D1.8 Seismic Supplement Welding Manual

23

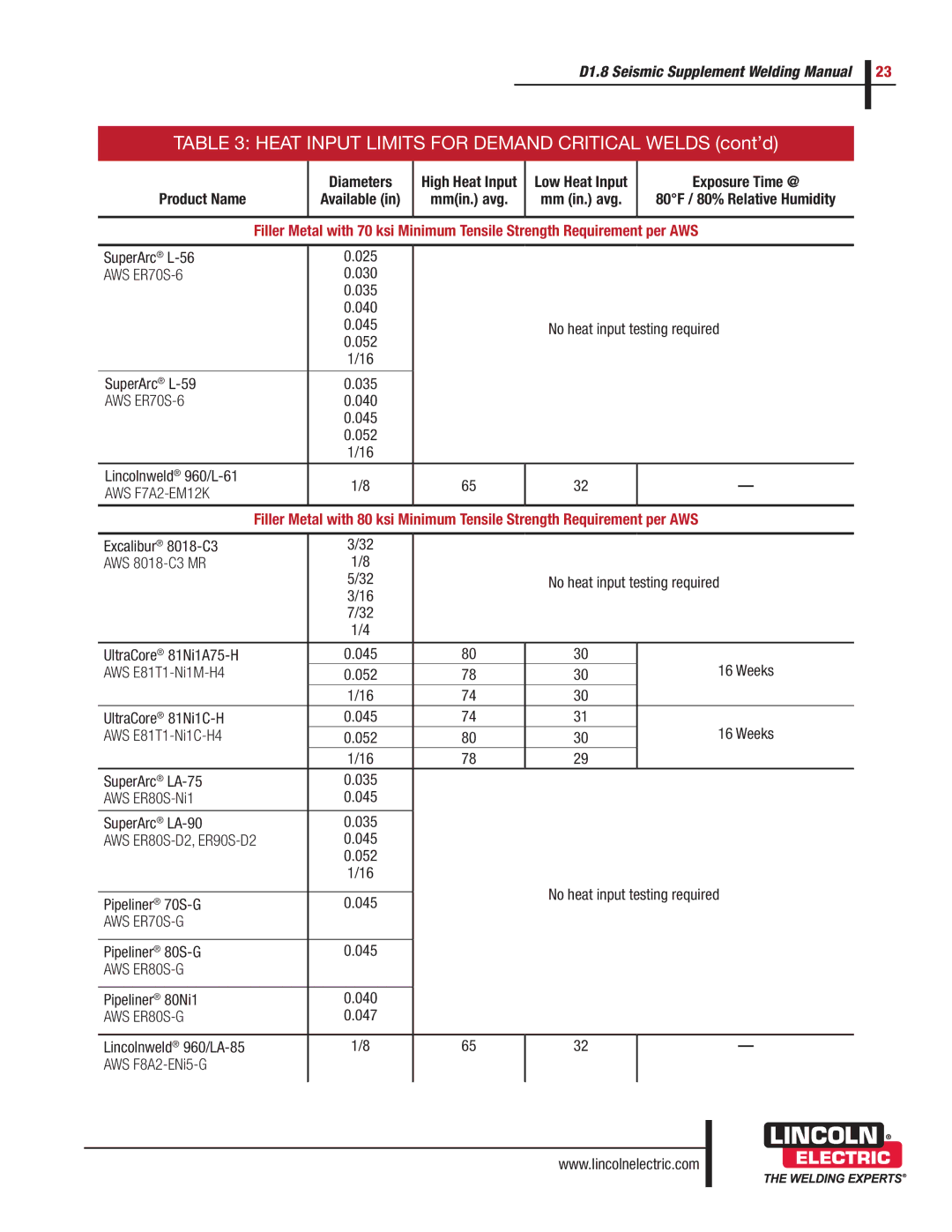

TABLE 3: HEAT INPUT LIMITS FOR DEMAND CRITICAL WELDS (cont’d)

.

Product Name

Diameters . Available (in)

High Heat Input mm(in.) avg.

Low Heat Input mm (in.) avg.

Exposure Time @. 80°F / 80% Relative Humidity

Filler Metal with 70 ksi Minimum Tensile Strength Requirement per AWS |

| ||||

|

|

|

|

|

|

SuperArc® | 0.025 |

|

|

|

|

AWS | 0.030 |

|

|

|

|

| 0.035 |

|

|

|

|

| 0.040 |

|

|

|

|

| 0.045 |

| No heat input testing required | ||

| 0.052 |

| |||

|

|

|

|

| |

| 1/16 |

|

|

|

|

|

|

|

|

|

|

SuperArc® | 0.035 |

|

|

|

|

AWS | 0.040 |

|

|

|

|

| 0.045 |

|

|

|

|

| 0.052 |

|

|

|

|

| 1/16 |

|

|

|

|

|

|

|

|

|

|

Lincolnweld® | 1/8 | 65 | 32 |

| — |

AWS |

| ||||

|

|

|

|

| |

|

|

|

|

|

|

Filler Metal with 80 ksi Minimum Tensile Strength Requirement per AWS |

| ||||

|

|

|

|

|

|

Excalibur® | 3/32 |

|

|

|

|

AWS | 1/8 |

|

|

|

|

| 5/32 |

| No heat input testing required | ||

| 3/16 |

|

|

|

|

| 7/32 |

|

|

|

|

| 1/4 |

|

|

|

|

|

|

|

|

|

|

UltraCore® | 0.045 | 80 | 30 |

| 16 Weeks |

AWS | 0.052 | 78 | 30 |

| |

| 1/16 | 74 | 30 |

|

|

UltraCore® | 0.045 | 74 | 31 |

| 16 Weeks |

AWS | 0.052 | 80 | 30 |

| |

| 1/16 | 78 | 29 |

|

|

SuperArc® | 0.035 |

|

|

|

|

AWS | 0.045 |

|

|

|

|

|

|

|

|

|

|

SuperArc® | 0.035 |

|

|

|

|

AWS | 0.045 |

|

|

|

|

| 0.052 |

|

|

|

|

| 1/16 |

|

|

|

|

|

|

| No heat input testing required | ||

Pipeliner® | 0.045 |

| |||

|

|

|

| ||

AWS |

|

|

|

|

|

|

|

|

|

|

|

Pipeliner® | 0.045 |

|

|

|

|

AWS |

|

|

|

|

|

|

|

|

|

|

|

Pipeliner® 80Ni1 | 0.040 |

|

|

|

|

AWS | 0.047 |

|

|

|

|

|

|

|

|

|

|

Lincolnweld® | 1/8 | 65 | 32 |

| — |

AWS |

|

|

|

|

|

|

|

|

|

|

|

www.lincolnelectric.com