I specifications

The Lincoln Electric CV320-I is a versatile and robust constant voltage power source designed primarily for semi-automatic and automatic welding applications. This machine is widely appreciated for its reliability, efficiency, and cutting-edge technologies, making it a preferred choice in various industrial settings.One of the standout features of the CV320-I is its advanced inverter technology. This innovative design allows for a more lightweight and compact machine while maintaining high performance levels. The inverter technology improves energy efficiency, resulting in lower operational costs over time. Moreover, its compact size makes transportation and handling easier, especially in job site scenarios where space is at a premium.

Another significant characteristic of the CV320-I is its arc stability. Equipped with sophisticated control circuitry, the machine delivers a consistent arc throughout the welding process. This leads to improved weld quality, reduced spatter, and a cleaner finish. The machine also features a wide voltage range, accommodating various welding processes such as MIG and TIG welding, making it versatile for different applications.

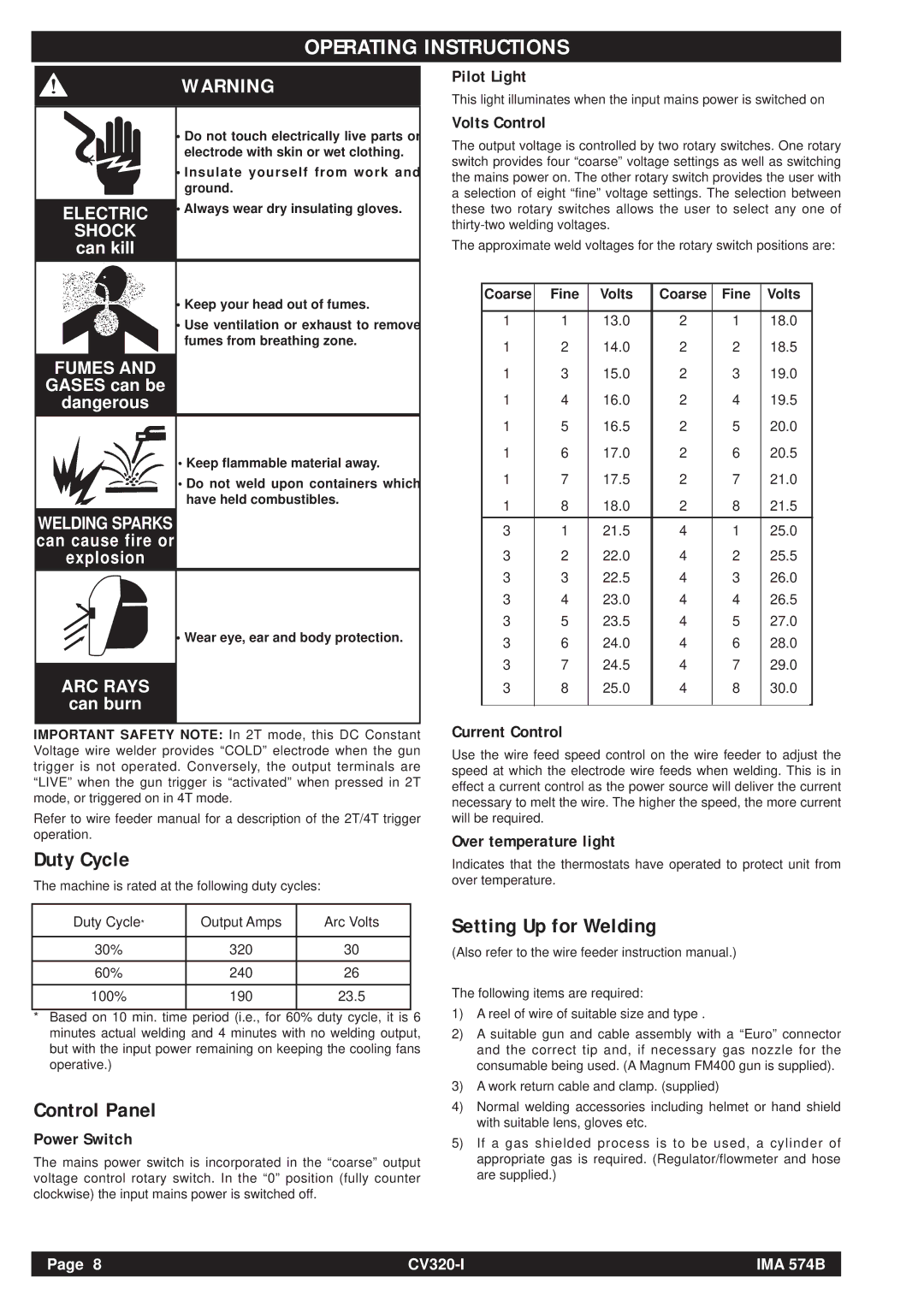

The CV320-I offers impressive output ratings, providing the power needed for heavy-duty tasks. It delivers excellent performance with a duty cycle suitable for continuous use, allowing operators to work longer without interruptions. Additionally, it includes quick disconnects for easy setup and breakdown, enhancing productivity.

Another crucial aspect of the CV320-I is its user-friendly interface. The control panel is intuitively designed, featuring clearly labeled knobs and settings that allow even novice operators to adjust parameters with ease. This simplicity enhances efficiency on the shop floor, reducing downtime associated with complicated setups.

The machine also offers a range of safety features, such as thermal overload protection and output voltage sensing, to ensure both operator safety and equipment longevity. The durable construction and high-quality components further contribute to the machine's ruggedness and reliability in various industrial environments.

In summary, the Lincoln Electric CV320-I is an exceptional welding power source that combines innovative technology, user-friendly design, and robust performance. Its inverter technology, arc stability, and safety features make it an ideal choice for demanding welding applications, ensuring satisfactory results for professionals in the field.