MAINTENANCE | ||

|

|

|

SAFETY PRECAUTIONS

![]() WARNING

WARNING

•Have qualified personnel do all maintenance and troubleshooting work.

•Turn the engine off before working inside the machine or servicing the engine.

•Remove guards only when necessary to perform maintenance and replace them when the mainte-

![]() nance requiring their removal is complete. If guards are missing from the machine, obtain replacements from a

nance requiring their removal is complete. If guards are missing from the machine, obtain replacements from a

Lincoln Distributor. (See Operating Manual Parts List.)

•Read the Safety Precautions in the front of this manual and in the Engine Owner’s Manual before working on this machine.

•Keep all equipment safety guards, covers, and devices in position and in good repair. Keep hands, hair, clothing, and tools away from the gears, fans, and all other moving parts when starting, operating, or repairing the equipment.

Routine Maintenance

At the end of each day’s use, refill the fuel tank to minimize moisture condensation in the tank. Running out of fuel tends to draw dirt into the fuel system. Also, check the crankcase oil level and add oil if indicated.

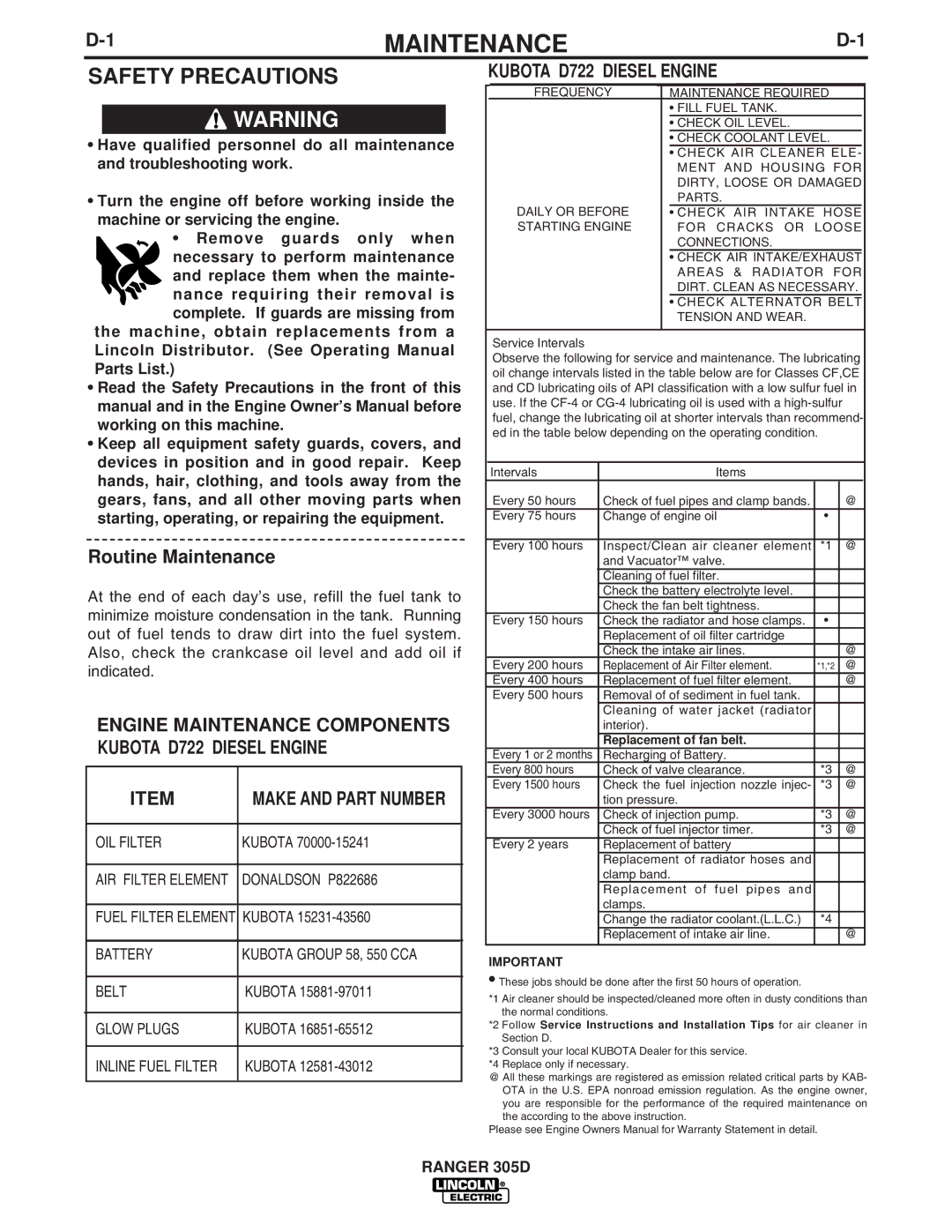

ENGINE MAINTENANCE COMPONENTS KUBOTA D722 DIESEL ENGINE

ITEM | MAKE AND PART NUMBER |

|

|

OIL FILTER | KUBOTA |

|

|

AIR FILTER ELEMENT | DONALDSON P822686 |

|

|

FUEL FILTER ELEMENT | KUBOTA |

|

|

BATTERY | KUBOTA GROUP 58, 550 CCA |

|

|

BELT | KUBOTA |

|

|

GLOW PLUGS | KUBOTA |

|

|

INLINE FUEL FILTER | KUBOTA |

|

|

KUBOTA D722 DIESEL ENGINE

| FREQUENCY |

| MAINTENANCE REQUIRED | ||

|

|

| • FILL FUEL TANK. | ||

|

|

| • CHECK OIL LEVEL. |

| |

|

|

| • CHECK COOLANT LEVEL. |

| |

|

|

| • CHECK AIR CLEANER ELE- |

| |

|

|

|

| MENT AND HOUSING FOR | |

|

|

|

| DIRTY, LOOSE OR DAMAGED | |

|

|

|

| PARTS. | |

| DAILY OR BEFORE |

|

| • CHECK AIR INTAKE HOSE |

|

| STARTING ENGINE |

|

| FOR CRACKS OR LOOSE | |

|

|

|

| CONNECTIONS. | |

|

|

|

| • CHECK AIR INTAKE/EXHAUST |

|

|

|

|

| AREAS & RADIATOR FOR | |

|

|

|

| DIRT. CLEAN AS NECESSARY. | |

|

|

|

| • CHECK ALTERNATOR BELT |

|

|

|

|

| TENSION AND WEAR. | |

|

|

|

|

|

|

Service Intervals

Observe the following for service and maintenance. The lubricating oil change intervals listed in the table below are for Classes CF,CE and CD lubricating oils of API classification with a low sulfur fuel in use. If the

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Intervals |

|

|

| Items |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Every 50 hours |

|

| Check of fuel pipes and clamp bands. |

| @ | ||||

|

|

| Every 75 hours |

