4 | INSTALLATION | 4 |

|

|

|

INPUT LEADS L1 & L2 | |

| INPUT SUPPLY |

| CONNECTION |

H2 | H4 |

H3 | |

FOR

(SEE INPUT SUPPLYCONNECTION SECTION) FOR 380V: CONNECT COPPER LINK TO H3

FOR

FIGURE A.1 Reconnect Leads

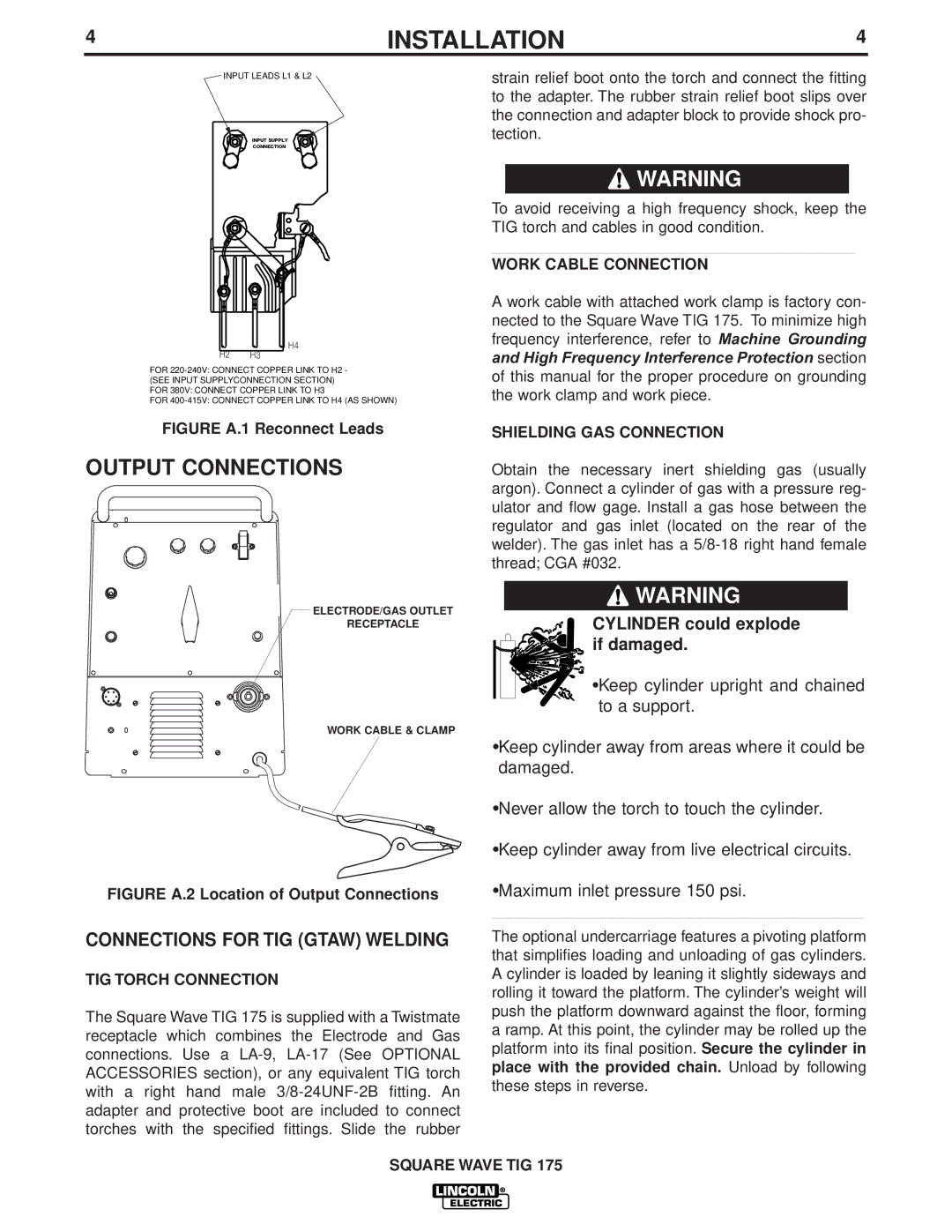

OUTPUT CONNECTIONS

ELECTRODE/GAS OUTLET

RECEPTACLE

WORK CABLE & CLAMP

FIGURE A.2 Location of Output Connections

CONNECTIONS FOR TIG (GTAW) WELDING

TIG TORCH CONNECTION

The Square Wave TIG 175 is supplied with a Twistmate receptacle which combines the Electrode and Gas connections. Use a

strain relief boot onto the torch and connect the fitting to the adapter. The rubber strain relief boot slips over the connection and adapter block to provide shock pro- tection.

![]() WARNING

WARNING

To avoid receiving a high frequency shock, keep the TIG torch and cables in good condition.

__________________________________________

WORK CABLE CONNECTION

A work cable with attached work clamp is factory con- nected to the Square Wave TIG 175. To minimize high frequency interference, refer to Machine Grounding and High Frequency Interference Protection section of this manual for the proper procedure on grounding the work clamp and work piece.

SHIELDING GAS CONNECTION

Obtain the necessary inert shielding gas (usually argon). Connect a cylinder of gas with a pressure reg- ulator and flow gage. Install a gas hose between the regulator and gas inlet (located on the rear of the welder). The gas inlet has a

![]() WARNING

WARNING

CYLINDER could explode if damaged.

•Keep cylinder upright and chained to a support.

•Keep cylinder away from areas where it could be damaged.

•Never allow the torch to touch the cylinder.

•Keep cylinder away from live electrical circuits.

•Maximum inlet pressure 150 psi.

___________________________________________

The optional undercarriage features a pivoting platform that simplifies loading and unloading of gas cylinders. A cylinder is loaded by leaning it slightly sideways and rolling it toward the platform. The cylinder’s weight will push the platform downward against the floor, forming a ramp. At this point, the cylinder may be rolled up the platform into its final position. Secure the cylinder in place with the provided chain. Unload by following these steps in reverse.