OPERATION | ||

|

|

|

When in the TOUCH START TIG mode and when a Amptrol is connected to the

The ARC CONTROL is not active in the TIG mode.

The Ranger 305D can be used in a wide variety of DC TIG welding applications. In general the ‘Touch Start’ feature allows contamination free starting without the use of a

Ranger 305D settings when using the

•Set the MODE Switch to the TOUCH START TIG setting.

•Set the "IDLER" Switch to the "AUTO" position.

•Set the "WELDING TERMINALS" switch to the "REMOTELY CONTROLLED" position. This will keep the "Solid State" contactor open and provide a “cold” electrode until the Amptrol or Arc Start Switch is pressed

When using the TIG Module, the OUTPUT control on the Ranger 305D is used to set the maximum range of the CURRENT CONTROL on the TIG module or an Amptrol if connected to the TIG Module. (See Table B.2.)

WIRE WELDING-CV

Connect a wire feeder to the Ranger 305D according to the instructions in INSTALLATION INSTRUCTIONS Section.

The Ranger 305D in the

Contact your local authorized Lincoln Electric Distributor or the Lincoln Electric Company for specific wires used on certain applications with this machine. Also for additional information contact WWW.Lincolnelectric.com

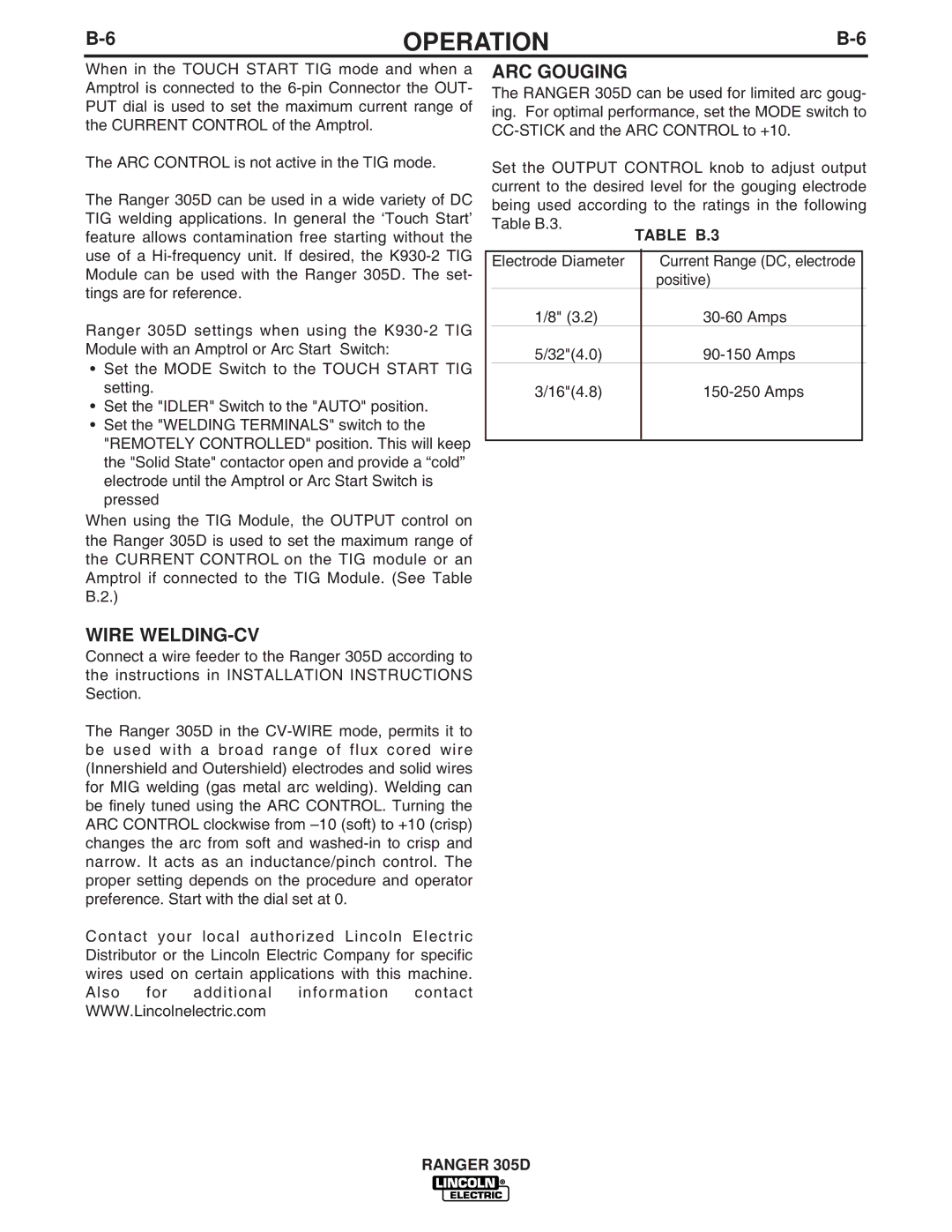

ARC GOUGING

The RANGER 305D can be used for limited arc goug- ing. For optimal performance, set the MODE switch to

Set the OUTPUT CONTROL knob to adjust output current to the desired level for the gouging electrode being used according to the ratings in the following Table B.3.

|

| TABLE B.3 | ||

Electrode Diameter |

| Current Range (DC, electrode |

| |

|

|

| positive) |

|

| 1/8" (3.2) |

|

| |

| 5/32"(4.0) |

|

| |

3/16"(4.8) |

|

| ||

|

|

|

|

|