|

| Change of engine oil | • |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

| Every 100 hours |

|

| Inspect/Clean air cleaner element | *1 |

| @ |

| ||

|

|

|

|

|

| and Vacuator™ valve. |

|

|

|

|

| |

|

|

|

|

|

| Cleaning of fuel filter. |

|

|

|

|

| |

|

|

|

|

|

| Check the battery electrolyte level. |

|

|

|

|

| |

|

|

|

|

|

| Check the fan belt tightness. |

|

|

|

|

| |

|

|

| Every 150 hours |

|

| Check the radiator and hose clamps. | • |

|

|

|

| |

|

|

|

|

|

| Replacement of oil filter cartridge |

|

|

|

|

| |

|

|

|

|

|

| Check the intake air lines. |

|

| @ |

| ||

|

|

| Every 200 hours |

|

| Replacement of Air Filter element. | *1,*2 |

| @ |

| ||

|

|

| Every 400 hours |

|

| Replacement of fuel filter element. |

|

| @ |

| ||

|

|

| Every 500 hours |

|

| Removal of of sediment in fuel tank. |

|

|

|

|

| |

|

|

|

|

|

| Cleaning of water jacket (radiator |

|

|

|

|

| |

|

|

|

|

|

| interior). |

|

|

|

|

| |

|

|

|

|

|

| Replacement of fan belt. |

|

|

|

|

| |

|

|

| Every 1 or 2 months |

|

| Recharging of Battery. |

|

|

|

|

| |

|

|

| Every 800 hours |

|

| Check of valve clearance. | *3 |

| @ |

| ||

|

|

| Every 1500 hours |

|

| Check the fuel injection nozzle injec- | *3 |

| @ |

| ||

|

|

|

|

|

| tion pressure. |

|

|

|

|

| |

|

|

| Every 3000 hours |

|

| Check of injection pump. | *3 |

| @ |

| ||

|

|

|

|

|

| Check of fuel injector timer. | *3 |

| @ |

| ||

|

|

| Every 2 years |

|

| Replacement of battery |

|

|

|

|

| |

|

|

|

|

|

| Replacement of radiator hoses and |

|

|

|

|

| |

|

|

|

|

|

| clamp band. |

|

|

|

|

| |

|

|

|

|

|

| Replacement of fuel pipes and |

|

|

|

|

| |

|

|

|

|

|

| clamps. |

|

|

|

|

| |

|

|

|

|

|

| Change the radiator coolant.(L.L.C.) | *4 |

|

|

|

| |

|

|

|

|

|

| Replacement of intake air line. |

|

| @ |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IMPORTANT

•These jobs should be done after the first 50 hours of operation.

*1 Air cleaner should be inspected/cleaned more often in dusty conditions than the normal conditions.

*2 Follow Service Instructions and Installation Tips for air cleaner in Section D.

*3 Consult your local KUBOTA Dealer for this service.

*4 Replace only if necessary.

@All these markings are registered as emission related critical parts by KAB- OTA in the U.S. EPA nonroad emission regulation. As the engine owner, you are responsible for the performance of the required maintenance on the according to the above instruction.

Please see Engine Owners Manual for Warranty Statement in detail.