INSTALLATION | ||

|

|

|

WELD CABLE CONNECTION

The size of the electrode cable and work cable must be sufficient for the maximum weld current and total cable length to be used. Refer to table A.1.

TABLE A.1

Weld Current |

| Total Cable Length |

| |

|

|

|

| |

|

|

|

| |

60% Duty Cycle | ||||

|

|

|

|

|

200Amps | 2 AWG | 2 AWG | 1 AWG | 1/0 |

300Amps | 1 AWG | 1 AWG | 1/0 | 2/0 |

400Amps | 2/0 | 2/0 | 3/0 | 3/0 |

500Amps | 2/0 | 3/0 | 3/0 | 4/0 |

|

|

|

|

|

ELECTRODE CABLE CONNECTION

Route the electrode cable through the oval hole in the

WORK CABLE CONNECTION

Connect a work lead of sufficient size between the proper output stud on the power source and the work. Be sure the connection to the work makes tight metal - to - metal electrical contact . Poor work lead connections can result in poor welding performance.

DRIVE ROLL INSTALLATION

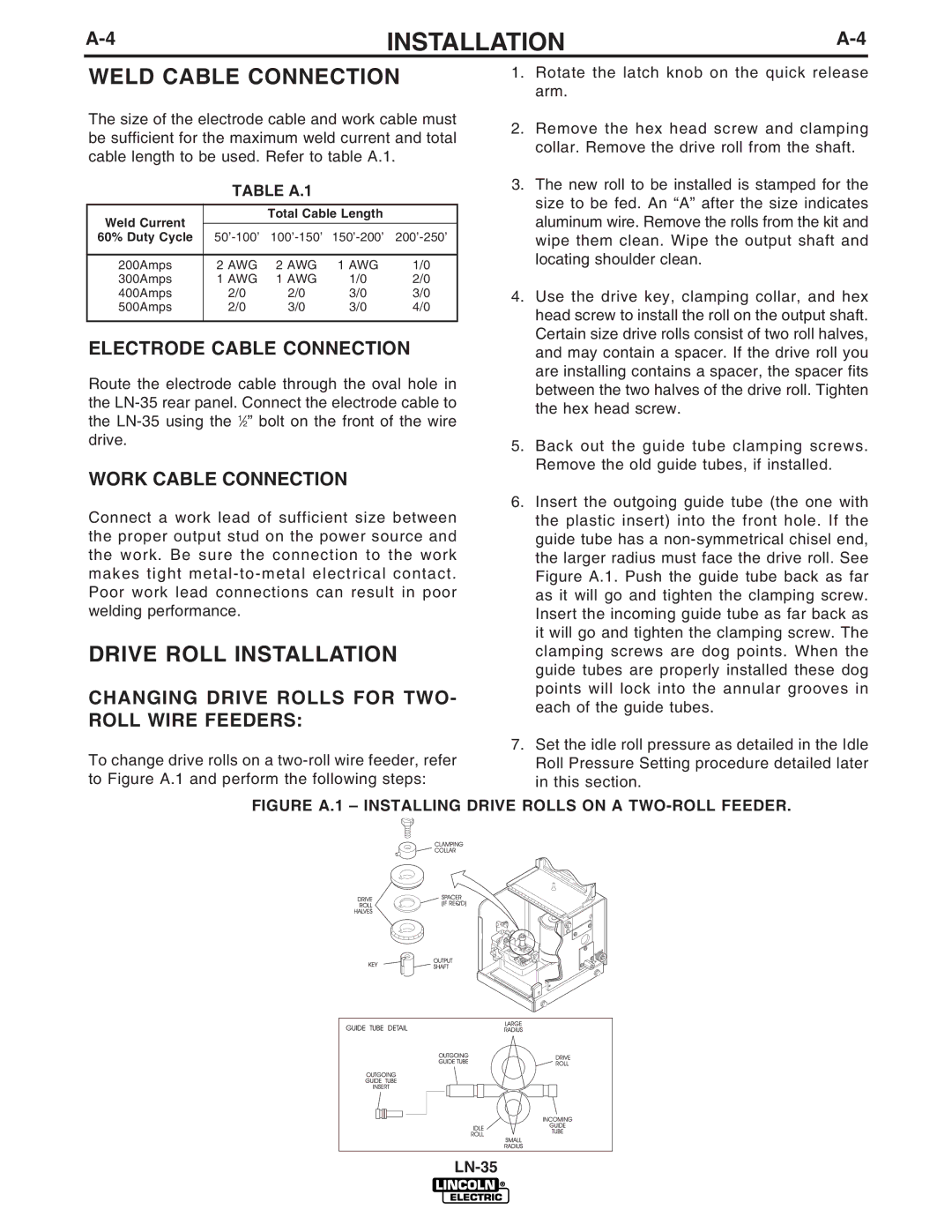

CHANGING DRIVE ROLLS FOR TWO- ROLL WIRE FEEDERS:

To change drive rolls on a

1.Rotate the latch knob on the quick release arm.

2.Remove the hex head screw and clamping collar. Remove the drive roll from the shaft.

3.The new roll to be installed is stamped for the size to be fed. An “A” after the size indicates aluminum wire. Remove the rolls from the kit and wipe them clean. Wipe the output shaft and locating shoulder clean.

4.Use the drive key, clamping collar, and hex head screw to install the roll on the output shaft. Certain size drive rolls consist of two roll halves, and may contain a spacer. If the drive roll you are installing contains a spacer, the spacer fits between the two halves of the drive roll. Tighten the hex head screw.

5.Back out the guide tube clamping screws. Remove the old guide tubes, if installed.

6.Insert the outgoing guide tube (the one with the plastic insert) into the front hole. If the guide tube has a

7.Set the idle roll pressure as detailed in the Idle Roll Pressure Setting procedure detailed later in this section.