OPERATION | ||

|

|

|

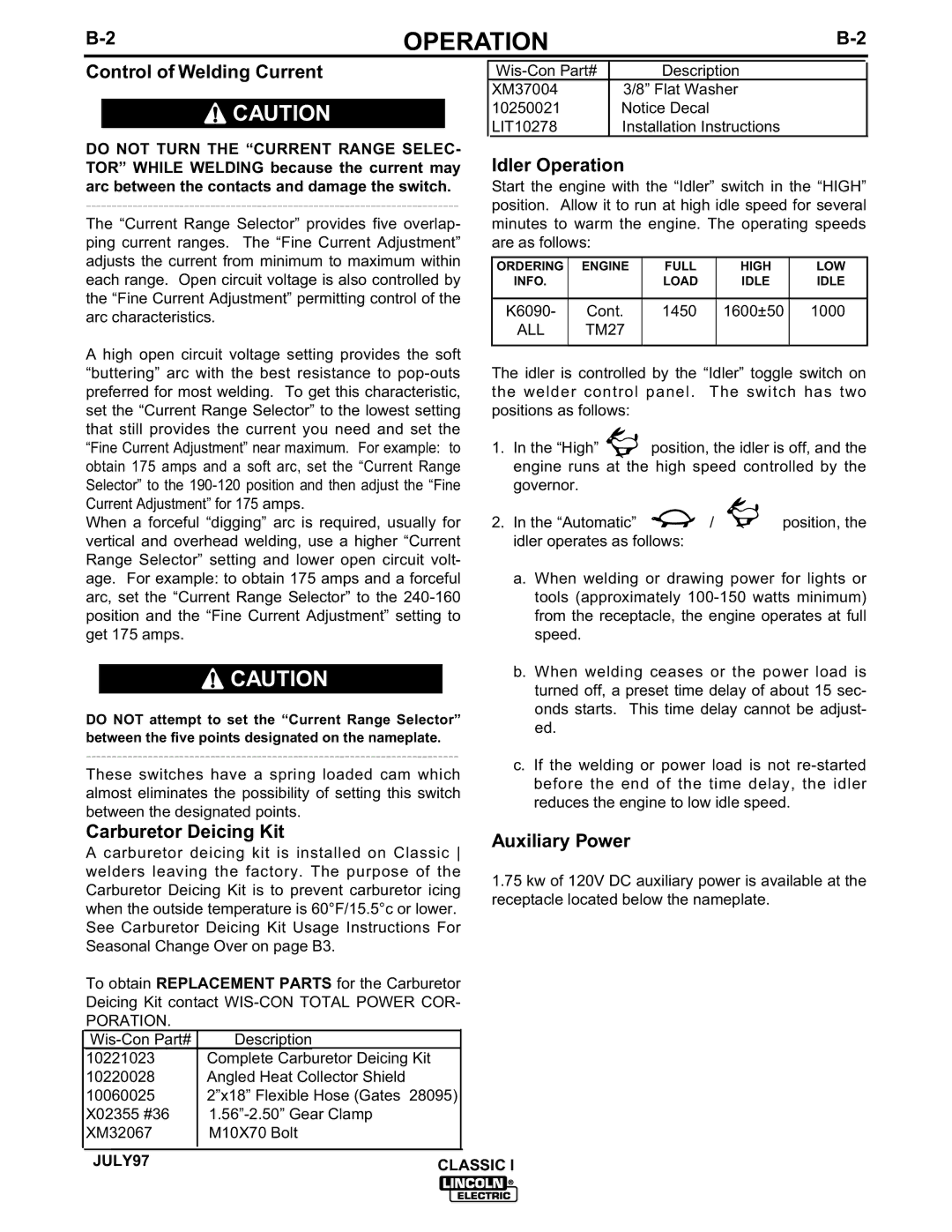

Control of Welding Current

![]() CAUTION

CAUTION

DO NOT TURN THE “CURRENT RANGE SELEC- TOR” WHILE WELDING because the current may arc between the contacts and damage the switch.

The “Current Range Selector” provides five overlap- ping current ranges. The “Fine Current Adjustment” adjusts the current from minimum to maximum within each range. Open circuit voltage is also controlled by the “Fine Current Adjustment” permitting control of the arc characteristics.

A high open circuit voltage setting provides the soft “buttering” arc with the best resistance to

When a forceful “digging” arc is required, usually for vertical and overhead welding, use a higher “Current Range Selector” setting and lower open circuit volt- age. For example: to obtain 175 amps and a forceful arc, set the “Current Range Selector” to the

![]() CAUTION

CAUTION

DO NOT attempt to set the “Current Range Selector” between the five points designated on the nameplate.

These switches have a spring loaded cam which almost eliminates the possibility of setting this switch between the designated points.

Description | |

XM37004 | 3/8” Flat Washer |

10250021 | Notice Decal |

LIT10278 | Installation Instructions |

Idler Operation

Start the engine with the “Idler” switch in the “HIGH” position. Allow it to run at high idle speed for several minutes to warm the engine. The operating speeds are as follows:

ORDERING | ENGINE | FULL | HIGH | LOW |

INFO. |

| LOAD | IDLE | IDLE |

|

|

|

|

|

K6090- | Cont. | 1450 | 1600±50 | 1000 |

ALL | TM27 |

|

|

|

|

|

|

|

|

The idler is controlled by the “Idler” toggle switch on the welder control panel. The switch has two positions as follows:

1.In the “High” ![]() position, the idler is off, and the engine runs at the high speed controlled by the governor.

position, the idler is off, and the engine runs at the high speed controlled by the governor.

2. In the “Automatic” | / | position, the |

idler operates as follows: |

|

|

a. When welding or drawing power for lights or tools (approximately

b. When welding ceases or the power load is turned off, a preset time delay of about 15 sec- onds starts. This time delay cannot be adjust- ed.

c.If the welding or power load is not

Carburetor Deicing Kit

A carburetor deicing kit is installed on Classic welders leaving the factory. The purpose of the Carburetor Deicing Kit is to prevent carburetor icing when the outside temperature is 60°F/15.5°c or lower. See Carburetor Deicing Kit Usage Instructions For Seasonal Change Over on page B3.

To obtain REPLACEMENT PARTS for the Carburetor Deicing Kit contact

PORATION.

Description | |

10221023 | Complete Carburetor Deicing Kit |

10220028 | Angled Heat Collector Shield |

10060025 | 2”x18” Flexible Hose (Gates 28095) |

X02355 #36 | |

XM32067 | M10X70 Bolt |

Auxiliary Power

1.75kw of 120V DC auxiliary power is available at the receptacle located below the nameplate.

JULY97 | CLASSIC I |